110KV tensile rod composite insulator outgoing line hanging ladder

A composite insulator and tensile rod technology, applied in ladders, buildings, building structures, etc., can solve the problems of inconvenient portability, handling and storage, lack of disassembly, folding functions, and lack of length adjustment. The effect of carrying, handling and storage, easy to step on and pass through, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

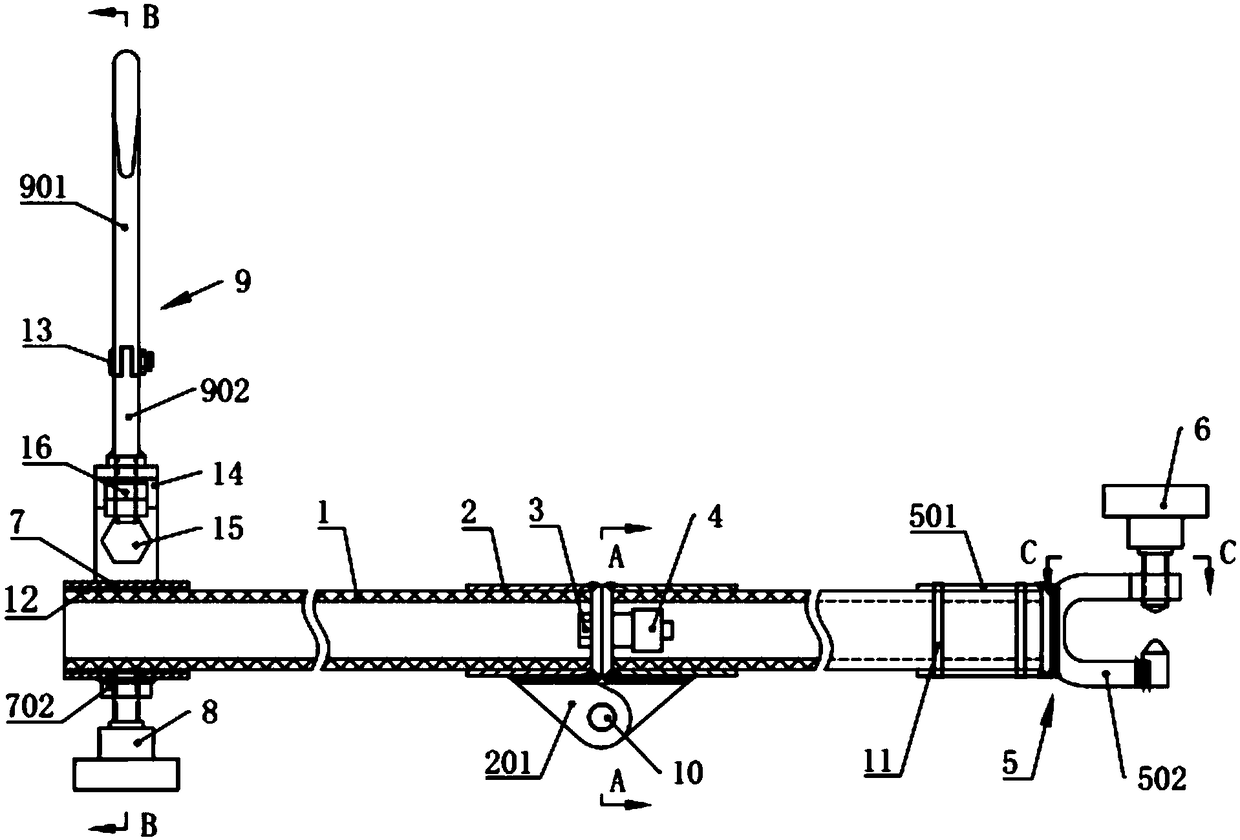

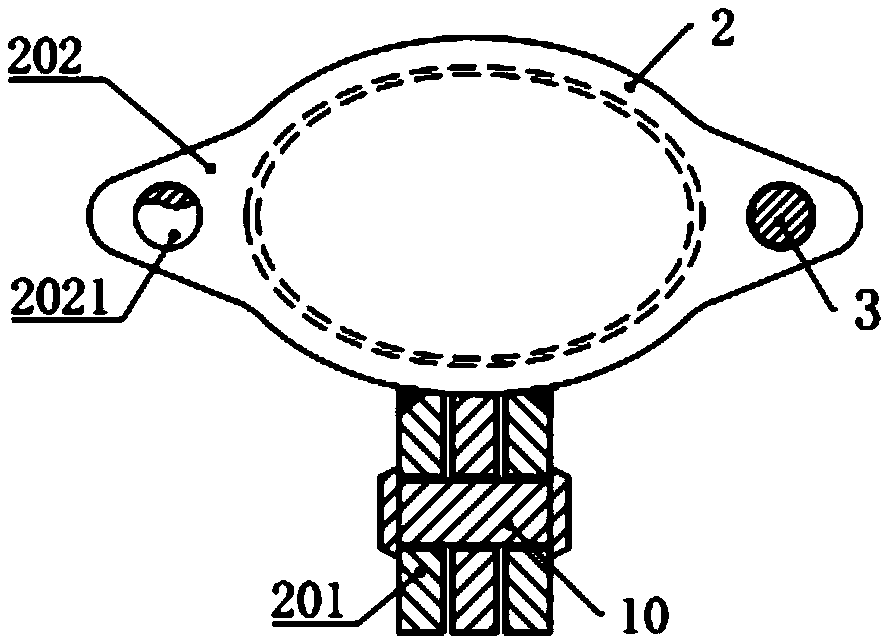

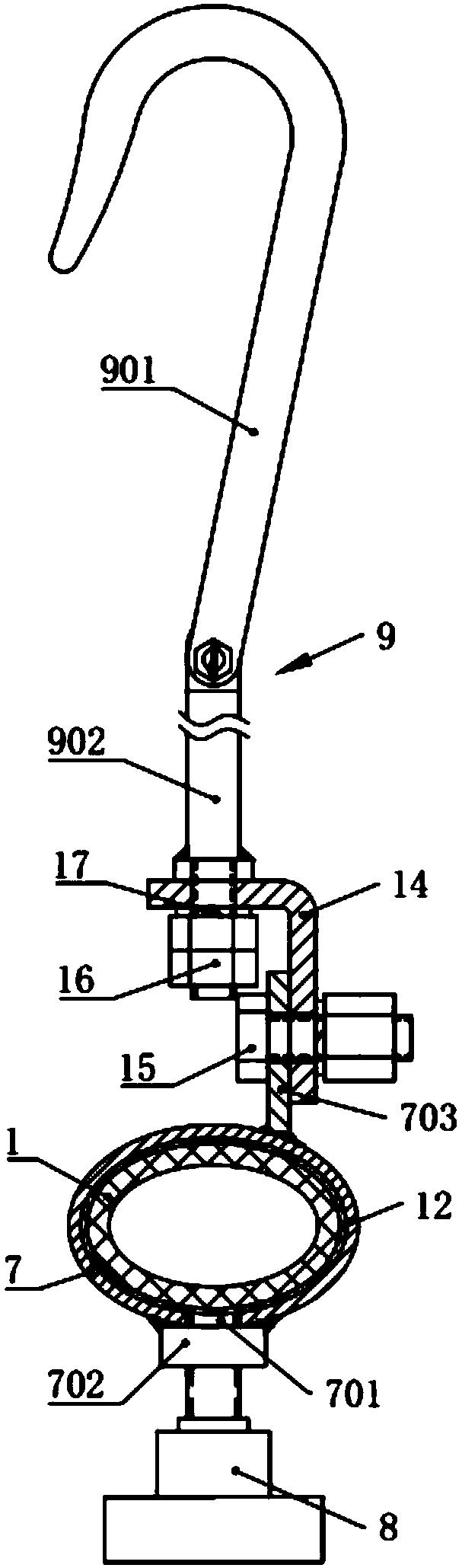

[0042] Such as Figure 1 to Figure 4 As shown, this embodiment provides a 110KV tension rod composite insulator outlet hanging ladder, including an insulating rod 1 with an elliptical radial section, two insulating rods 1 are provided, and one end of the two insulating rods 1 is fixedly installed. The elliptical sleeve 2, the bottom of the two elliptical sleeves 2 are hingedly connected, and the two sides are fixedly connected by the connecting bolt 3 and the knurled nut 4 respectively, and the knurled nut 4 provided can be directly screwed and fastened when in use, which is convenient to use; In the embodiment, the elliptical sleeve 2 is fitted on the end of the insulating rod 1 and fixed by a rivet 11 .

[0043] The insulating rod 1 has an elliptical structure in radial cross-section, has high structural strength, and is convenient for maintenance personnel to step on and pass through, and has good passability for personnel.

[0044] In order to make the hanging ladder have...

Embodiment 2

[0061] The structure of this embodiment is the same as that of Embodiment 1, the difference is that the structure of the connecting ear 202 of one of the oval sleeves 2 is as follows: Figure 7 As shown, the connecting ear 202 of the elliptical sleeve 2 is provided with a clamping notch 2022, and the opening of the clamping notch 2022 faces upward, and the connecting bolt 3 is fixedly installed on the connecting ear 202 of another elliptical sleeve 2. When in use, the two insulated The rods 1 are docked, the screw of the connecting bolt 3 is snapped into the snap-in gap 2022 of the corresponding connecting ear 202, and the knurled nut 4 is tightened to realize the positioning connection. Compared with the connection method of the two insulating rods 1 in Embodiment 1, folding and When connecting, there is no need to disassemble the connecting bolt 3 and the knurled nut 4, which is more convenient to use and more convenient to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com