Industrial high-definition and low-distortion lens with F1.4 large aperture and 12 mm focal length

An industrial lens technology, applied in optics, optical components, installation, etc., can solve the problems of decreased comprehensive imaging power of the lens, high optical sensitivity, and unsatisfactory imaging, so as to enhance the imaging effect, optimize the focusing space, and ensure Effect of Optical Design Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

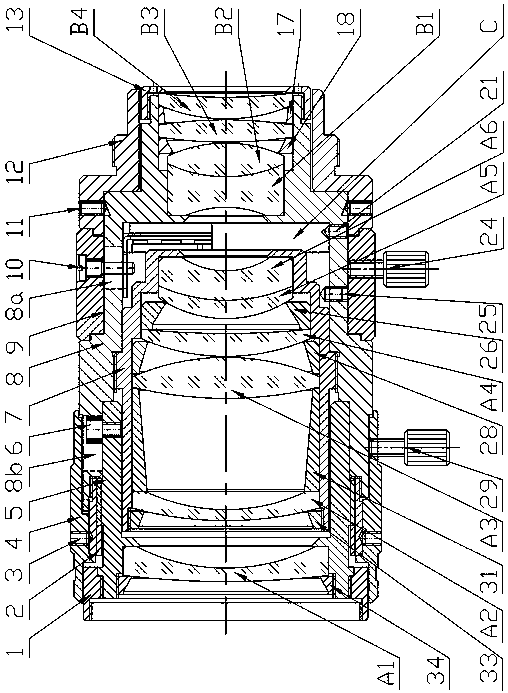

[0024] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

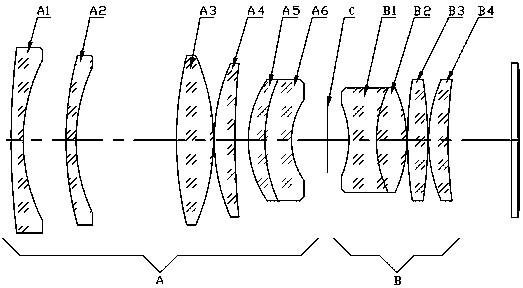

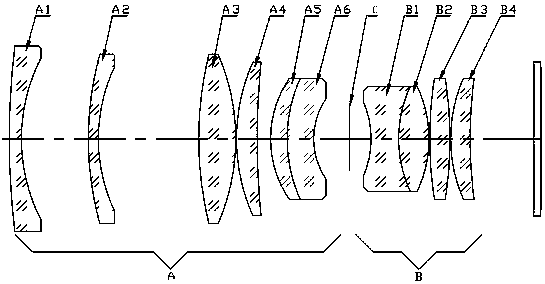

[0025] refer to Figure 1 to Figure 5

[0026] A F1.4 large aperture 12mm focal length high-definition low-distortion industrial lens, including an optical system arranged in the lens structure, the optical system includes front lens groups with negative refractive powers arranged sequentially from front to back along the incident direction of light A, the diaphragm C and the rear lens group B with positive refractive power; the front lens group consists of negative crescent lens A1, negative crescent lens A2, biconvex lens A3, positive crescent lens A4, positive crescent lens A5 and The positive crescent lens A6 is composed of a cemented group closely connected; the rear lens group is composed of a double conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com