Sliding bearing raise-boring machine inserted tooth hob capable of being disassembled quickly

A technology for sliding bearings and raise drilling rigs, which is applied to drill bits, earthwork drilling, drilling equipment, etc. It can solve the problems of limited material selection, complicated process operation, and high price, so as to achieve long service life, reduce manufacturing costs, and improve mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

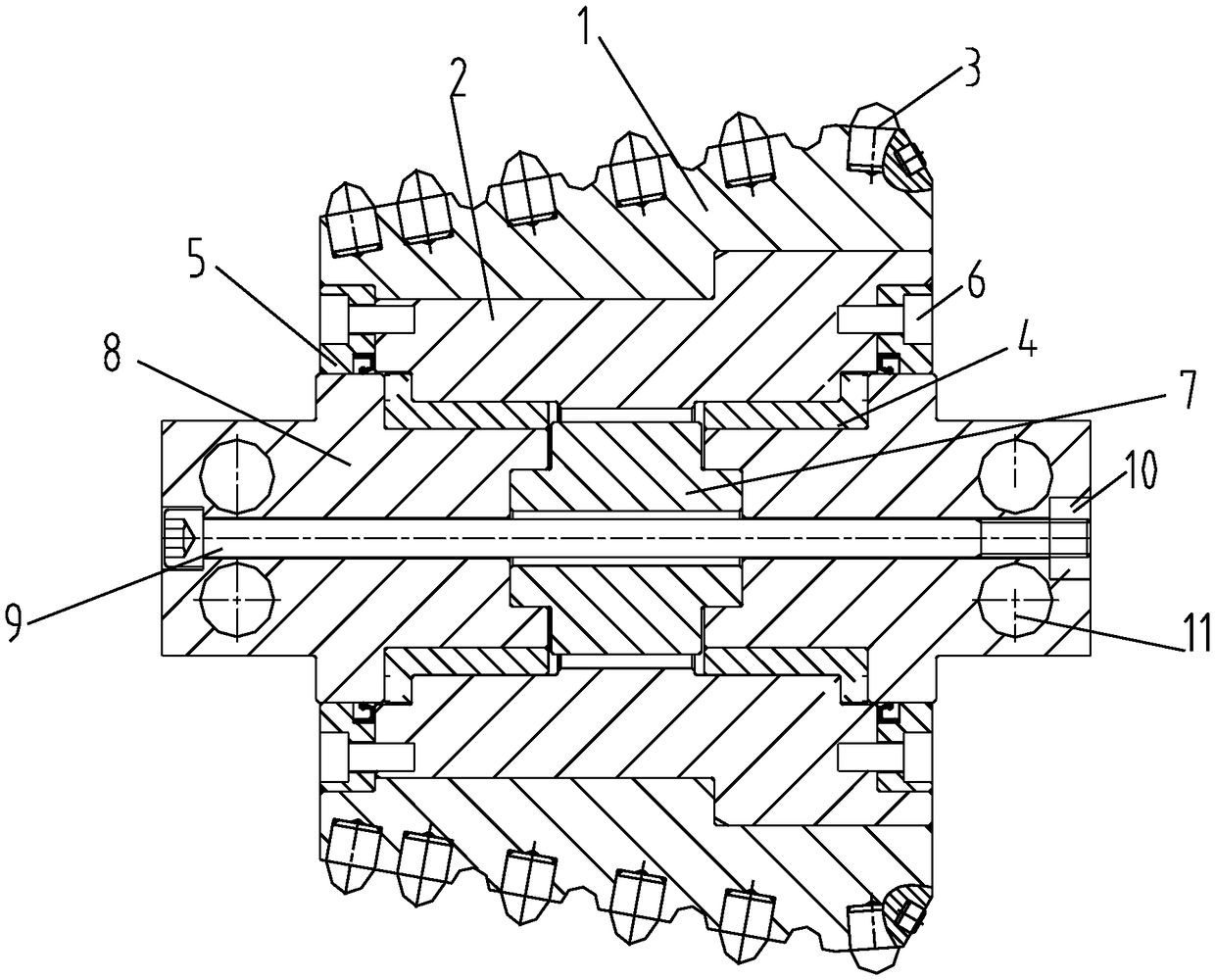

[0022] Such as figure 1 The insertable hob for the sliding bearing raise drilling machine shown can be quickly disassembled, including a cutter housing, an assembled cutter shaft and a rock-breaking insert 3; the cutter housing and the assembled cutter shaft are connected through a sliding bearing 4; the The rock-breaking insert 3 is installed on the outer wall of the cutter housing.

[0023] The knife case includes an outer knife case 1, a knife case core 2 and a gland 5 positioned at both ends of the knife case core 2, and the outer knife case 1 and the knife case core 2 are assembled and fixedly connected by a shrink-fit method; the gland 5 It is fixedly connected with the cutter shell core 2 through gland bolts 6 .

[0024] The knife case adopts a split design, and the knife shell core 2 is forged with bearing steel, which has high impact resistance. The knife shell core 2 is chrome-plated at the contact part with the sliding bearing 4 to improve the wear resistance of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com