Continuous variable-stiffness shear key type steel-concrete joint section

A technology of concrete bonding and shear keys, which is applied to structural elements, elongated structural members for load-bearing, building components, etc., can solve the problem of uneven load distribution of shear keys and achieve improved load distribution, The effect of reducing the load and increasing the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

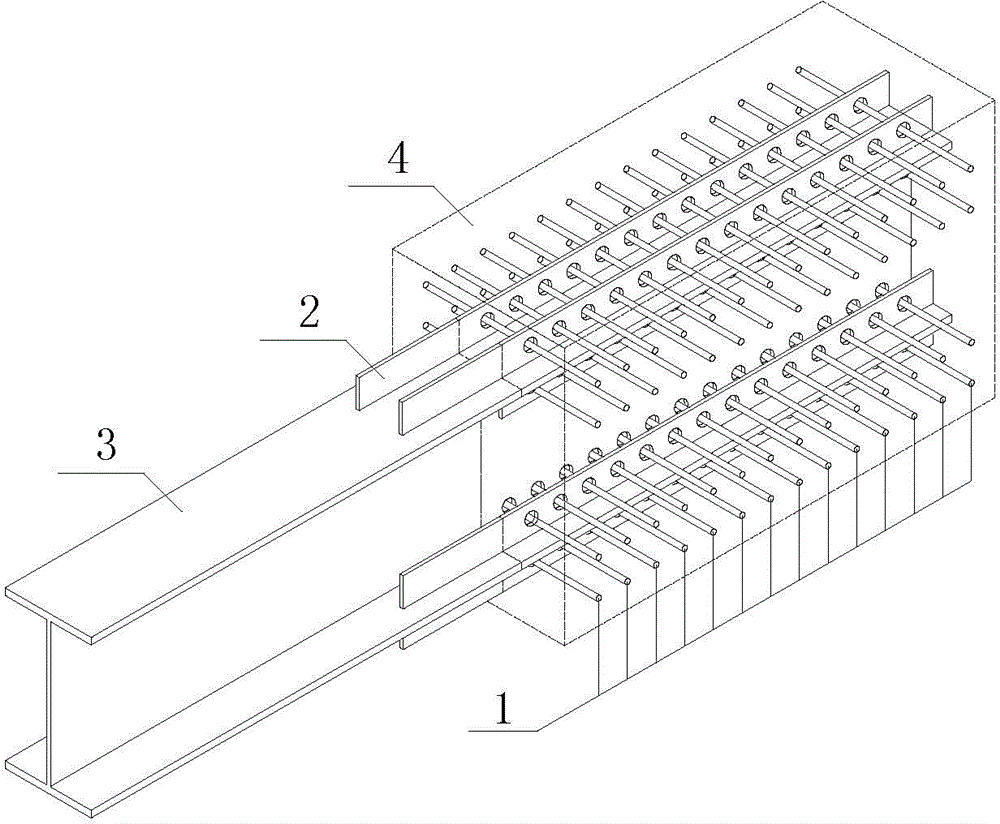

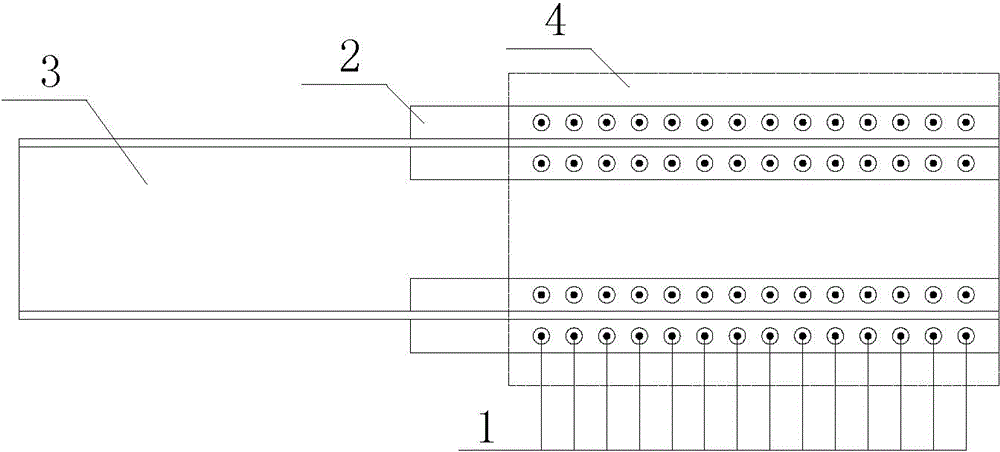

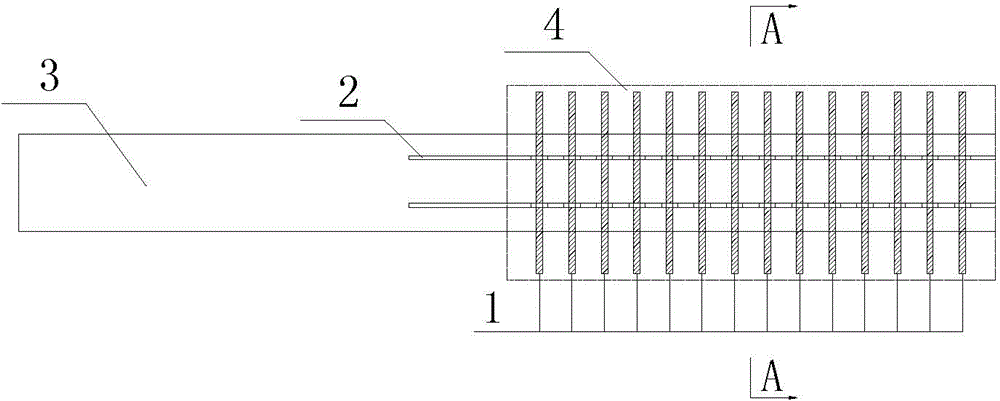

[0025] In the following, the continuous variable stiffness shear key type steel-concrete joint section of the present invention will be further described with reference to the accompanying drawings.

[0026] like figure 1 As shown, the steel-concrete joint structure includes: steel beam 3, concrete beam 4, perforated steel plate 2 and ribbed through steel bar 1; The upper and lower surfaces of the lower flange; the web of the steel beam 3 is provided with a circular hole corresponding to the perforated steel plate 2; the ribbed through steel bar 1 passes through the center of the circular hole on the perforated steel plate 2 and the web of the steel beam 3; The concrete beam 4 is poured on the periphery of the steel beam 3 and wraps the perforated steel plate and the ribbed through steel bar. The shear force between the steel beam and the concrete beam is resisted by the concrete tenon and ribbed penetration reinforcement in the circular hole of the perforated steel plate.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com