Modular multifunctional chain wheel

A multi-functional and modular technology, applied in belts/chains/gears, portable lifting devices, components with teeth, etc., can solve the problems of inconvenient replacement of sprockets, poor self-cleaning effect, etc., to save resources, reduce The effect of waste of resources and reduction of operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings. The embodiments are exemplary and are only used to disclose and explain the present invention so as to fully understand the present invention, but the present invention is not therefore limited within the scope of the described embodiments. .

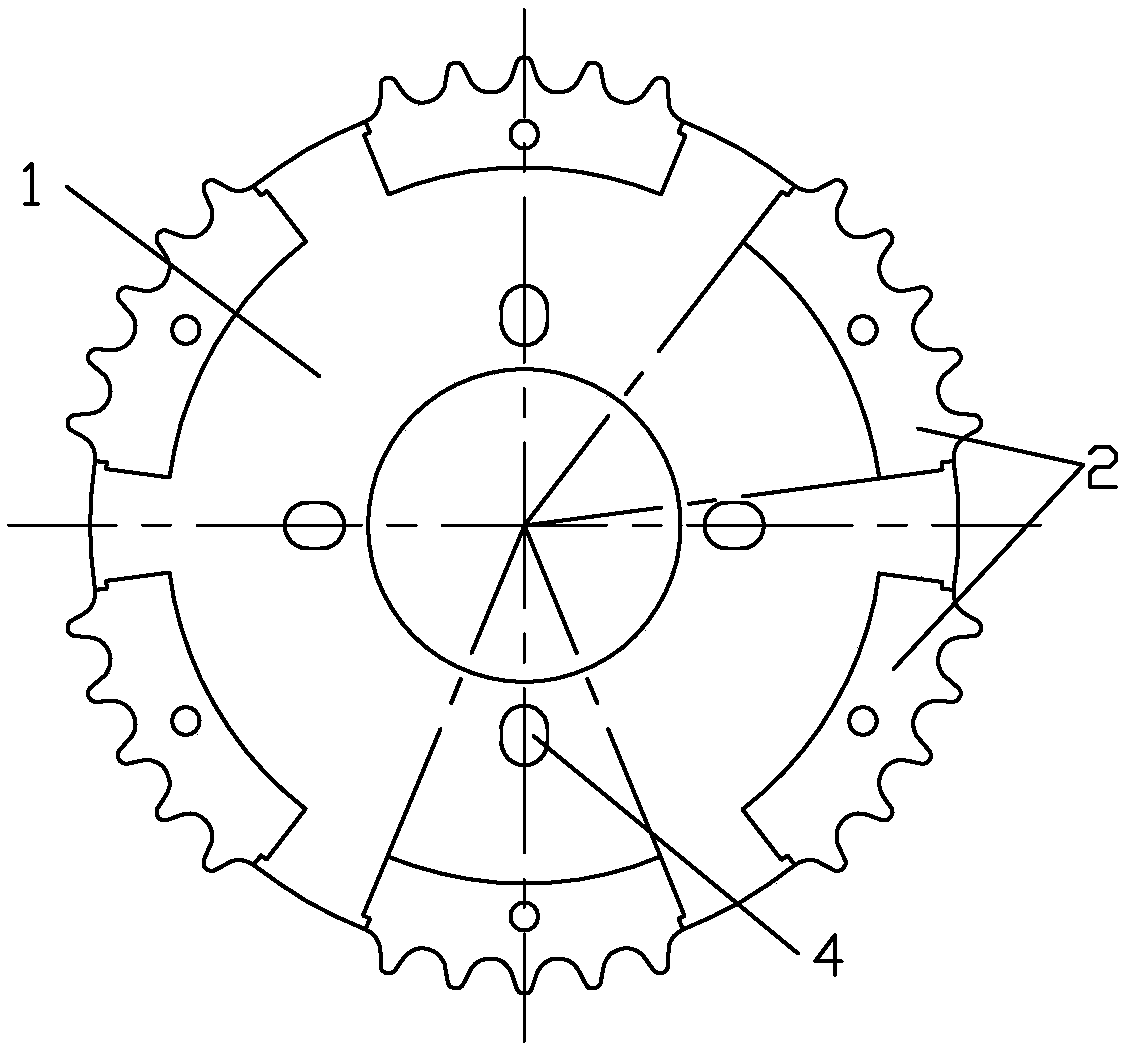

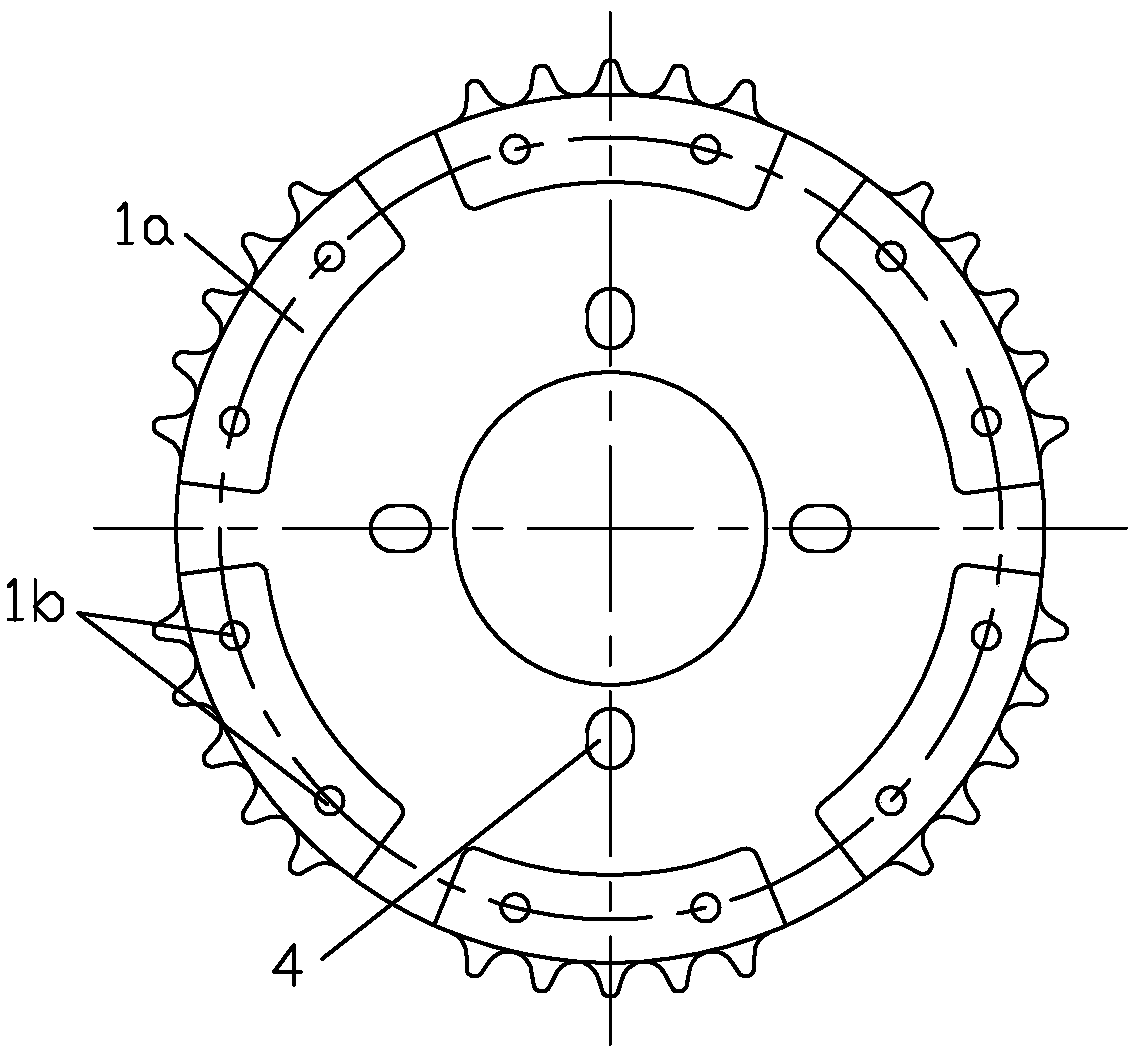

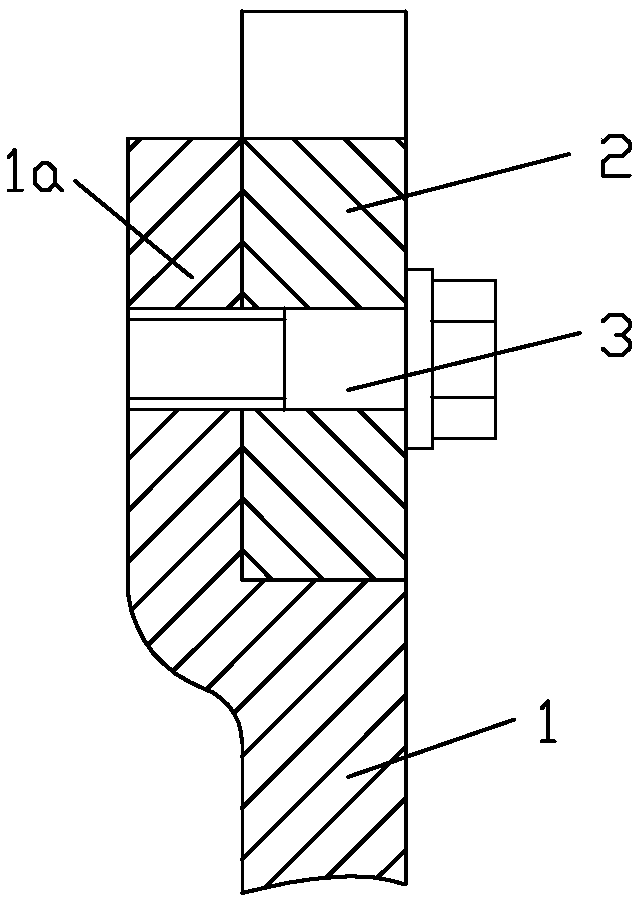

[0020] see figure 1 , figure 2 , image 3 , a modular multi-functional sprocket, comprising a sprocket body 1, sprockets are distributed on the sprocket body 1; the sprockets are formed on a plurality of sprocket segments in a continuous arrangement, and There is an interval segment without sprockets between the adjacent chain teeth on the opposite side of the segment to form an intermittent sprocket structure; and the outer diameter of the sprocket body 1 located at the interval segment is equal to the root circle diameter of the sprocket; the The sprocket segments are formed on an alloy insert 2 , which is embedded on the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com