Metal core wire integrated connection method of flat cable and flat cable

A connection method and metal core technology, which is applied to the integrated connection of metal core wires of flat cables and the field of flat cables, and can solve problems such as metal wire breakage and heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Hereinafter, the technical contents and effects of the present invention will be better understood by describing specific embodiments of the present invention with reference to the accompanying drawings.

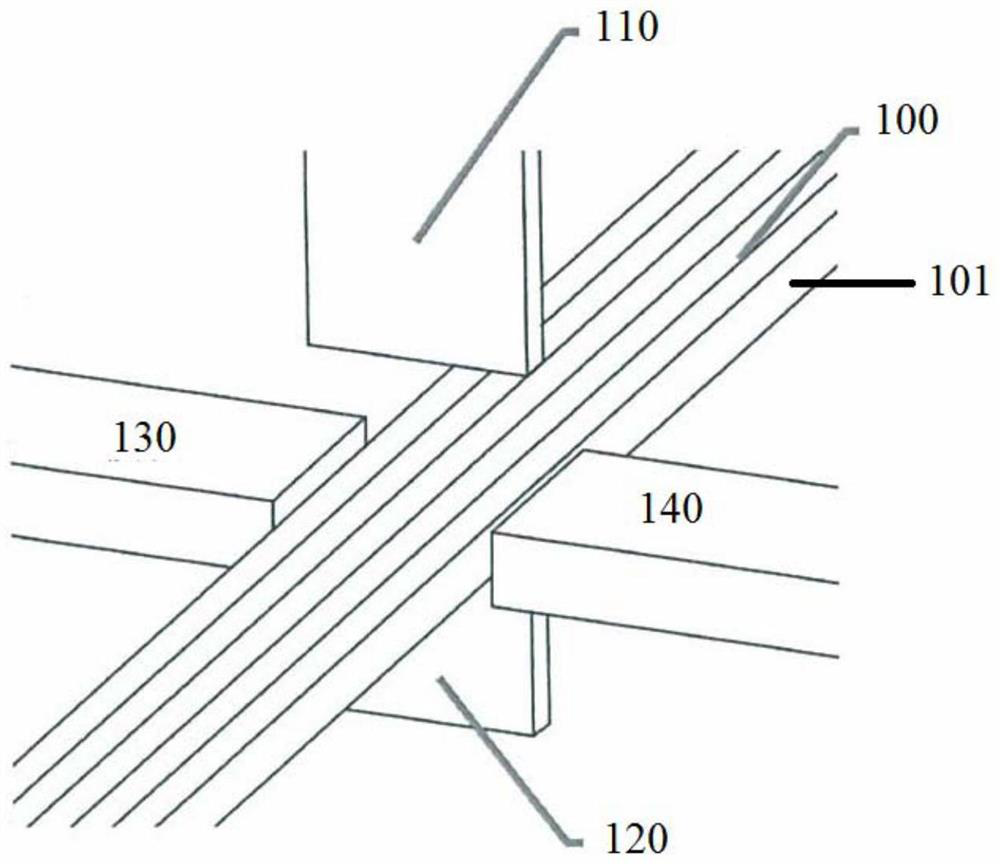

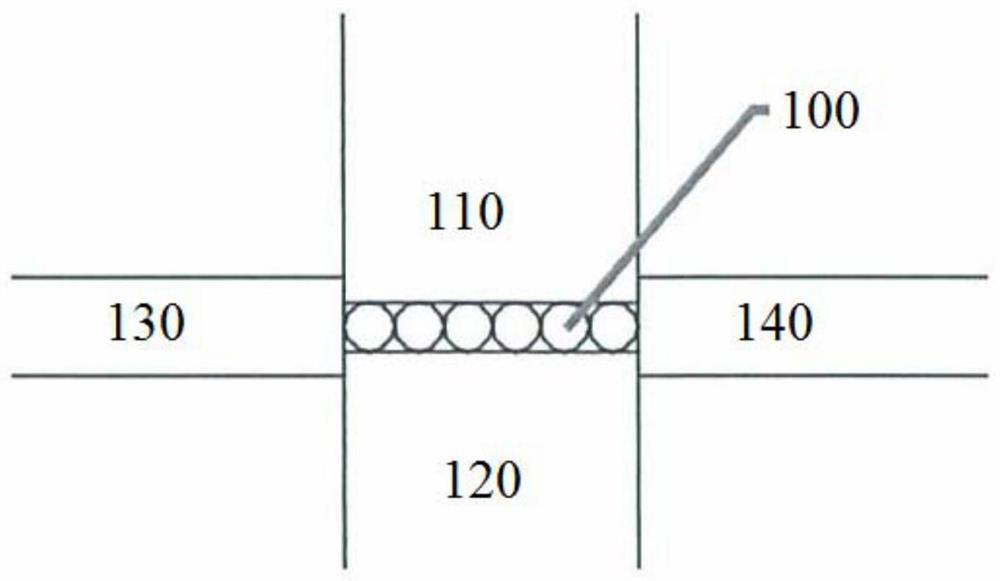

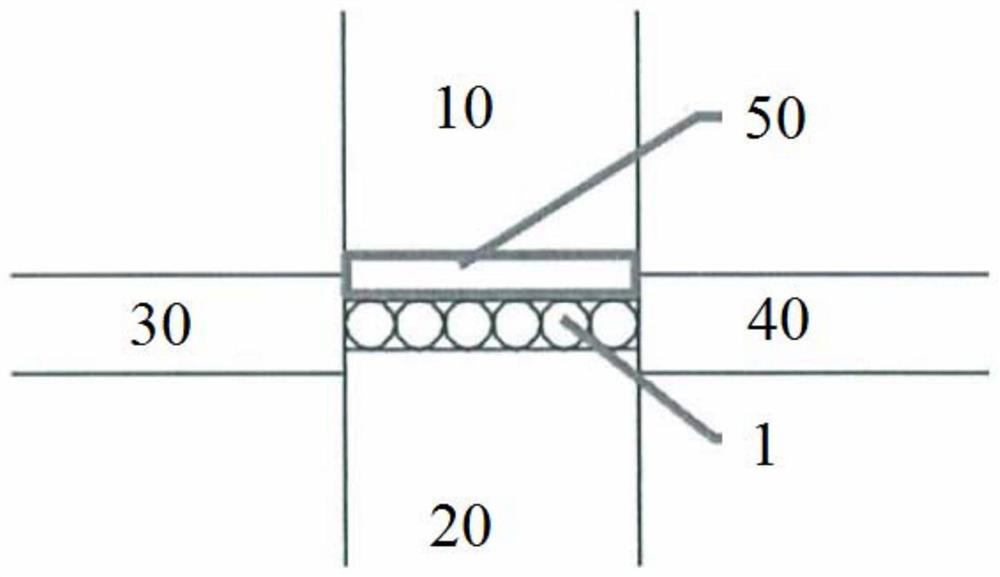

[0037] image 3 The flat cable integrated connection method according to the present invention is shown. The flat cable is the same as the traditional flat cable, which includes a plurality of metal core wires arranged side by side, and each metal core wire has no insulation. In this embodiment, each metal core wire may be a metal core wire formed by twisting or intertwining a plurality of metal wires or a metal core wire formed by a plurality of metal wires closely arranged in parallel, or may be formed by a A metal core wire formed by a metal wire, and each wire has no insulation. The metal core wires or metal wires can be directly purchased commercially available products, or can be obtained by stripping the insulation of the covered electric wires at predetermine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com