A kind of graphene ultrafiltration membrane and preparation method thereof

A technology of graphene and ultrafiltration membranes, applied in ultrafiltration, chemical instruments and methods, membrane technology, etc., can solve problems such as poor stability, high energy consumption, and low separation efficiency, and achieve poor stability and strong anti-pollution performance , Improve the effect of interception rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

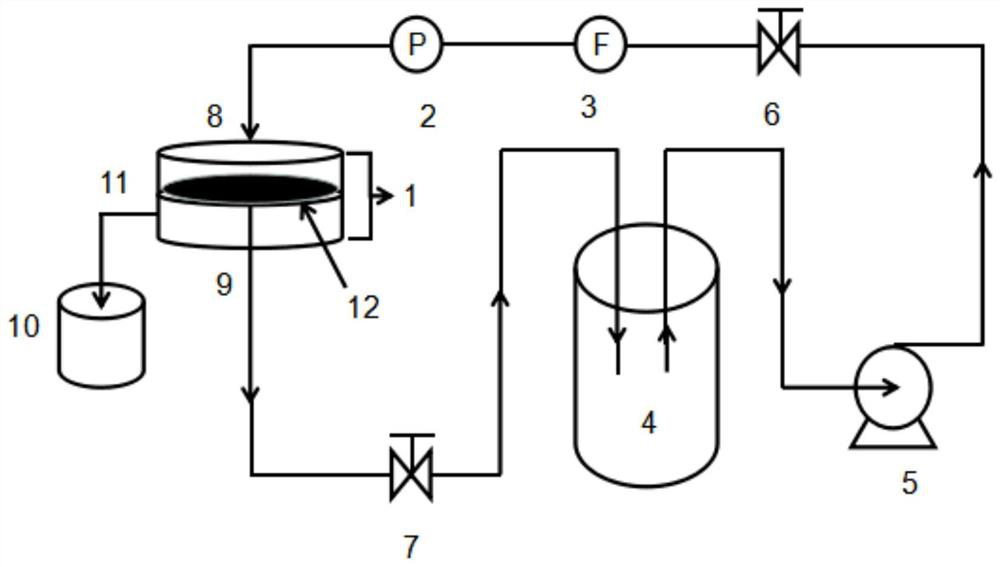

[0027] A kind of preparation method of graphene ultrafiltration membrane is as follows:

[0028] (1) Prepare 50 ml of graphene oxide aqueous solution with a concentration of 0.1 mg / L for ultrasonic dispersion, add 50 ul of hydrazine hydrate with a mass fraction of 50 wt % and 100 ul of ammonia with a mass fraction of 28 wt %, stir vigorously and mix uniformly, Under reaction for 4 hours, obtain partly reduced graphene oxide solution;

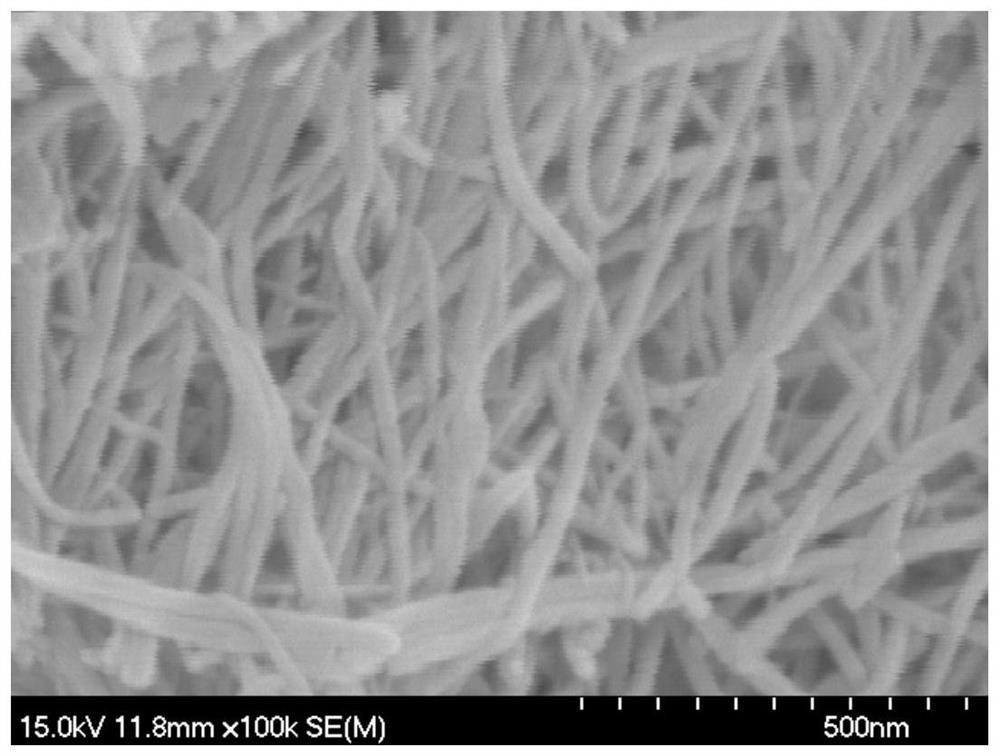

[0029] (2) Dissolve 0.108g of cadmium nitrate tetrahydrate in 20ml of aqueous solution, dissolve 0.0736g of hexamethylenetetramine in 15ml of aqueous solution, mix the two evenly, put them in a 50ml high-temperature reactor, and react at 105°C for 35h, The product was washed twice with water and ethanol and dried at room temperature for 24 hours to obtain cadmium hydroxide nanowires;

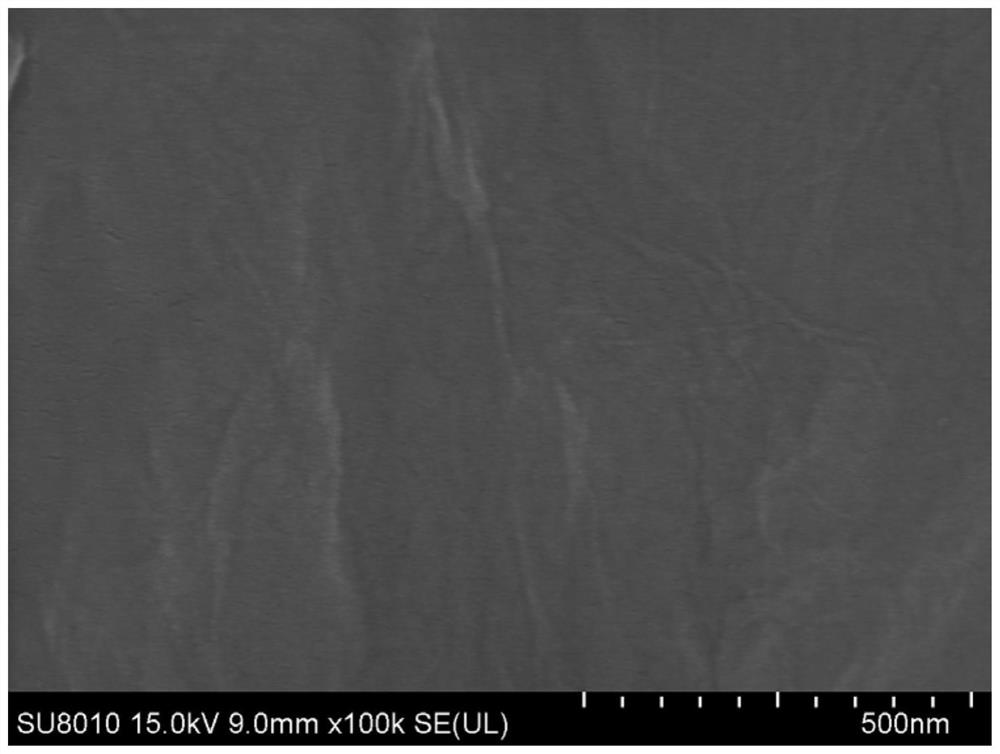

[0030] (3) Disperse 0.0025g of cadmium hydroxide nanowires in 50ml of aqueous solution, take 10ml of cadmium hydroxide nanowire dispersion and 1ml of the partial...

example 2

[0036] A kind of preparation method of graphene ultrafiltration membrane is as follows:

[0037] (1) Prepare 50 ml of graphene oxide aqueous solution with a concentration of 5 mg / L and ultrasonically disperse it uniformly, add 80 ul of hydrazine hydrate with a mass fraction of 50 wt % and 150 ul of ammonia with a mass fraction of 28 wt %, stir vigorously and mix uniformly, and heat the mixture at a temperature of 40 ° C React for 3 hours to obtain partially reduced graphene oxide.

[0038] (2) Dissolve 1.08g of cadmium nitrate tetrahydrate in 20ml of aqueous solution, dissolve 0.9813g of hexamethylenetetramine in 15ml of aqueous solution, mix the two evenly, put them in a 50ml high-temperature reactor, and react at 100°C for 48h, The product was washed twice with water and ethanol and dried at room temperature for 24 hours to obtain cadmium hydroxide nanowires.

[0039] (3) Disperse 0.001g of cadmium hydroxide nanowires in 50ml of aqueous solution, get 5ml of cadmium hydroxid...

example 3

[0042] A kind of preparation method of graphene ultrafiltration membrane is as follows:

[0043] (1) Prepare 50ml of graphene oxide aqueous solution with a concentration of 10mg / L and ultrasonically disperse it uniformly, add 120ul of hydrazine hydrate with a mass fraction of 50wt% and 200ul of ammonia with a mass fraction of 28wt%, stir vigorously and mix evenly, and heat at 60°C React for 2 hours to obtain partially reduced graphene oxide.

[0044] (2) Dissolve 2.1593g of cadmium nitrate tetrahydrate in 20ml of aqueous solution, dissolve 0.0491g of hexamethylenetetramine in 15ml of aqueous solution, mix the two evenly, put them in a 50ml high-temperature reaction kettle, and react at 180°C for 8h, The product was washed twice with water and ethanol, respectively, and dried at room temperature for 24 h to obtain cadmium hydroxide nanowires.

[0045](3) Disperse 0.0005g of cadmium hydroxide nanowires in 50ml of aqueous solution, take 5ml of cadmium hydroxide nanowire dispersi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com