Air conditioner bottom shell for overhead vehicle

A vehicle air conditioner and overhead technology, which is applied to vehicle components, air handling equipment, heating/cooling equipment, etc., can solve the problems of low strength, poor strength of the integrated LFT bottom shell, and small area of the integrated LFT bottom shell. , to achieve the effect of increasing the area, improving the load-bearing capacity and improving the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

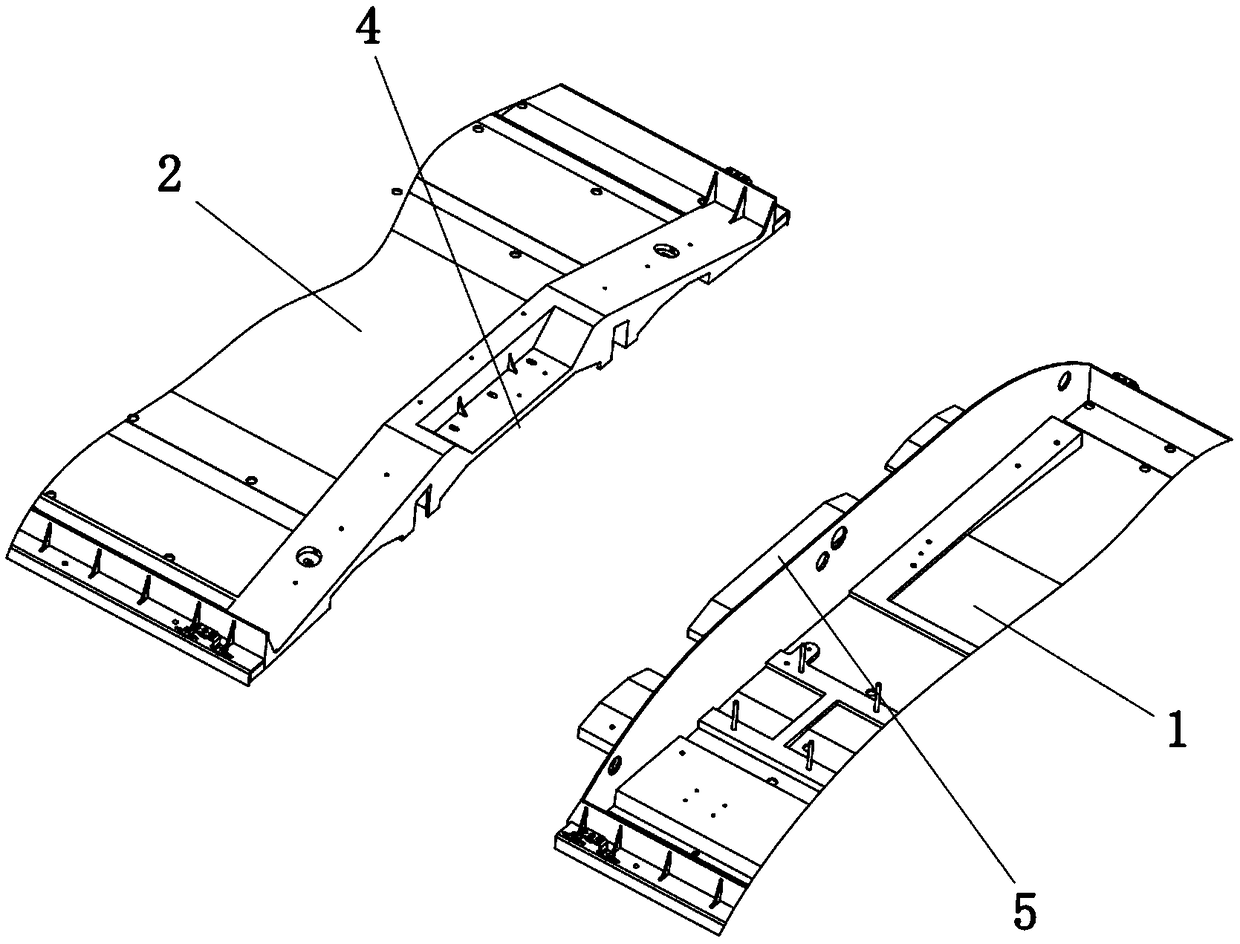

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific implementation manners described here are only used to explain the present invention, rather than to limit the present invention. In addition, it should be noted that, for the convenience of description, the accompanying drawings only show some but not all of the parts related to the present invention.

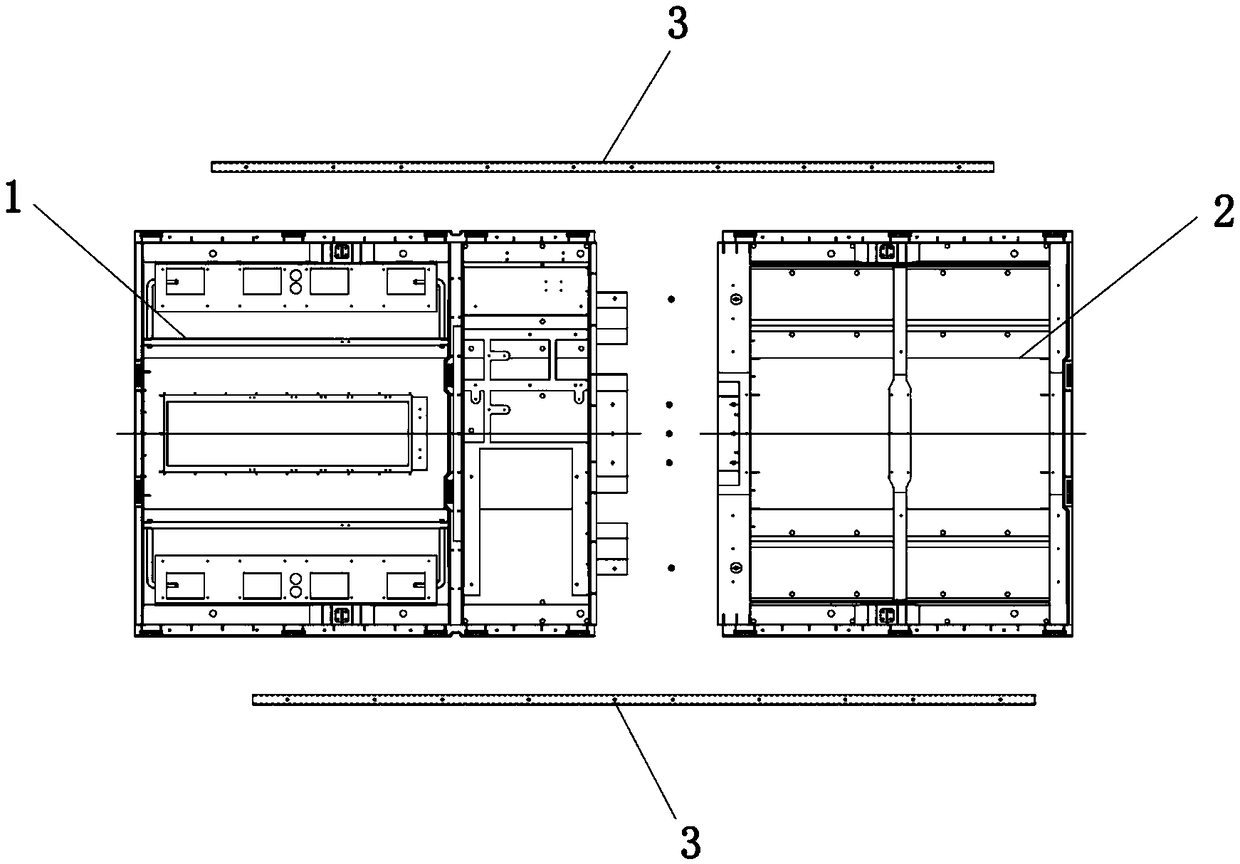

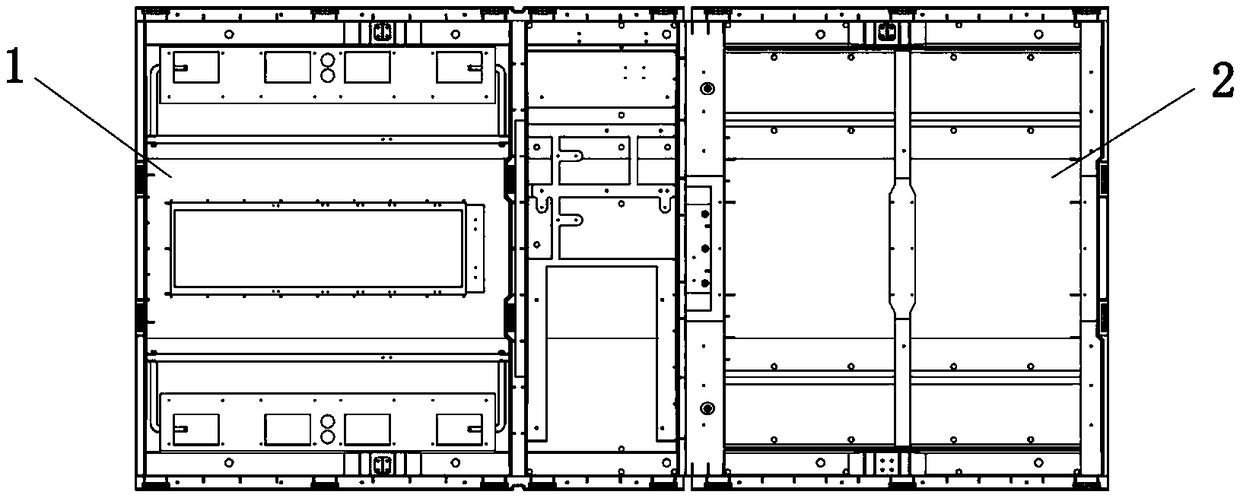

[0031] like figure 1 and figure 2 As shown, this embodiment provides a top-mounted vehicle air-conditioning bottom case, including a first bottom case 1, a second bottom case 2 and a structural beam 3, the first bottom case 1 is used to assemble an evaporator and a compressor, and the second bottom case The second bottom case 2 is used for assembling the condenser, the second bottom case 2 is detachably connected with the first bottom case 1 , and the structural beam 3 is arranged thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com