Intelligent monitoring system used for vibrating screen

An intelligent monitoring system, vibrating screen technology, applied in general control systems, control/adjustment systems, filter screens, etc., can solve the problems of difficult installation, easily disturbed data, fatigue vibration of vibration springs, etc. The effect of increasing transmission distance and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] An intelligent monitoring system for a vibrating screen, characterized in that: comprising

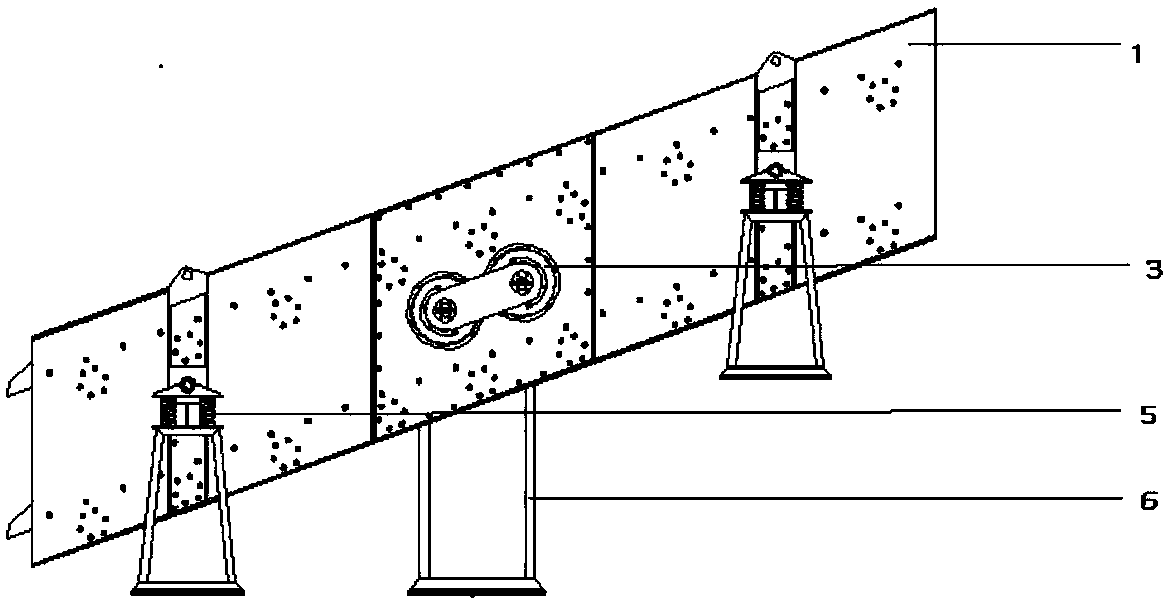

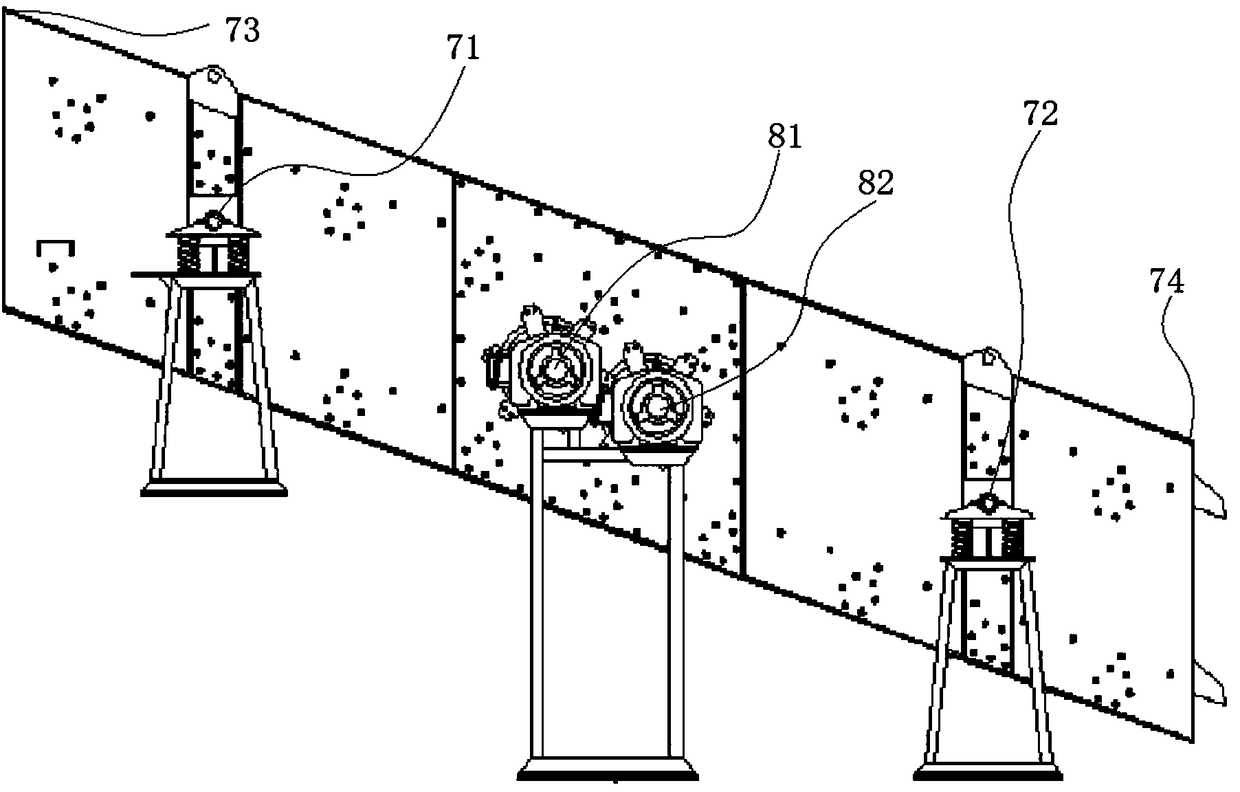

[0040] A number of vibration sensors are respectively arranged on the four corners of the screen box 1 of the vibrating screen and the damping spring 5 of the vibrating screen to monitor the vibration of the vibrating screen and the fatigue state of the damping spring 5; see image 3 , where the two vibration sensors 71, 72 are respectively arranged on the vibrating screen springs, the two vibration sensors 73 are respectively arranged on the two corners on the left side of the screen box; the two vibration sensors 74 are respectively arranged on the right side of the screen box 1 on the two corners of

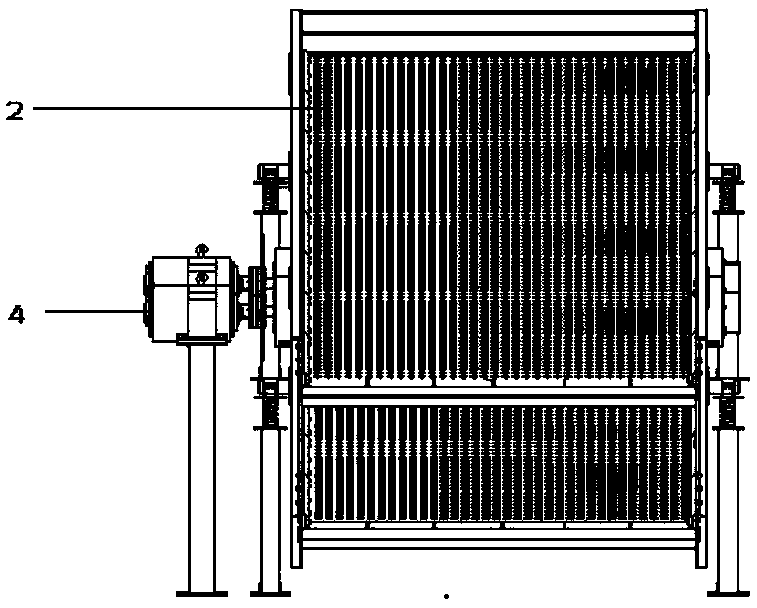

[0041] A number of temperature sensors are respectively arranged on the driving motor 4 of the vibrating screen to monitor the bearing temperature of the driving motor 4, and give an early warning before the temperature reaches a dangerous value, which can completely avoid the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com