A bathtub production process

A production process and bathtub technology, which is applied in the field of sanitary ware, can solve the problems of cumbersome production process of acrylic plastic bathtubs, the inability to prepare bathtubs with concave-convex patterns, and the inability to inspect the quality of bathtubs, etc., so as to achieve convenient operation for workers, save materials, and ingenious structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

[0036] Among them, the main component of the drier mentioned in this application is methyl ethyl ketone peroxide, which was purchased from Futian Chemical Industry Co., Ltd., Zhaoqing City, Guangdong Province.

[0037] A bathtub production process mainly comprises the following steps:

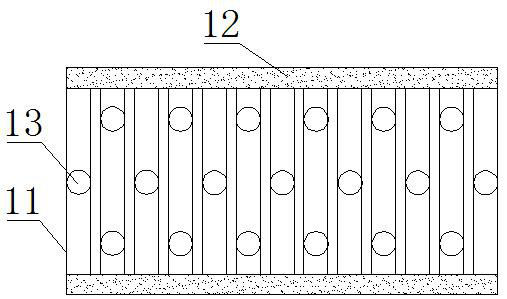

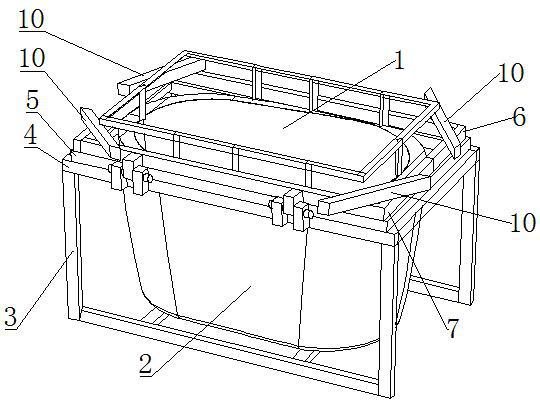

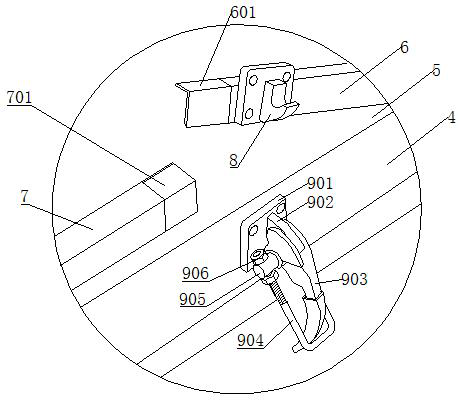

[0038] Prefabrication: heating and softening the acrylic sheet, placing it on the cavity mouth of the bathtub mold with a clip structure, fixing it and performing plastic molding, and using molds with different cavity shapes to obtain the inner cylinder and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com