Multifunctional combined type woodworking inclined hole drilling jig and clamping device

A multi-functional combination, inclined hole drilling mold technology, applied in wood processing equipment, drilling machines, manufacturing tools, etc., can solve the problems that affect the quality of product splicing and assembly, cannot guarantee the accuracy of two holes, and the inclined hole is easy to skew, etc., to achieve improvement Drilling efficiency, improved drilling accuracy, and easy clamping effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

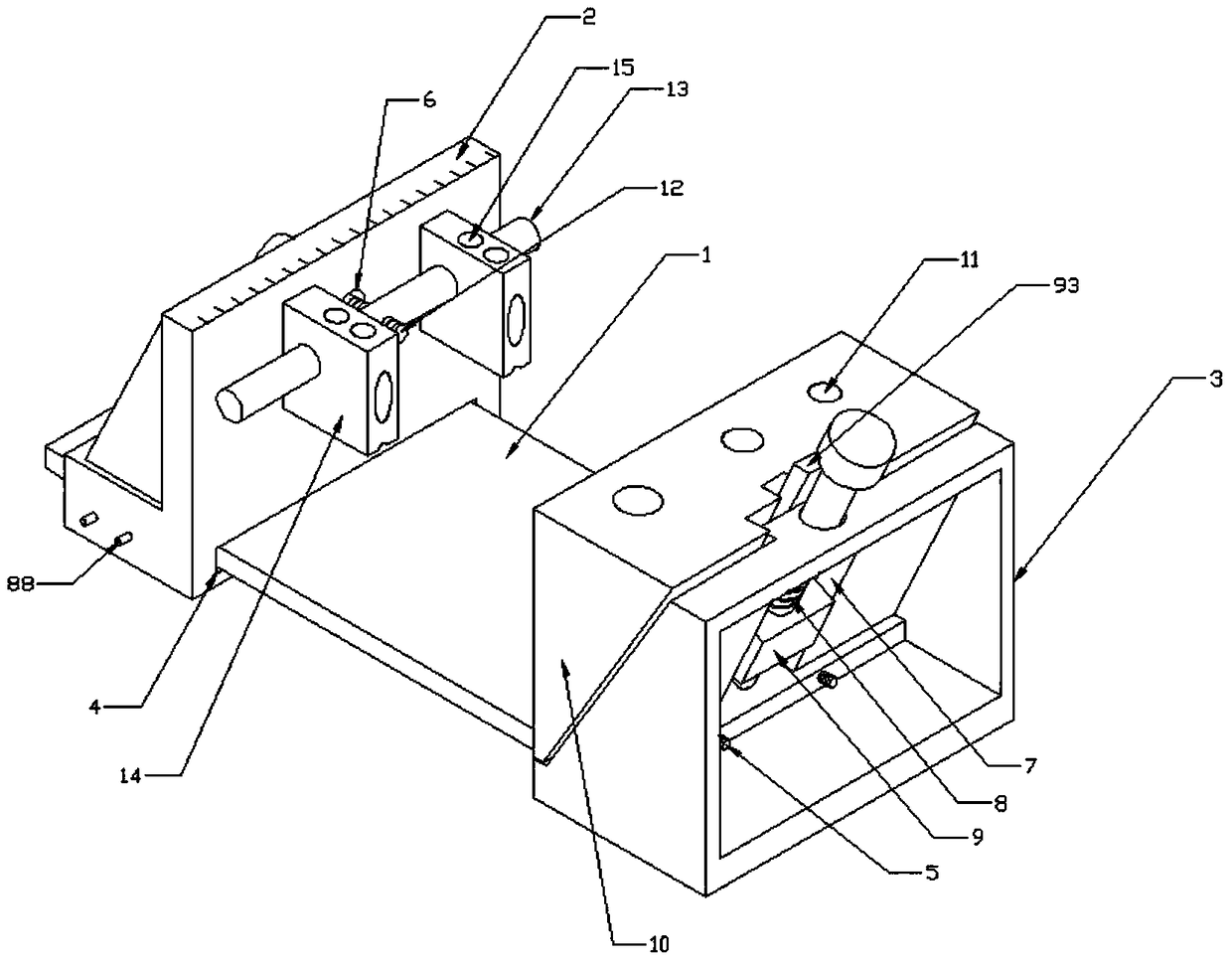

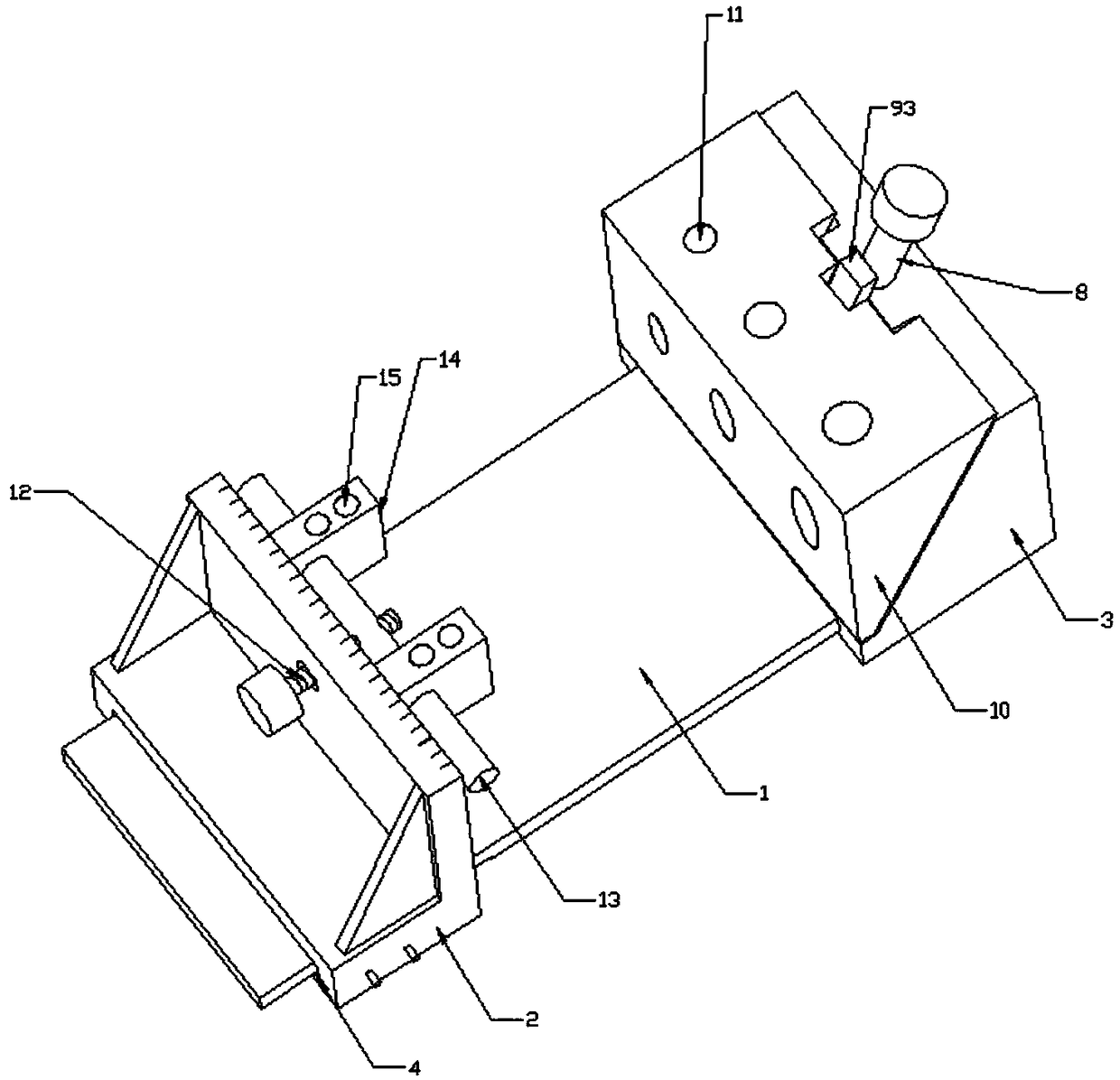

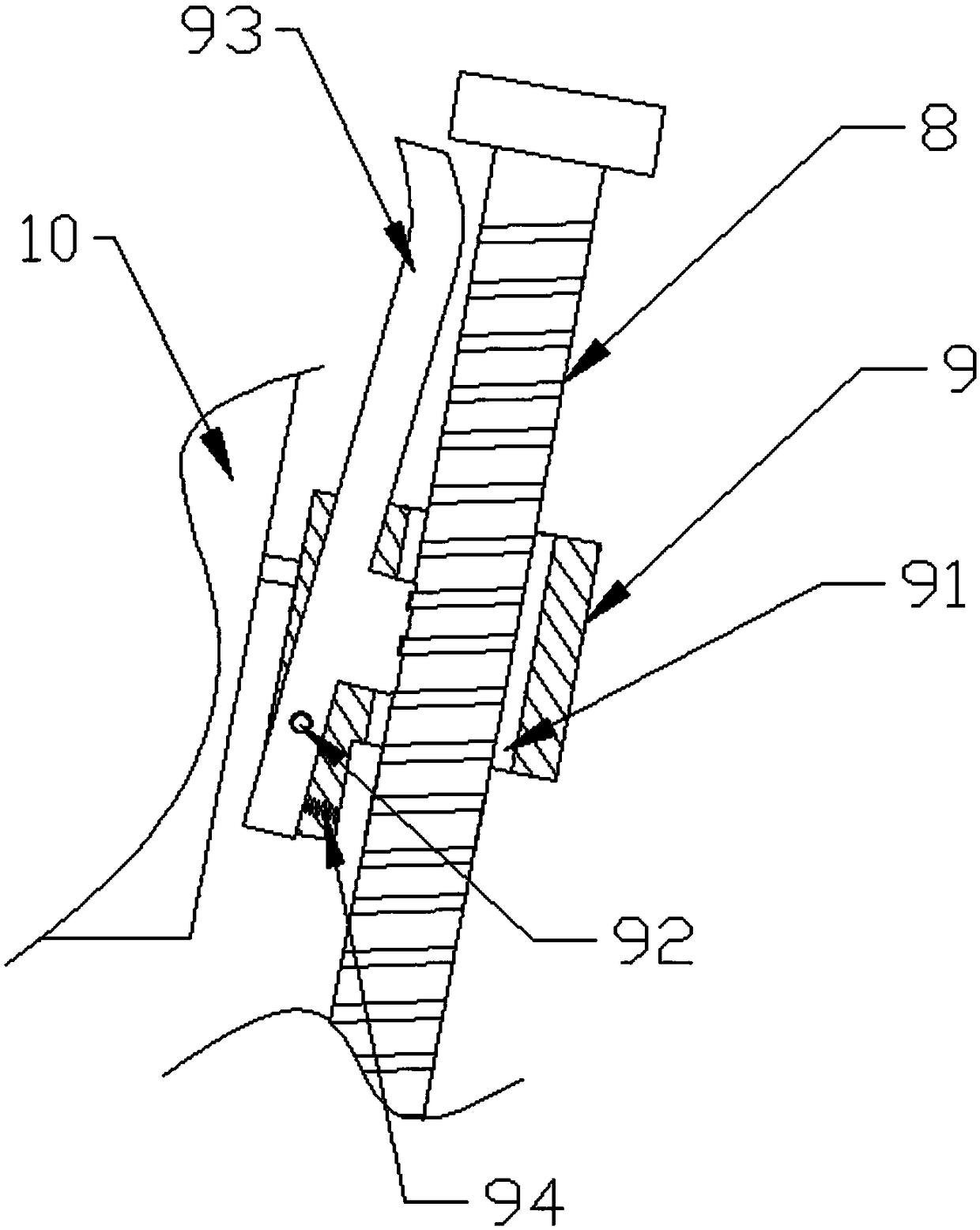

Embodiment 1

[0027] see Figure 1~2 As shown, this embodiment is a multifunctional combined woodworking inclined hole drilling mold and clamping device, including a bottom plate 1, a left bracket 2 and a right bracket 3, the lower part of the left bracket 2 is provided with a socket 4, and the left end of the bottom plate 1 runs through Socket 4, the bottom of right bracket 3 is screwed with locking thick nail 5, and the left end of locking thick nail 5 stretches into the right side wall of base plate 1, and the upper part of left bracket 2 is provided with through hole 6, and the left side of right bracket 2 The wall is provided with a chute 7, the inner chamber of the chute 7 is provided with a screw mandrel 8, the screw mandrel 8 is threadedly connected with a nut seat 9, the left side of the nut seat 9 is connected with a drilling mold wedge 10, and the drilling mold wedge 10 The upper part is provided with three groups of drilling mold holes 11 of different diameters; the right part o...

Embodiment 2

[0033] see Figure 1~2 As shown, this embodiment is a multifunctional combined woodworking inclined hole drilling mold and clamping device, including a bottom plate 1, a left bracket 2 and a right bracket 3, the lower part of the left bracket 2 is provided with a socket 4, and the left end of the bottom plate 1 runs through Socket 4, the bottom of right bracket 3 is screwed with locking thick nail 5, and the left end of locking thick nail 5 stretches into the right side wall of base plate 1, and the upper part of left bracket 2 is provided with through hole 6, and the left side of right bracket 2 The wall is provided with a chute 7, the inner chamber of the chute 7 is provided with a screw mandrel 8, the screw mandrel 8 is threadedly connected with a nut seat 9, the left side of the nut seat 9 is connected with a drilling mold wedge 10, and the drilling mold wedge 10 The upper part is provided with three groups of drilling mold holes 11 of different diameters; the right part o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap