Automatic clamping telescopic winding device suitable for packing straps

A winding device and automatic clamping technology, applied in the directions of transportation and packaging, coiling strips, thin material handling, etc., can solve the problems of decreased production efficiency, machine failure, easy loosening and falling off of nuts, etc., and achieve improved structural form, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with specific examples.

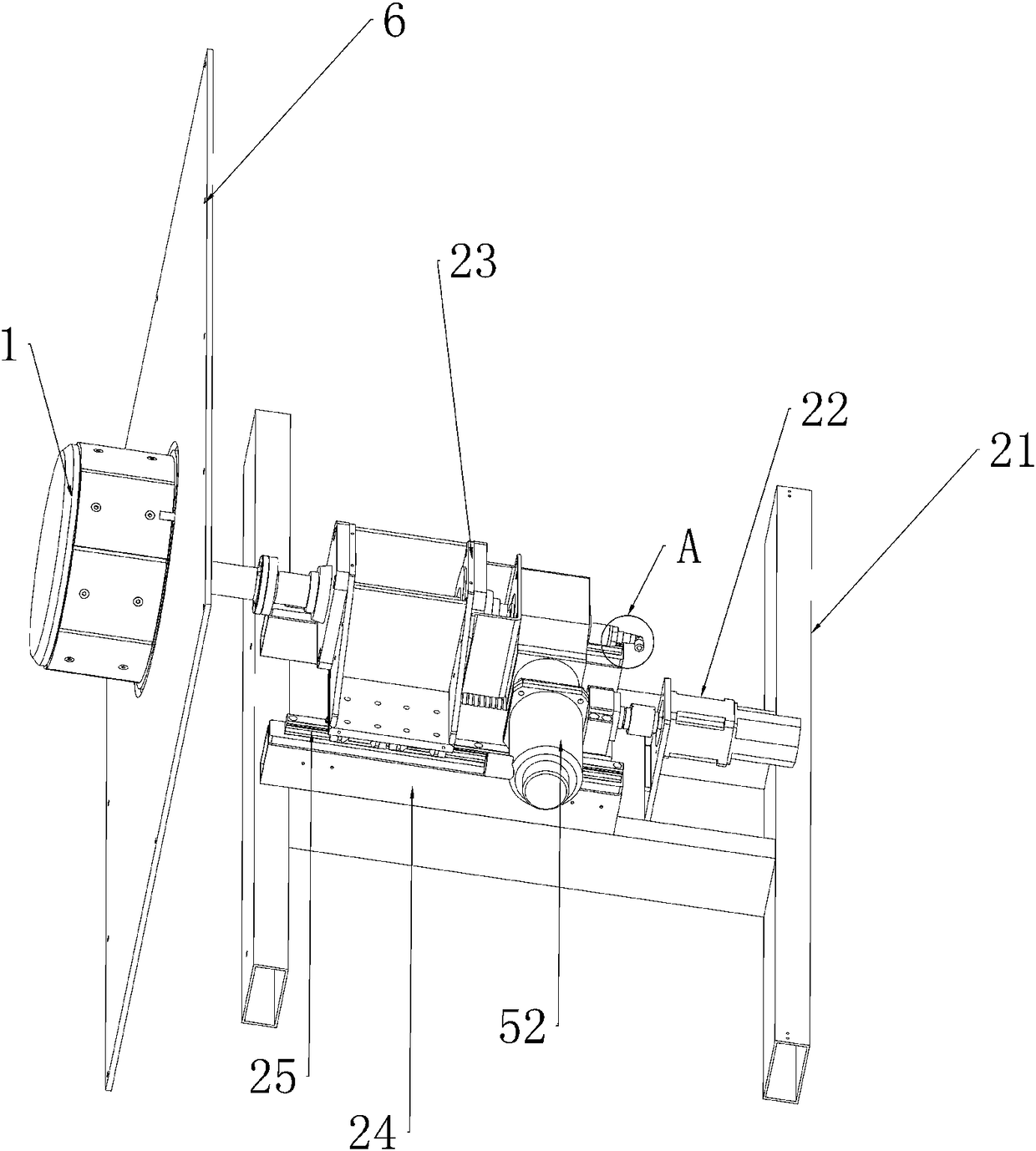

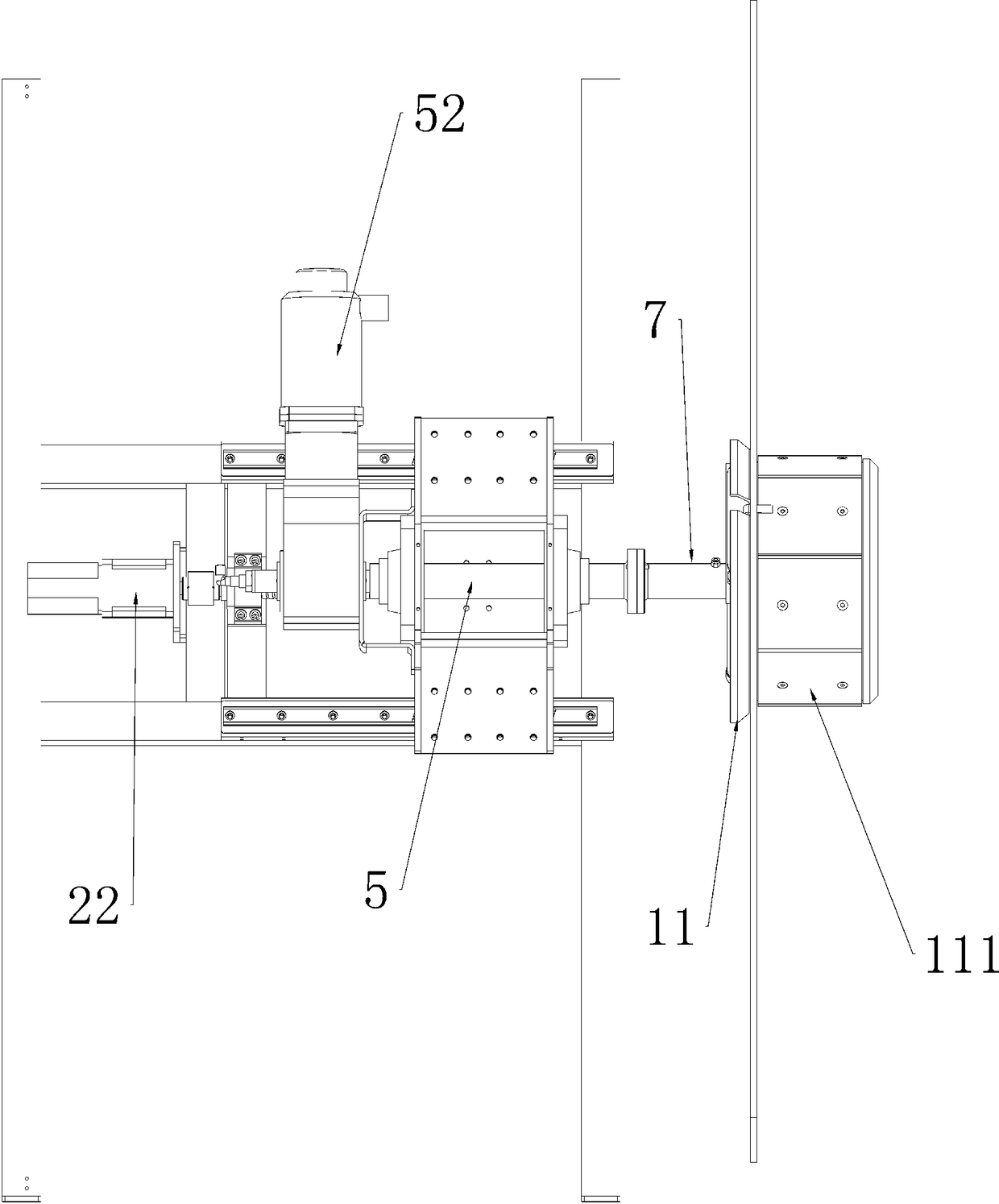

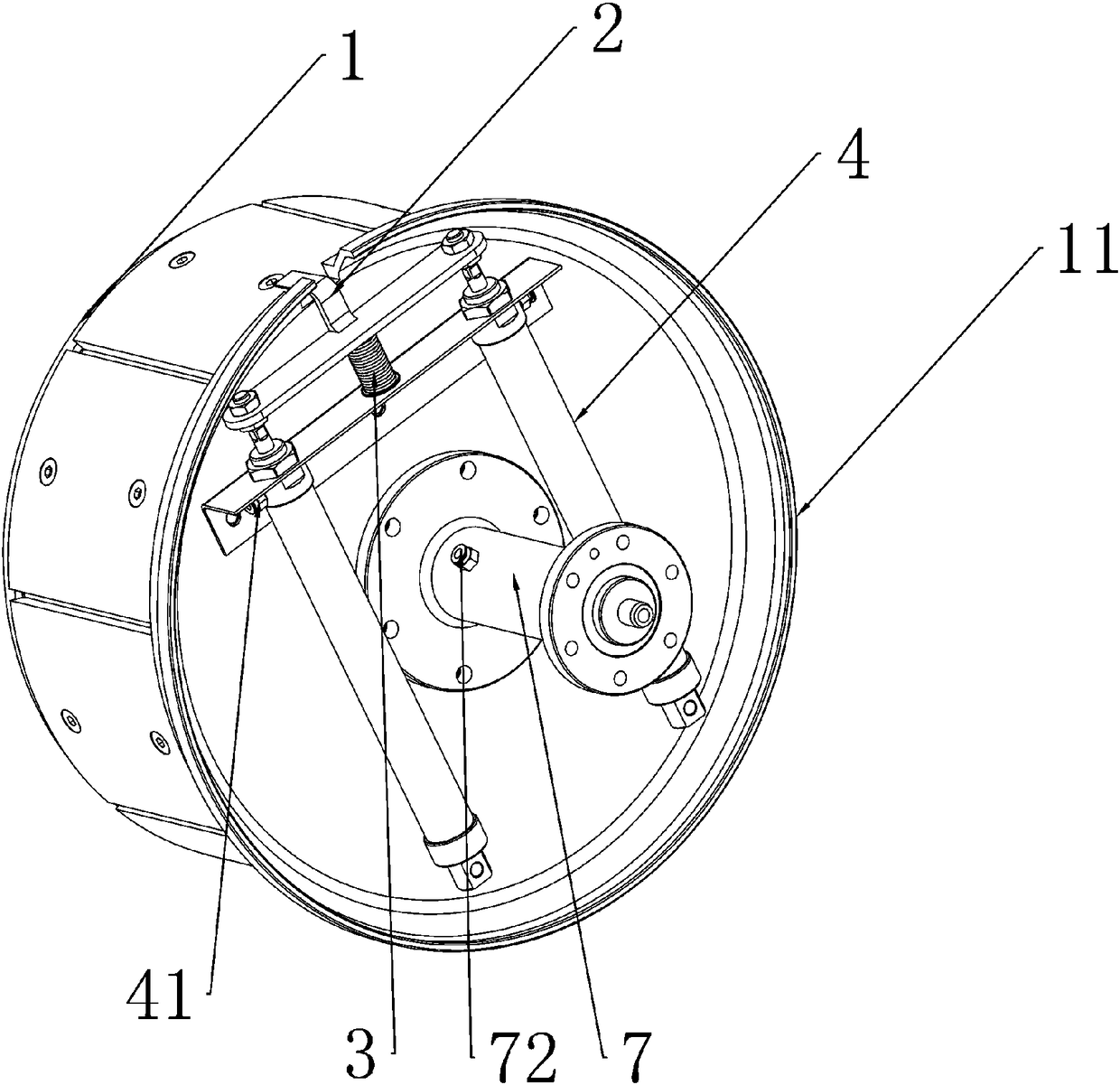

[0020] See attached Figure 1-4 As shown, in this embodiment, an automatic clamping telescopic rewinding device suitable for packing belts includes an air-expanding rewinding shaft 1, a fixed unloading plate 6, an axial drive assembly, and an air-expanding rewinding shaft 1 The tape pressing sheet 2 on the periphery of the peripheral surface drives the air-expanding rewinding shaft 1 to advance axially through the axial drive assembly and automatically clamps and cooperates with the tape pressing sheet 2 to complete the winding process. The tape pressing sheet 2 is automatically released, and the shaft Drive the air expansion reel 1 to the drive assembly to reset and cooperate with the fixed unloading plate 6 to complete the unwinding process; Peripheral surface of the reel 1 (there is a certain gap between the tape pressing piece 2 and the air-inflated reel 1 surrounding sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com