Conveying device for solar cell panel chip

A technology of solar panels and conveying devices, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low chip conveying efficiency, achieve the effects of reducing human adjustments, improving efficiency, and improving assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

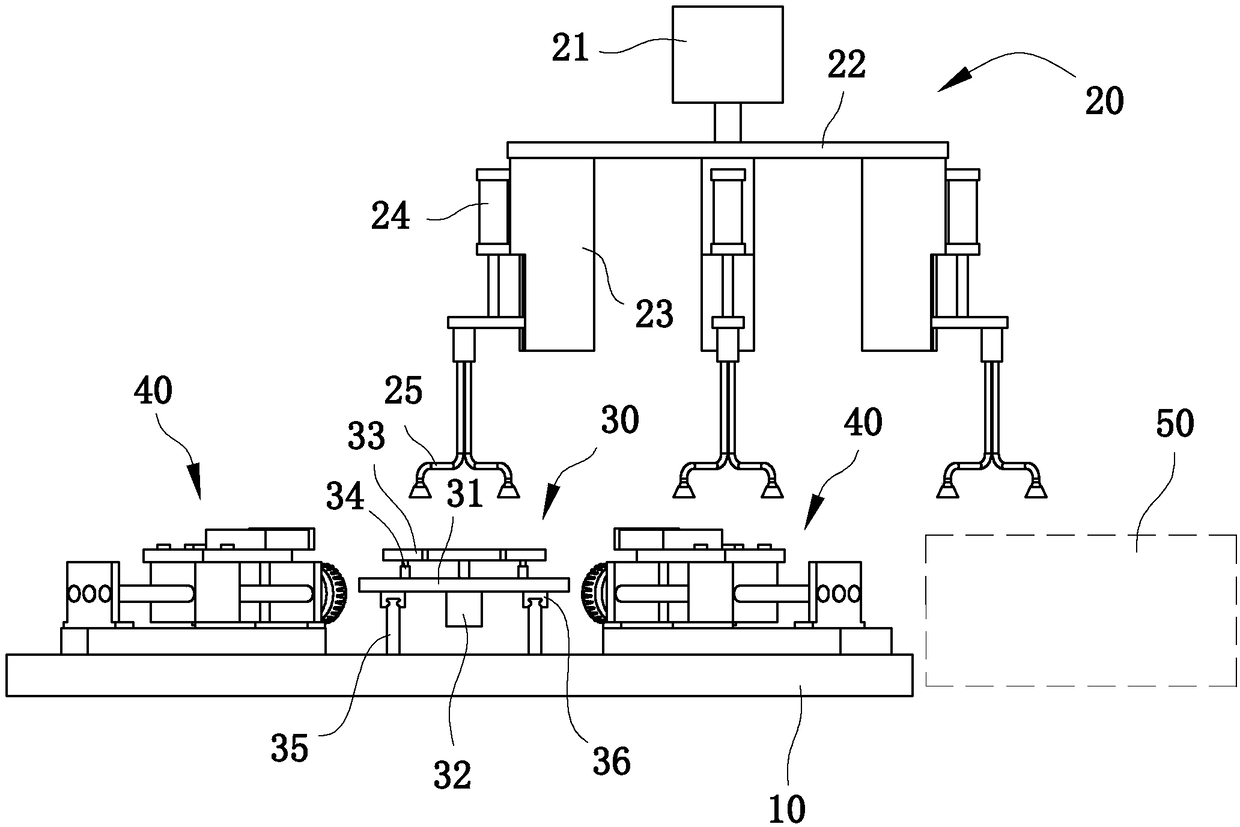

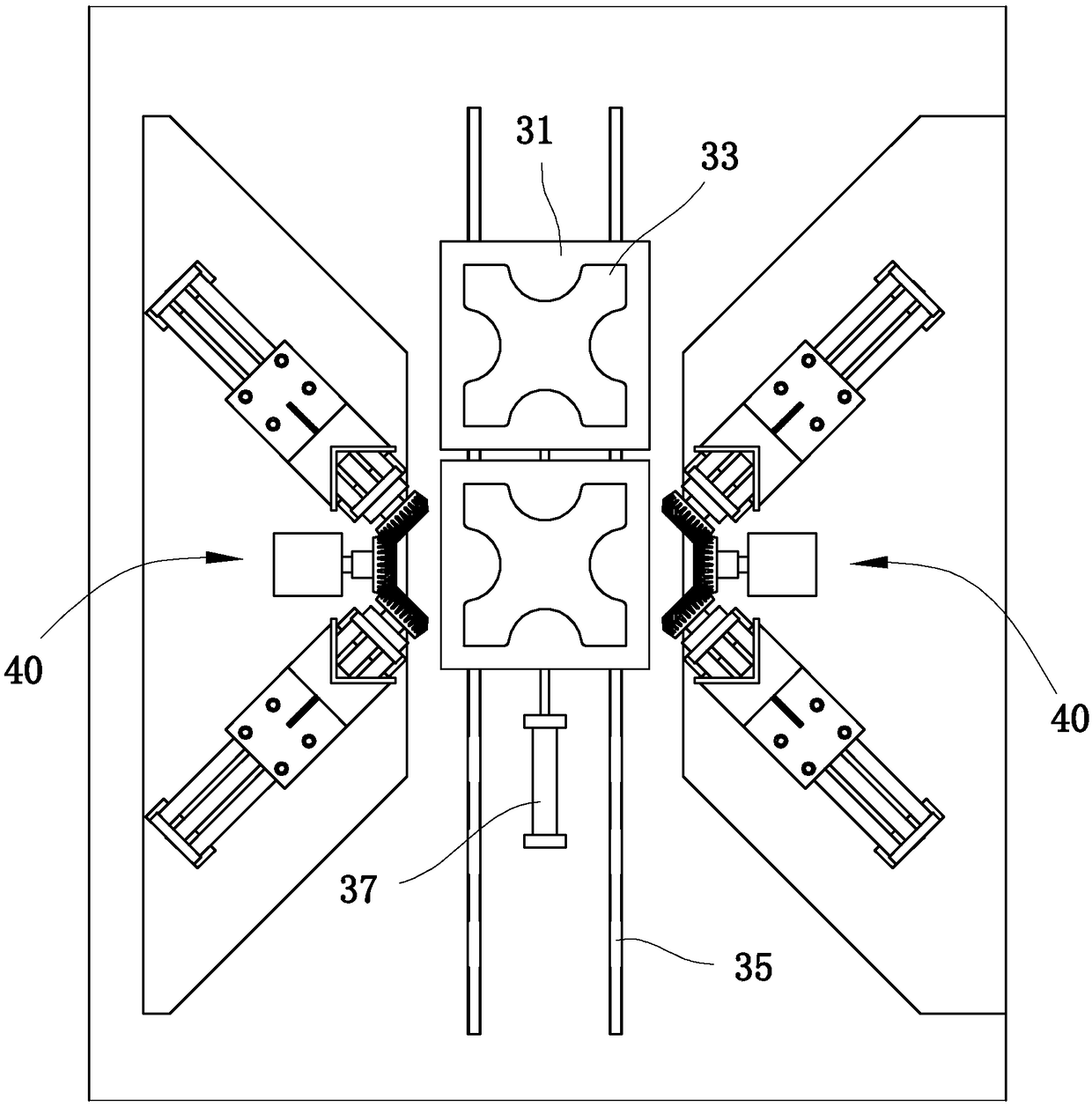

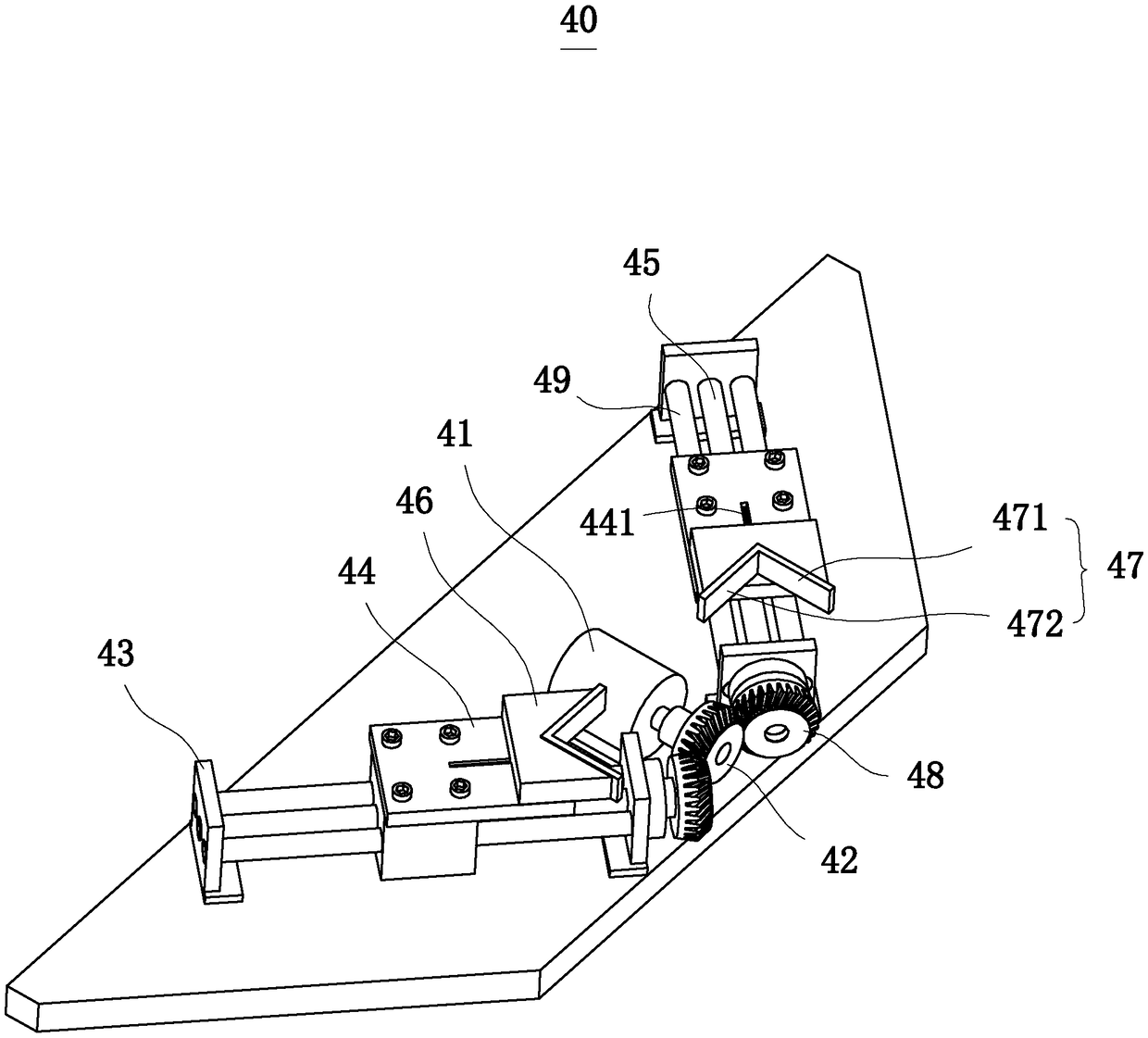

[0045] refer to figure 1 , a delivery device for solar panel chips, including a workbench 10, a storage mechanism 30 located on the workbench 10, a leveling mechanism 40 located on the left and right sides of the storage mechanism 30, and a drive mechanism 20 located above the workbench 10. The drive mechanism 20 is installed and fixed on the frame as a whole (not shown in the figure), and includes a rotating cylinder 21, a turntable 22 connected to the turntable 21, and several sucker grabbing components arranged on the turntable 22. In this embodiment, the sucker catches There are also four groups of components, which are evenly distributed on the outer peripheral surface of the rotating disk 22 in the circumferential direction.

[0046] The suction cup grabbing assembly specifically includes a connecting frame 23 installed and fixed on the turntable 22 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com