A kind of flexible fiber composite sheet for anti-seepage and reinforcement of concrete dam and preparation method thereof

A technology for concrete dams and composite sheets, applied in chemical instruments and methods, synthetic resin layered products, coatings, etc., can solve problems such as engineering danger, cost waste, reinforcement failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

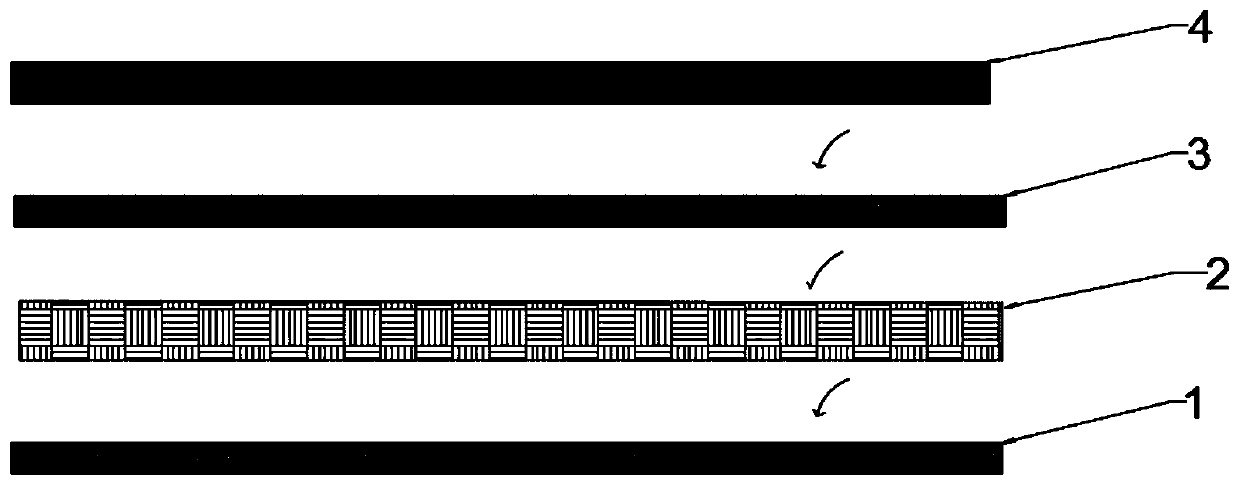

[0021] See Figure 1-2 , a flexible carbon fiber composite sheet for anti-seepage and reinforcement of concrete dams, its composition system is: flexible impregnated resin layers 1 and 3 for impregnation bonding, water resistance and anti-seepage, and carbon fiber cloth layers for load sharing 2 and the plastic plate layer 4, the specific structure is the first flexible impregnated resin layer 1, the carbon fiber cloth layer 2, the second flexible impregnated resin layer 3, and the plastic plate leveling layer 4 connected in sequence;

[0022] In order to achieve the reinforcement effect of general engineering, the first and second flexible impregnated resin layers 1 and 3 are made of SK series single-component polyurea resin produced by Beijing Zhongshui Kehaili Engineering Technology Co., Ltd. The specific properties are: Bond strength is 3.0MPa (test standard is CECS146-2003), tensile strength is 16MPa (test standard is GB / T 2568-1995), elongation is 350% (test standard is ...

Embodiment 2

[0053] The polyurea resin used in Example 2 and Example 1 is the same brand; the carbon fiber cloth layer 2 adopts the unidirectional carbon fiber cloth produced by Hummer Company, the model is HM-30, and the specific specification is: 300g / cm 2 , the tensile strength is 3700MPa, and the elongation is 2.0%. (Test standard: the test standard is CECS146-2003). The plastic plate leveling layer 4 adopts another model of Hengchuang brand GB plastic plate with a thickness of 0.60mm;

[0054] The specifications of the finally prepared composite sheet are: the sum of the thicknesses of the first flexible impregnated resin layer 1, the carbon fiber cloth layer 2 and the second flexible impregnated resin layer 3 is 5.00mm, and the plastic plate leveling layer 4 has a thickness of 0.60mm and an overall thickness of 5.60mm.

[0055] Effect test

[0056] Five groups of 300mm×300mm flexible carbon fiber composite panels for concrete reinforcement were prepared by the above preparation me...

Embodiment 3

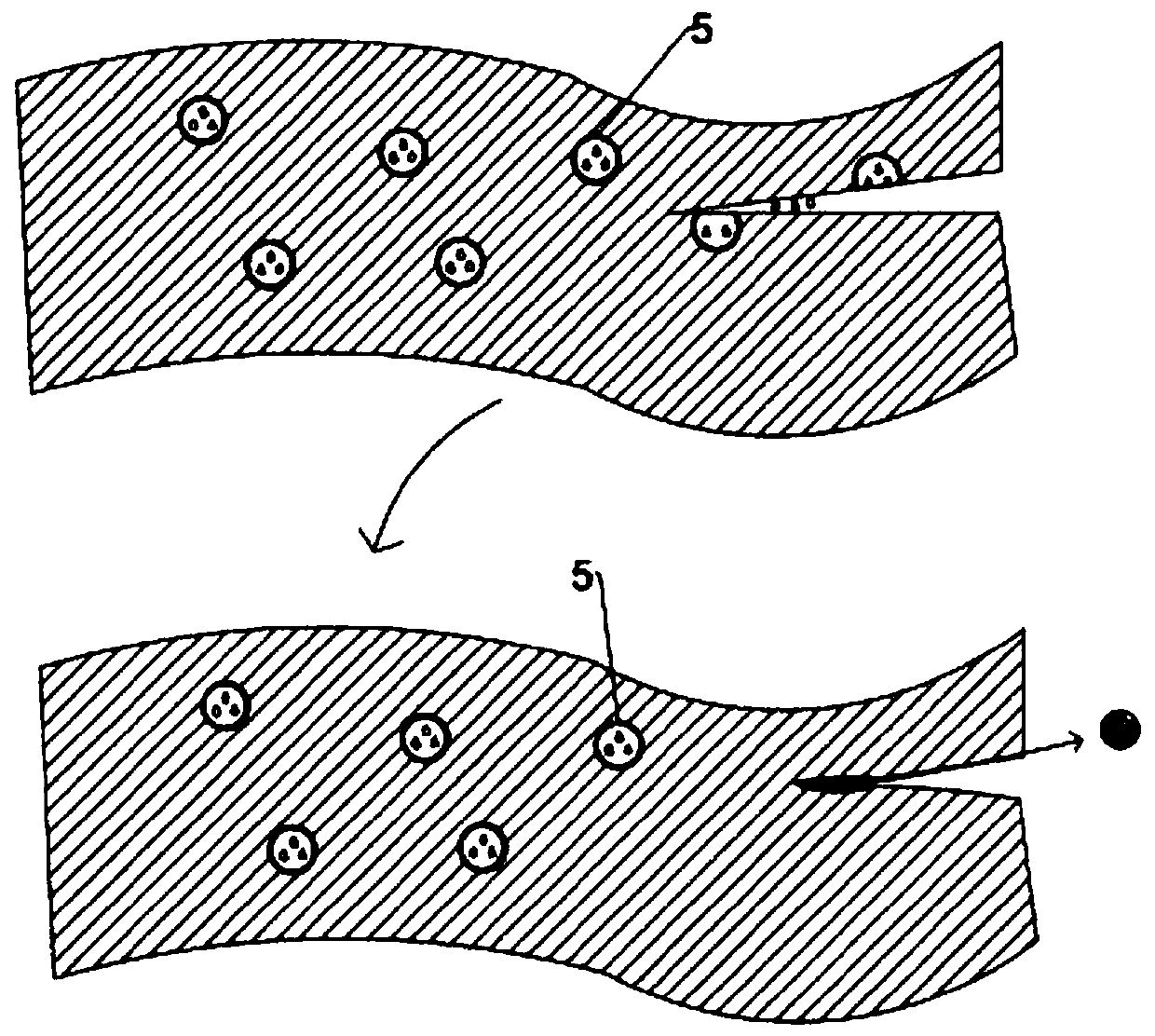

[0065] The difference between Example 3 and Example 1 is that a self-healing material 5 is added to the impregnated resin layer, specifically, polyurethane / silica-coated hexamethylene diisocyanate [HDI@(PU / SiO 2 )] hybrid microcapsules, the microcapsules are added into the polyurea resin by stirring, and the addition amount is 10wt%.

[0066] Such as image 3 , the principle of self-healing is that the isocyanate repairing agent is coated in microcapsules and then embedded in the matrix. When the matrix resin cracks due to excessive stress, the microcapsules rupture and the isocyanate repairing agent flows out and penetrates into the cracks. Moisture in the air undergoes a moisture curing reaction to achieve self-repair. Since this repair mechanism does not require additional curing agents, it is easy to use and is especially suitable for dam or underwater repair.

[0067] The HDI@(PU / SiO 2 ) The concrete preparation method of microcapsule is:

[0068] (1) Weigh 1.5 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com