Waste rubber sorting device

A sorting device and waste rubber technology, applied in recycling technology, plastic recycling, etc., can solve problems such as high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through specific implementations:

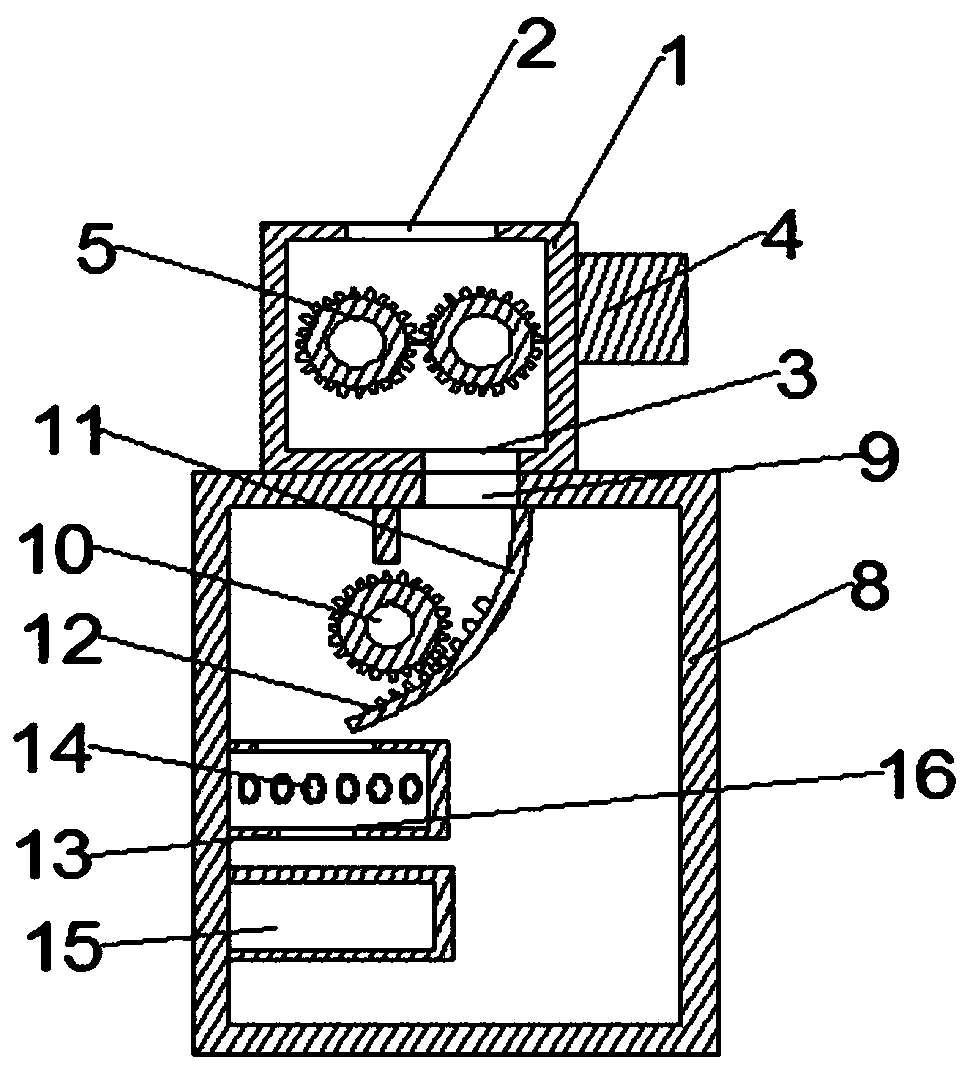

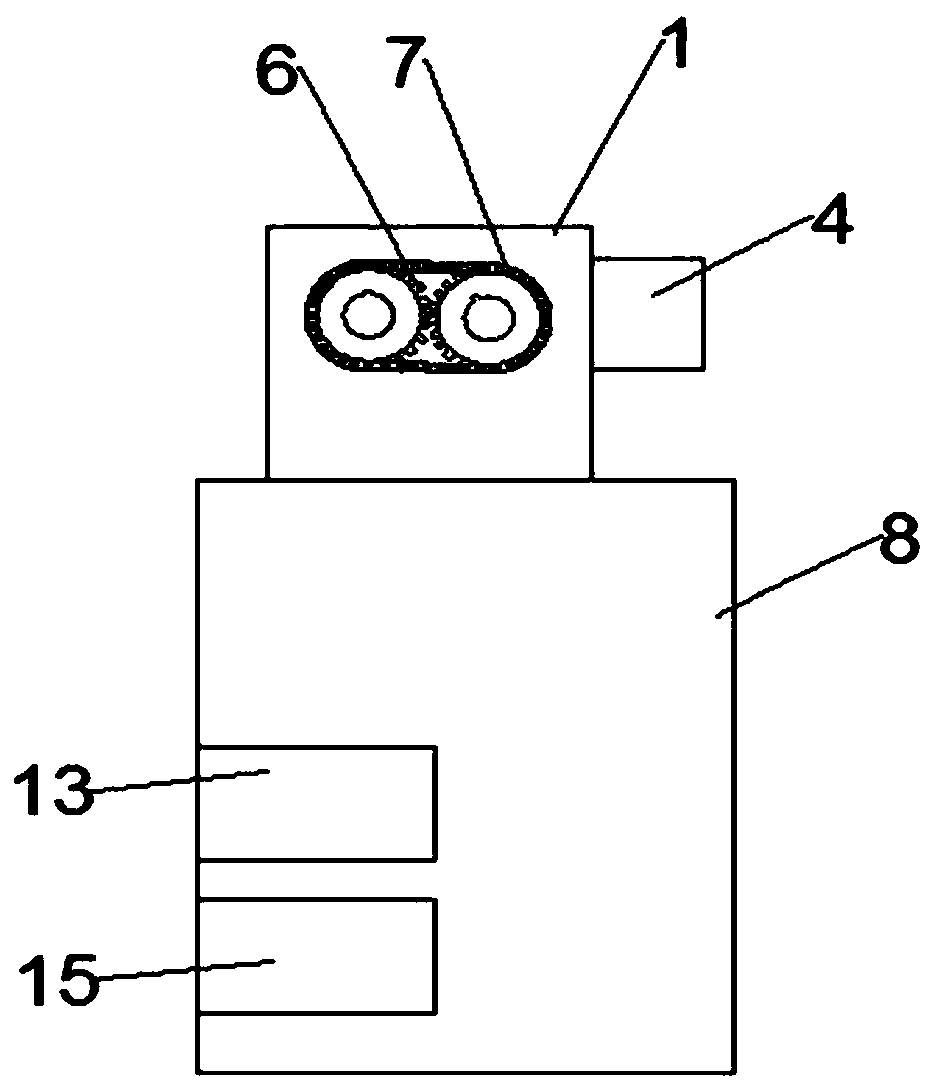

[0017] The reference signs in the drawings of the specification include: separation cabinet 1, first feed port 2, first discharge port 3, first motor 4, counter roller 5, gear 6, chain 7, sorting cabinet 8, second The feed port 9, the drum 10, the arc-shaped plate 11, the saw teeth 12, the first discharging trough 13, the sorting tube 14, the second discharging trough 15, and the opening 16.

[0018] As attached figure 1 And figure 2 Shown: a sorting device for waste rubber, a separation mechanism and a sorting mechanism, the separation mechanism is located above the separation mechanism, the separation mechanism includes a separation cabinet 1, the top of the separation cabinet 1 is provided with a first inlet Material port 2, the bottom of the separation cabinet 1 is provided with a first discharge port 3, one side of the separation cabinet 1 is provided with a first motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com