Integrated heat exchanger

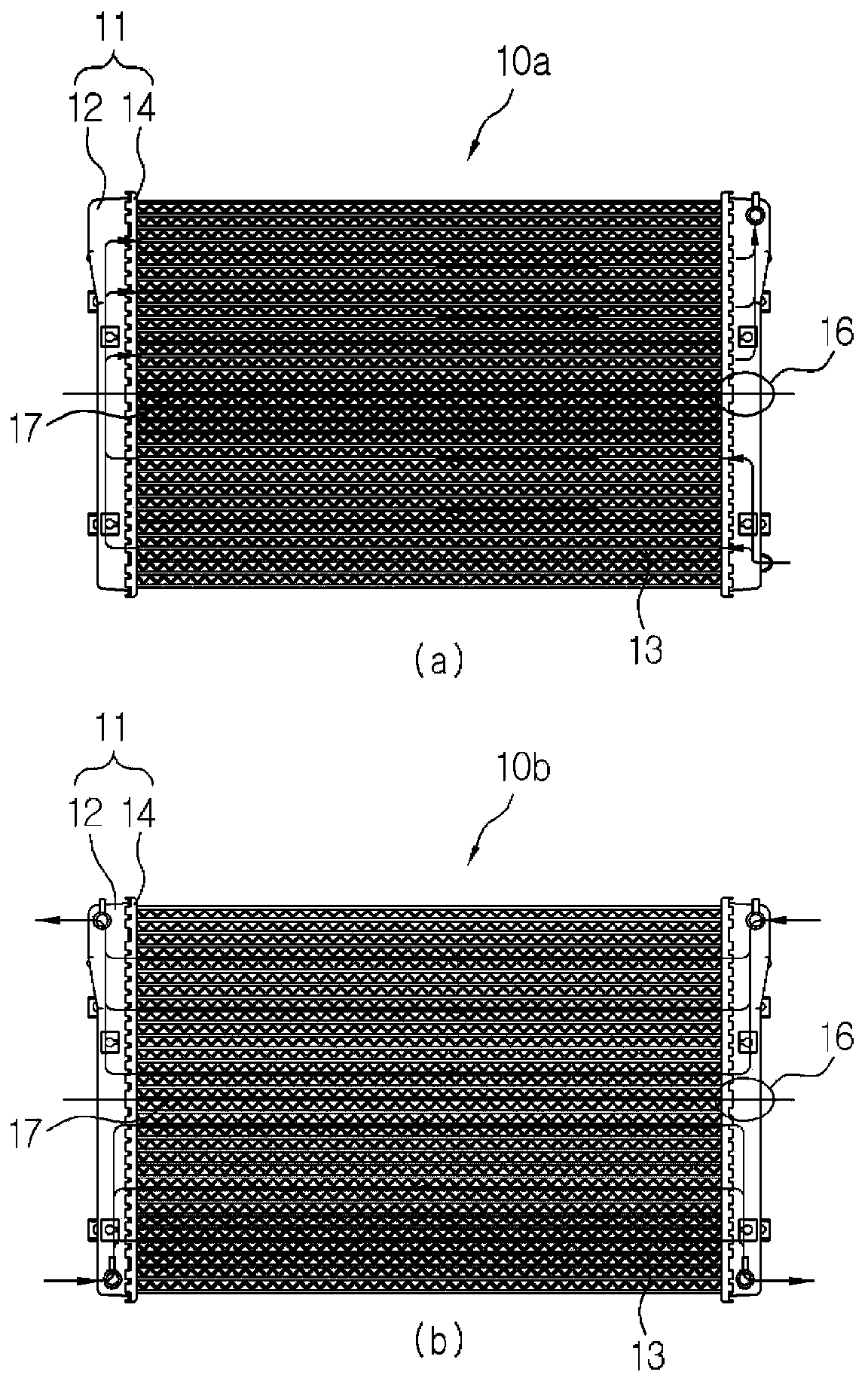

A heat exchanger, an integrated technology, applied in the direction of heat exchange equipment, heat exchanger type, heat exchanger shell, etc., can solve the problems of reducing assembleability, deformation, separation of gasket 15, etc., and achieves the improvement of assembleability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

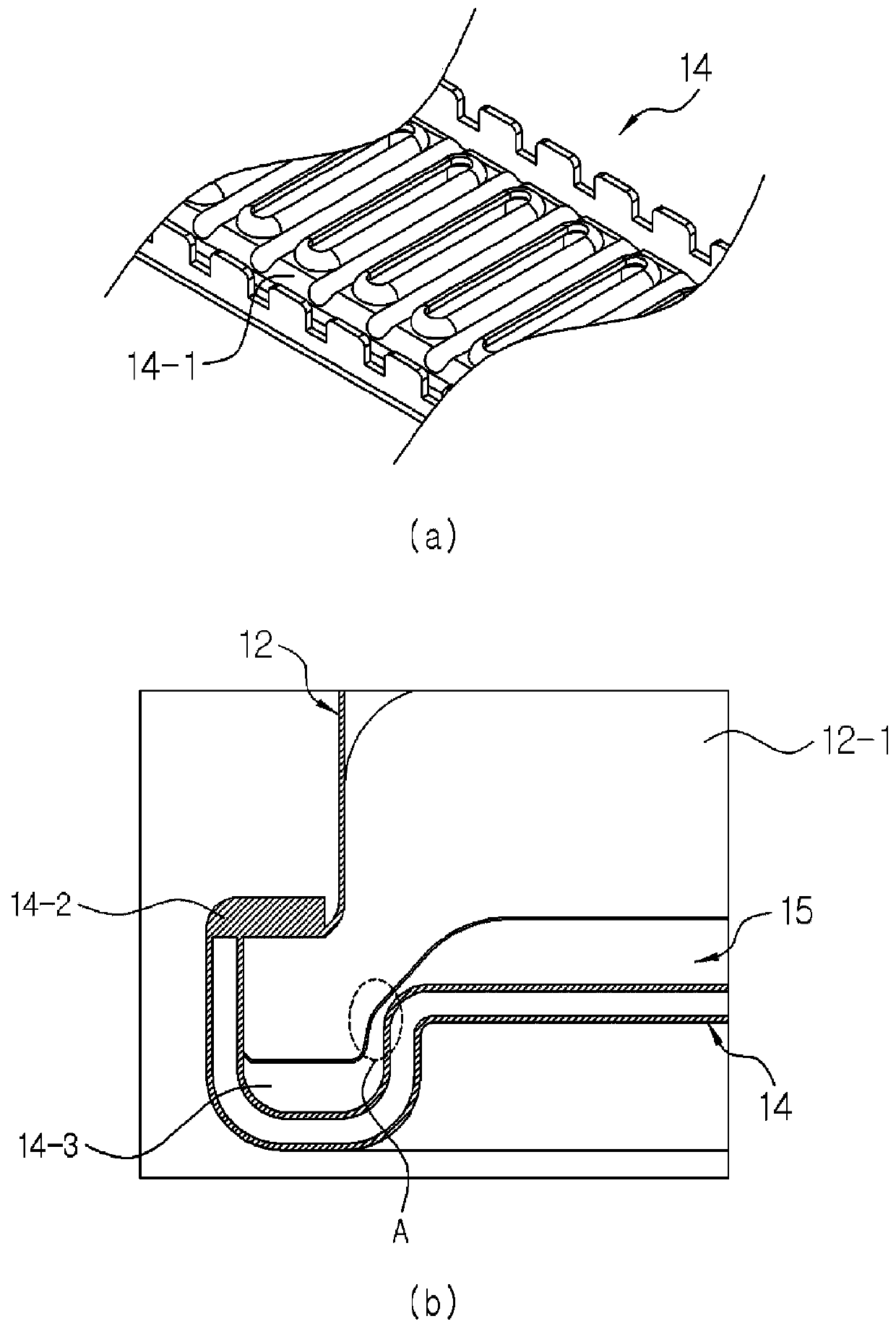

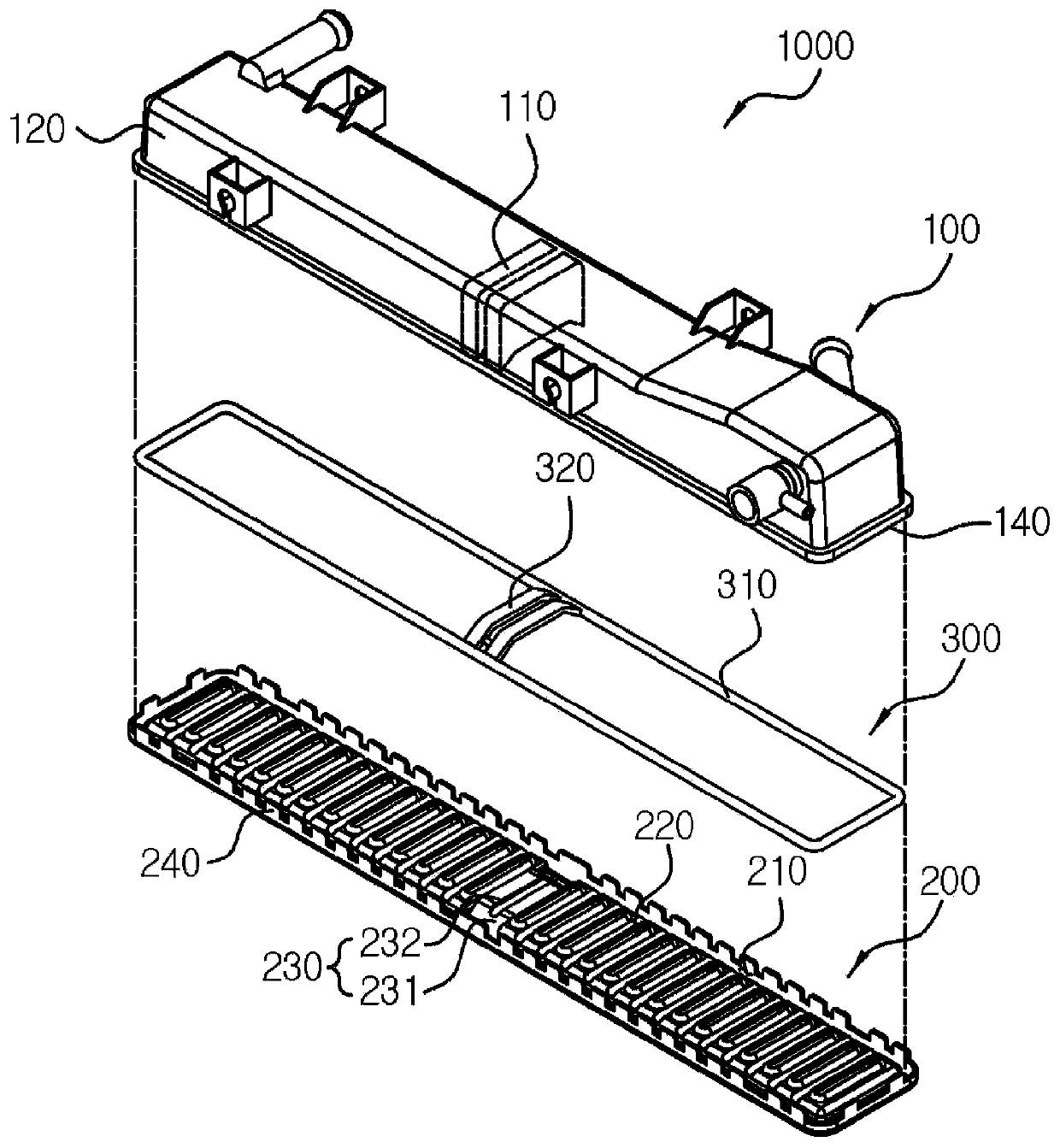

[0026] In the integrated heat exchanger of the present invention in which a header tank is attached to both ends of a plurality of heat exchange tubes, the header tank includes: a tank 100 to which the first heat exchange medium and the second heat exchange medium are supplied; tube 200, the header 200 is connected to the heat exchange tube; and a gasket 300, which is inserted between the tank 100 and the header 200, wherein a tank baffle 110 is installed in the tank to separate the first heat exchange medium and the second heat exchange medium medium, the gasket 300 includes a baffle seal portion 320 disposed at a portion in contact with the tank baffle 110, the header 200 includes a support surface 230 disposed at a portion in contact with the baffle seal portion 320, and the support surface 230 includes a height The inclined surface 231 decreases towards the outside of the header 200 .

[0027] In addition, the support surface 230 has a flat seating surface 232 connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com