Intelligent hammer crusher having remote monitoring function

A hammer crusher and remote monitoring technology, applied in the field of the Internet of Things, can solve the problem that the hammer crusher cannot monitor the production status and production key data in real time, and achieve the effect of real-time remote monitoring and reduction of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

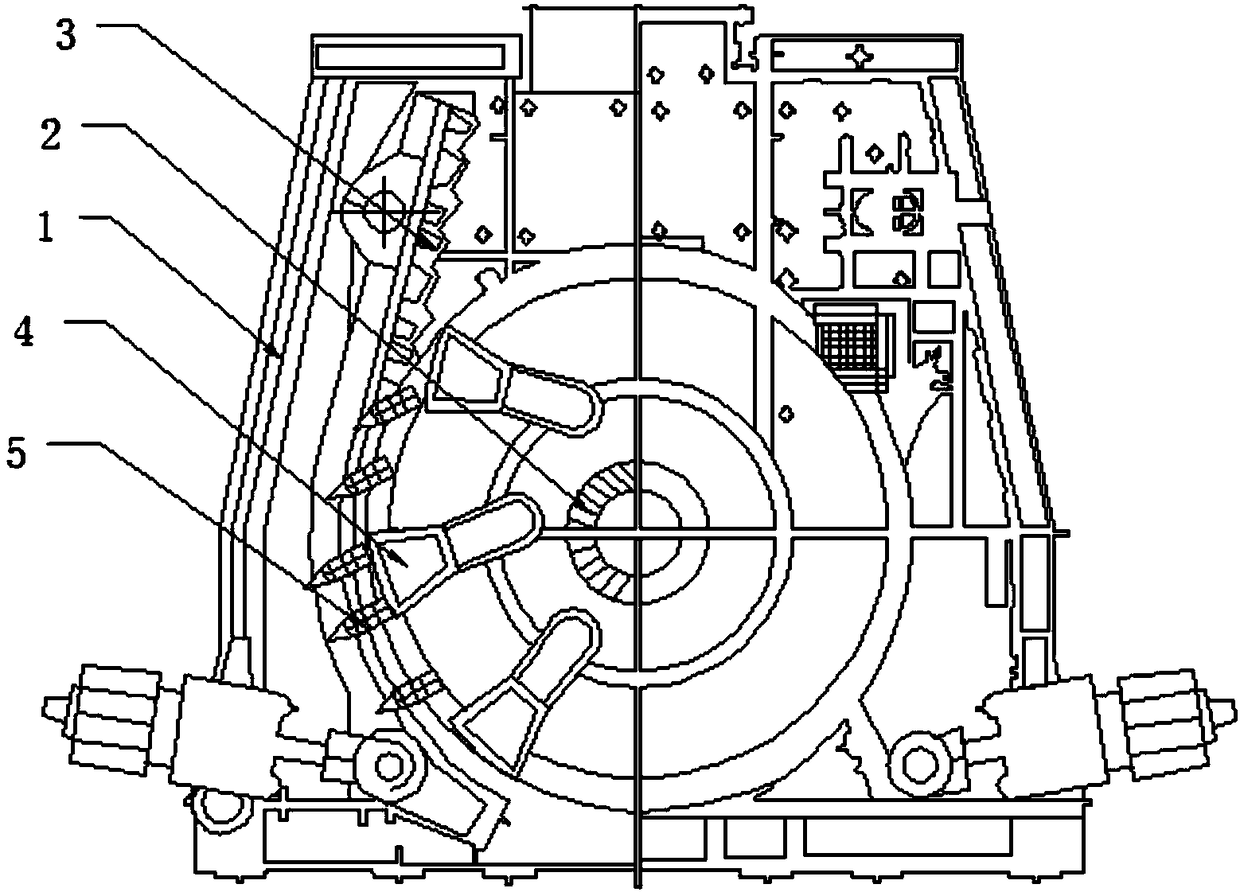

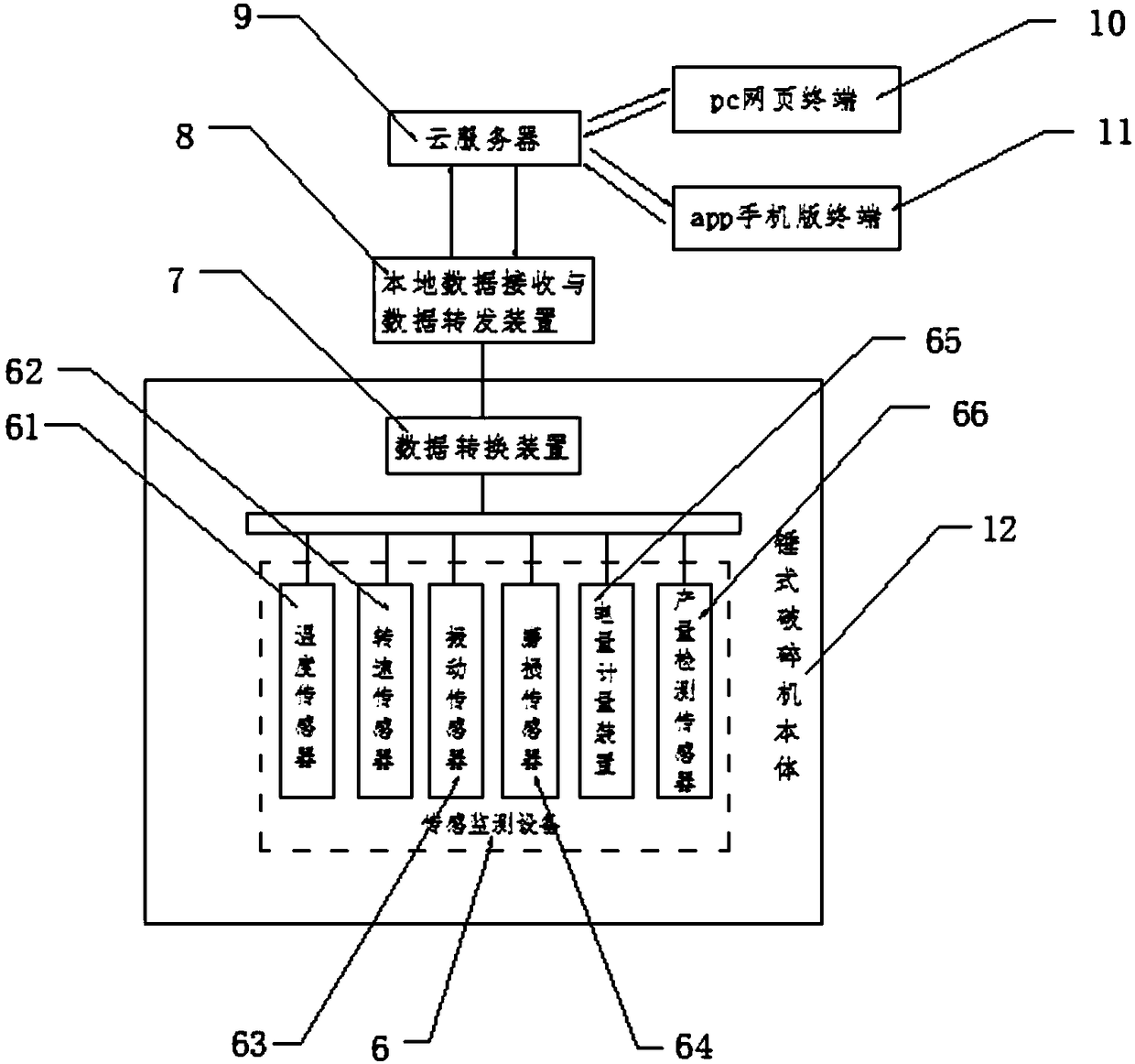

[0019] Example: such as Figure 1-2 As shown, the present invention provides an intelligent hammer crusher with a remote monitoring function, a frame 1 and a sensor detection device 6, a motor is installed on the frame 1, the motor is connected to an elastic coupling through a leather strap, and the elastic coupling Connect the rotor 2, the rotor 2 is installed on the shaft, the hammer 4 is installed on the rotor 2, the hammer 4 is connected to the crushing plate 3, the crushing plate 3 is set on the upper part of the grate screen 5, the hammer 4 is connected to the grate screen 5, The grate screen 5 is set at the lower part of the rotor 2; the motor provides the driving force for the elastic coupling to directly drive the rotor 2 to rotate, so that the hammer head 4 on the rotor 2 rotates at high speed in a radioactive manner, and can strike the materials entering the cavity of the crushing plate 3 , to form a primary crushing of the material; after the material is hit by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com