Push-pull tire energy recovery device

An energy recovery device, push-pull technology, applied in the direction of wheels, vehicle parts, transportation and packaging, etc., can solve the problem that the energy of automobile tires cannot be recovered, and achieve the effect of stable recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

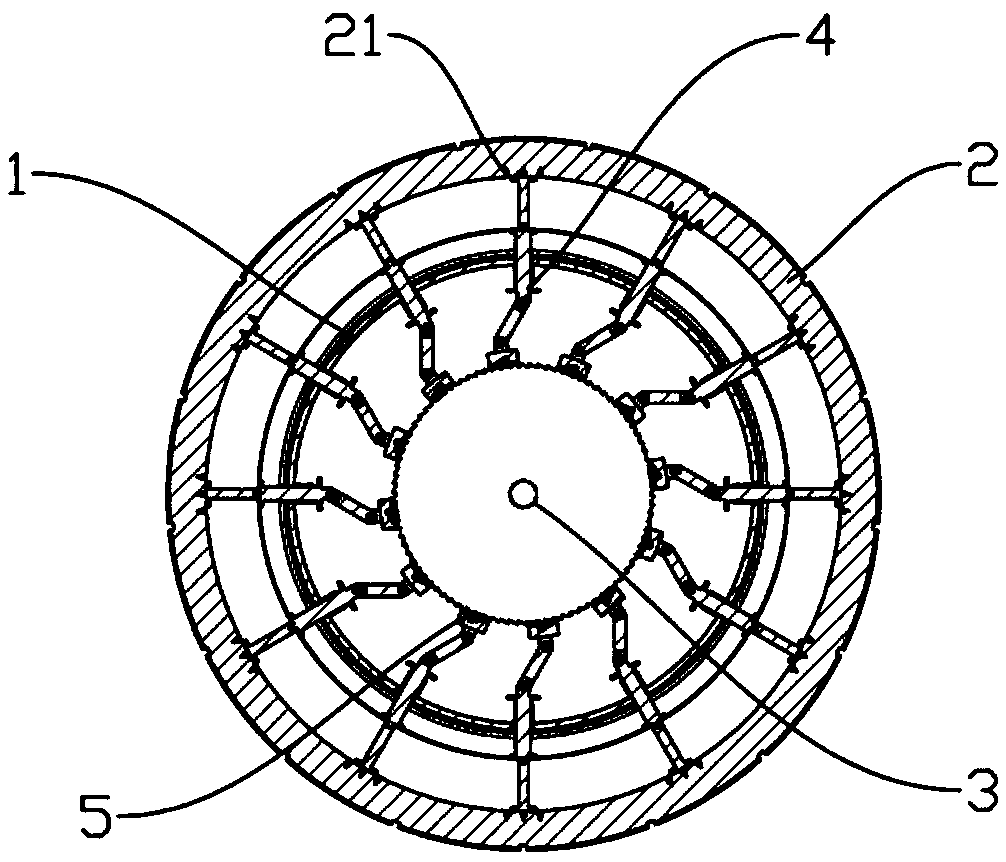

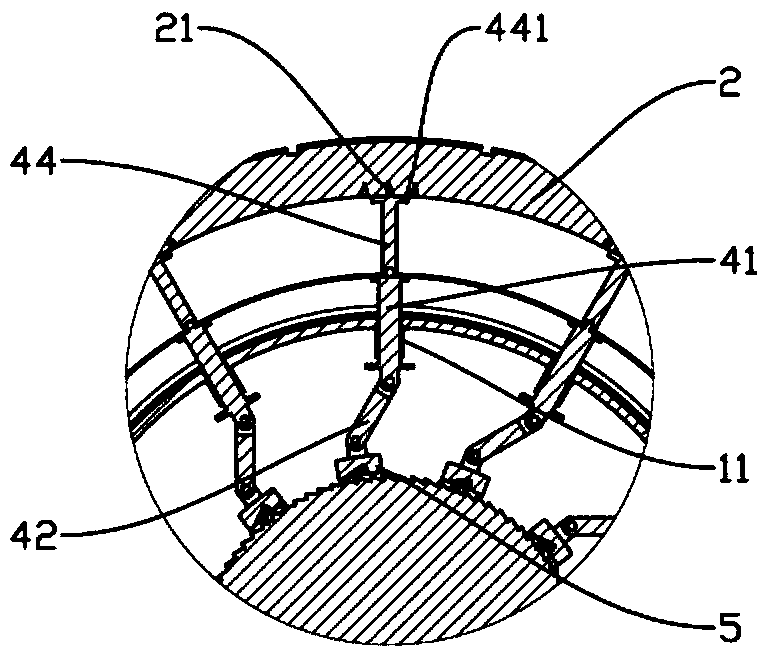

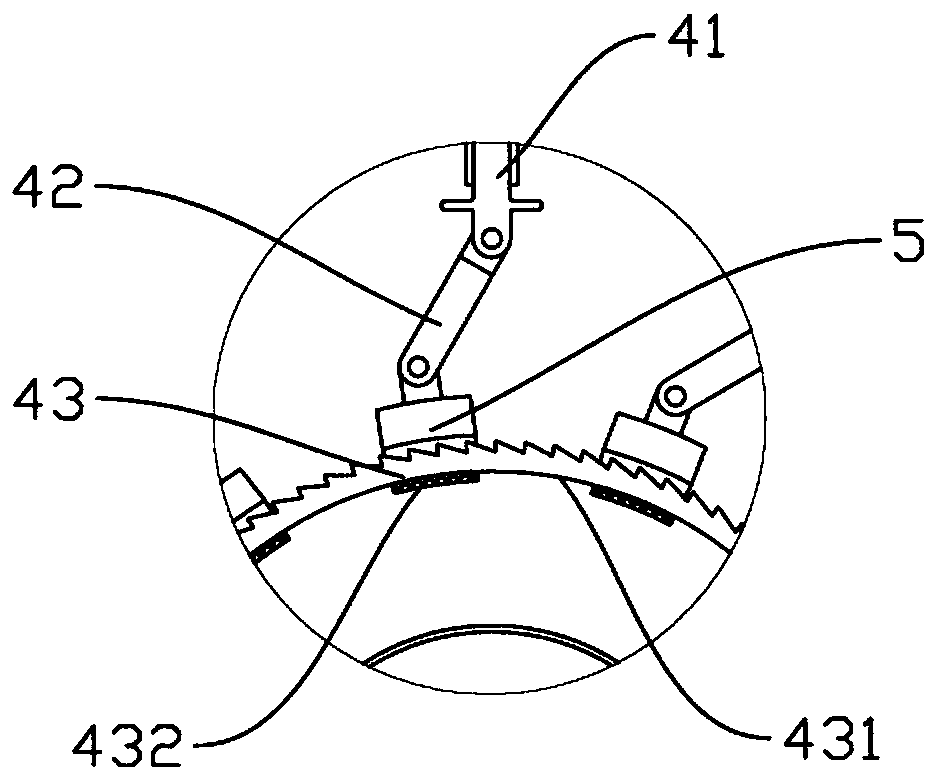

[0025] combine Figure 1 to Figure 6 As shown, the push-pull tire energy recovery device of the present invention is schematically shown, including a hub 1 , a tire 2 installed on the outer circumference of the hub 1 , an output shaft 3 and a plurality of energy-taking devices 4 . Such as figure 2 The energy harvesting device 4 includes a transmission rod 44, a first part 41 and a second part 42. The first part 41 is movably installed on the hub 1 and can slide radially along the hub 1. There are a plurality of guide cylinders 11, the center line of the guide cylinder 11 coincides with the radius line of the hub 1, and the first part 41 is movably installed in the guide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap