Tread layer bonding device and tire forming machine

A technology of tire building machine and bonding device, which is applied in the field of tire manufacturing, and can solve problems such as low efficiency, high labor intensity of workers, and inability to preprocess

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] As used herein, the terms "comprises", "comprises" or any other variation thereof are intended to cover a non-exclusive inclusion of elements other than those listed and also other elements not expressly listed.

[0060] In this article, the orientation words such as front, back, up, down, left, right, top, and bottom are defined by the parts in the drawings and the positions of the parts between them, just to express The technical solutions are clear and convenient. It should be understood that the use of the location words should not limit the scope of protection claimed in this application.

[0061] Below in conjunction with specific embodiment and accompanying drawing, the present invention will be further described:

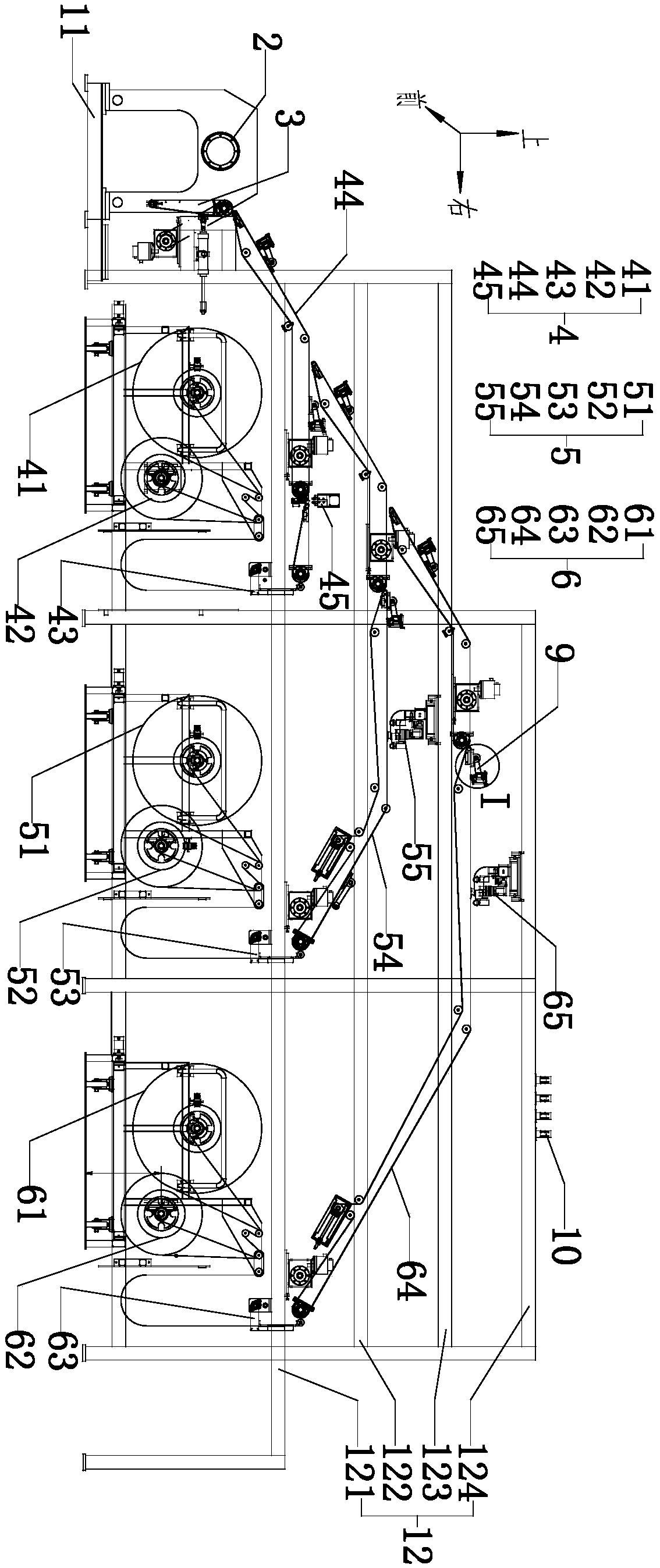

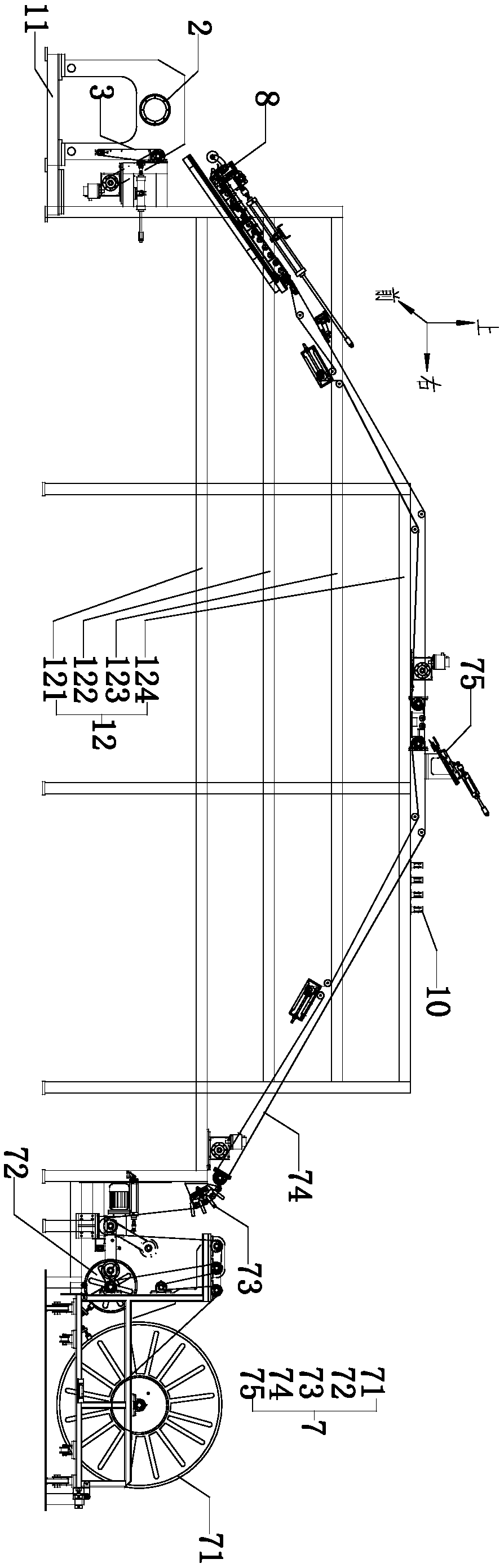

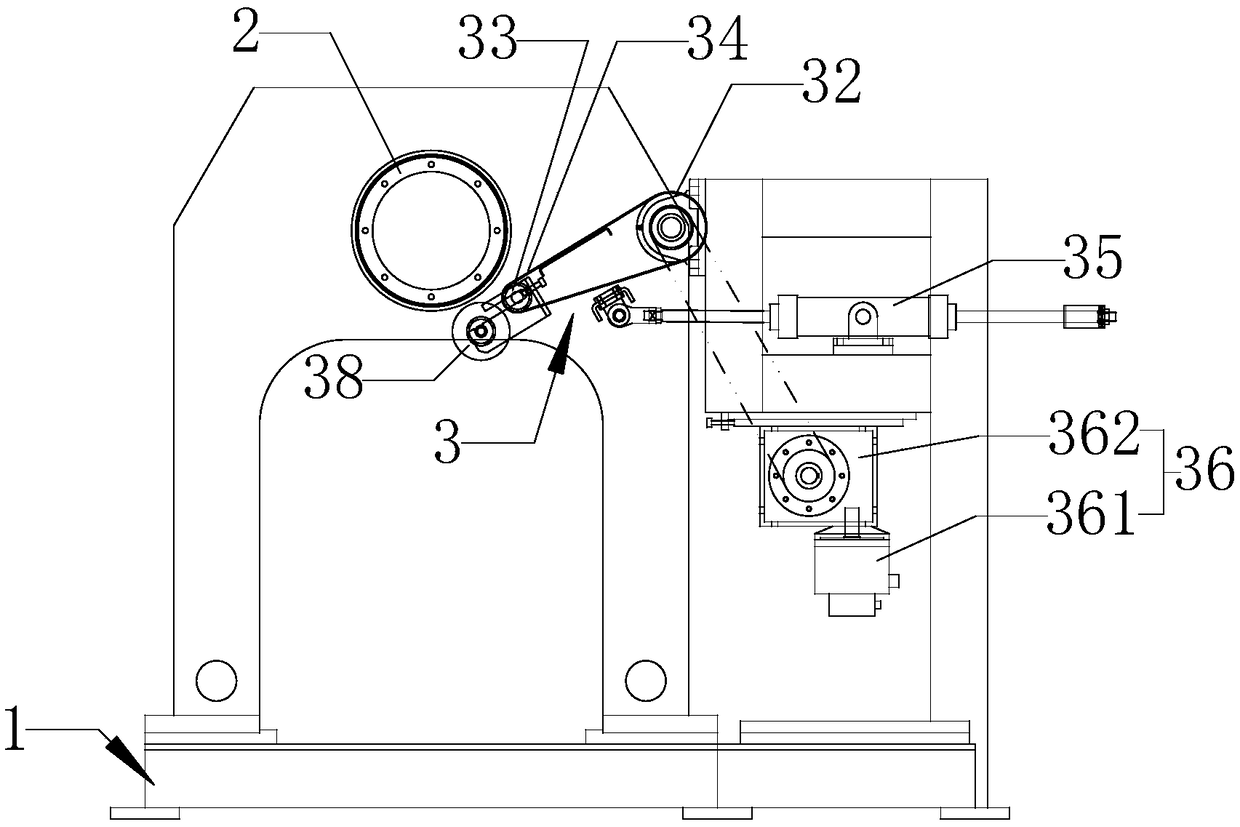

[0062] Such as figure 1 , 2 , 3, a tire building machine, comprising a frame 1, a building drum 2, a lower laminating device 3, an airtight layer conveying device 4, an inner ply conveying device 5, an outer ply conveying device 6, a tread layer T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com