Aircraft cap rotation hinge device

A technology of rotating hinges and flaps, which is applied to aircraft power units, aircraft power unit components, and aircraft accessories. It can solve the problems of affecting local aerodynamic performance and poor sealing performance, and achieves the problem of sealing performance and occupying internal space. contradictory effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

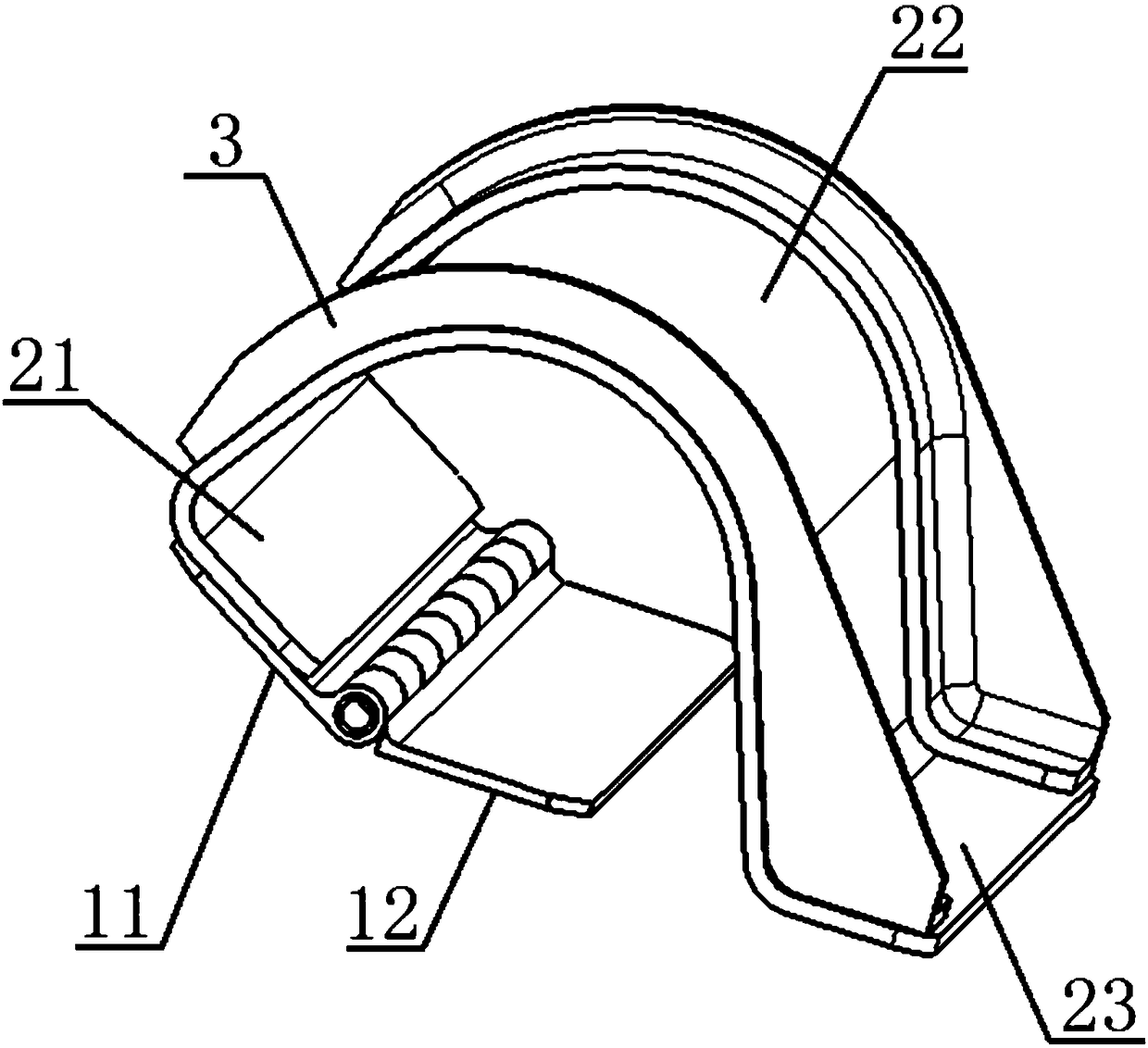

[0018] The invention provides a rotary hinge device for an aircraft hatch such as figure 1 As shown, it can be used in the connecting part of the quick-release maintenance cover, which includes hinge 1 and hinge skin 2. Hinge 1 is preferably made of 2A12-T4-XC01-6 hard aluminum alloy material, and hinge skin 2 is preferably Made of 2A12-O aluminum alloy material, hinge 1 includes left hinge piece 11 and right hinge piece 12, hinge skin 2 is integrally formed structure, one end of which is the first skin section 21, and the other end is the third cover Leather segment 23, the middle of the first skin segment 21 and the third skin segment 23 is the second skin segment 22;

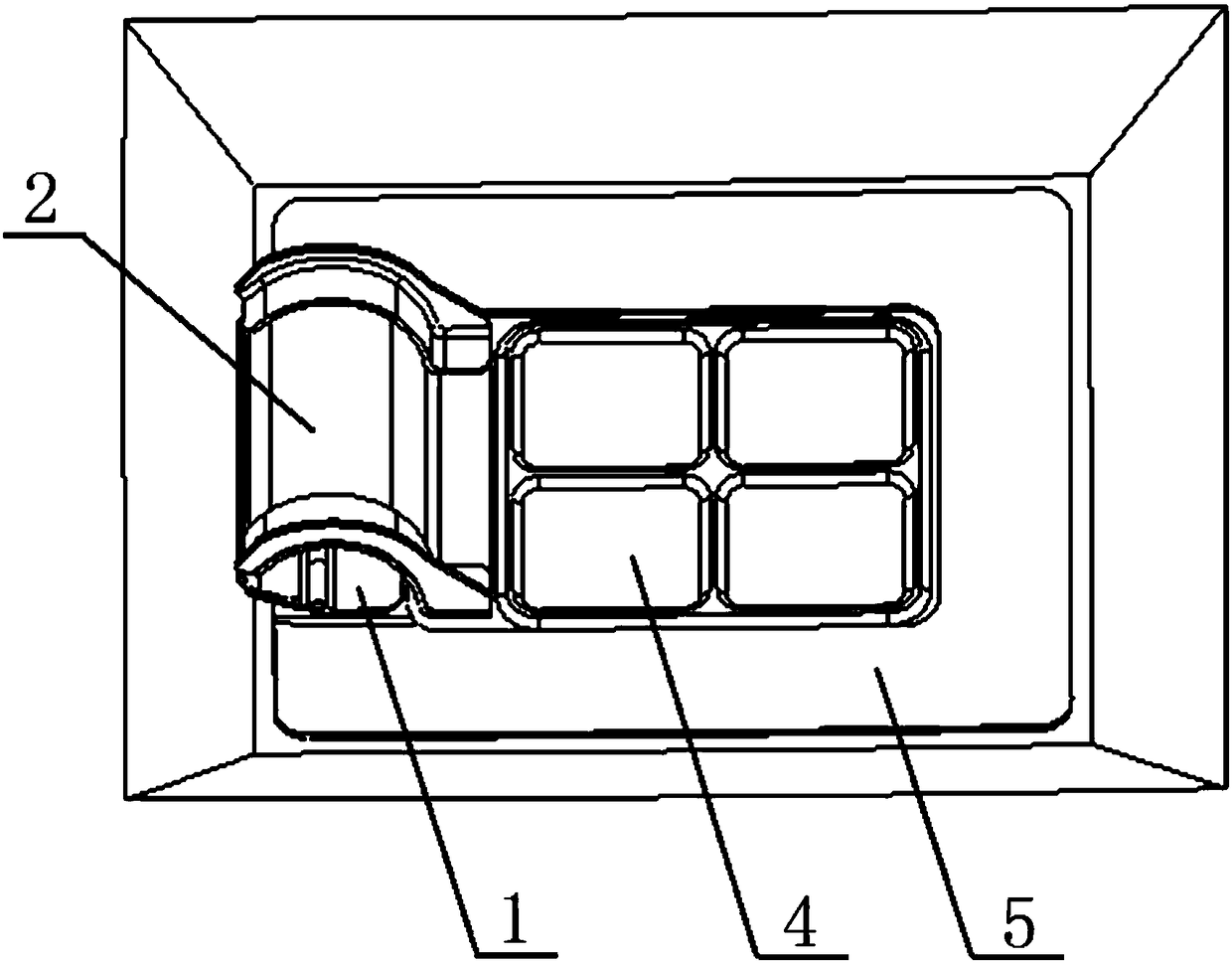

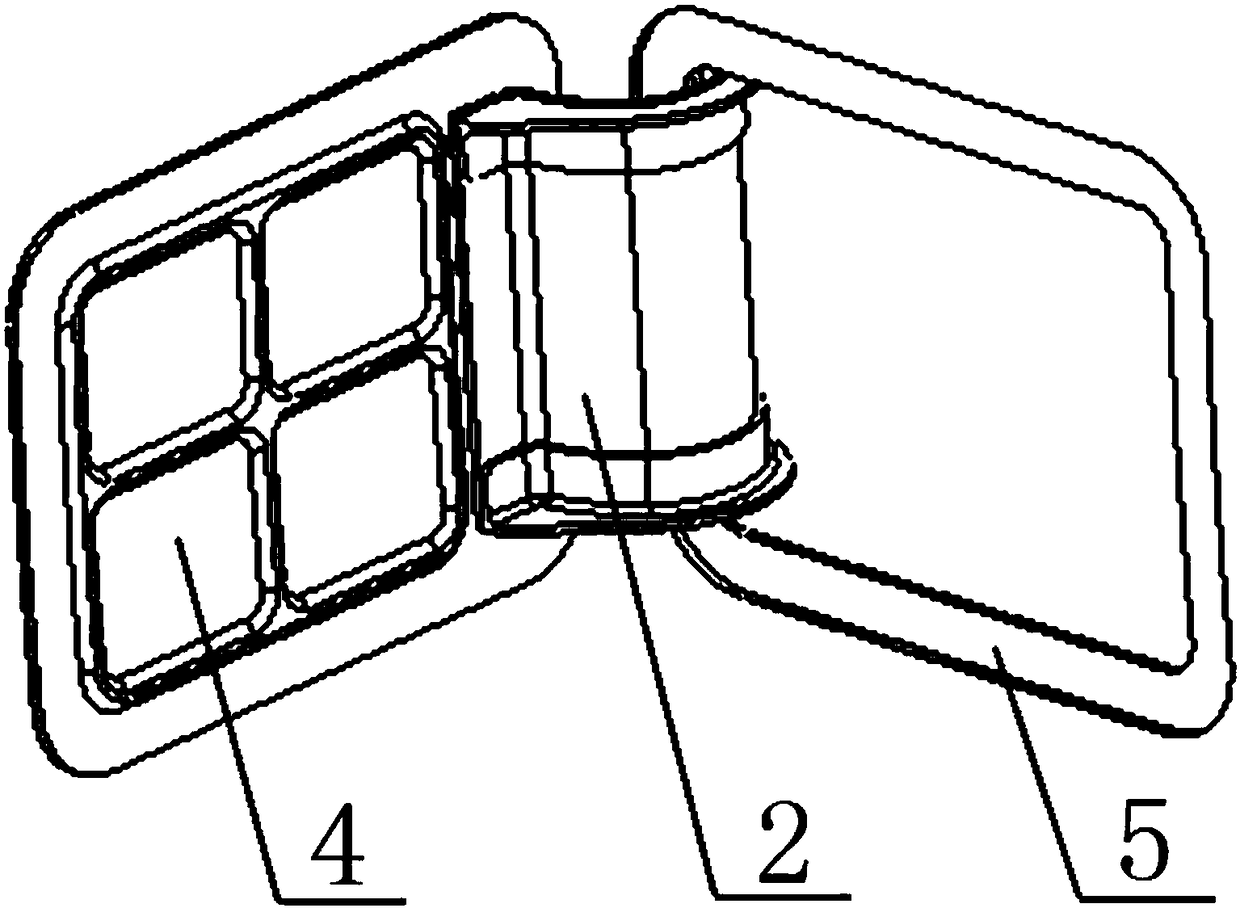

[0019] Such as figure 2 As shown, the right hinge piece 12 of the hinge 1 is fixed to the frame 5 of the fuselage, and the first skin segment 21 is flat and fixed to the left hinge piece 11 of the hinge 1, which is preferably fixed by riveting , the third skin section 23 is flat and fixed with the mouth co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com