Raw material rewinding mechanism

A raw material and feeding technology, applied in the field of disposable sanitary products, can solve the problems of large rewinding and swinging moving parts, high cost, and high energy consumption, and achieve the effects of convenient transportation, installation and debugging, uniform density, and low motion inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

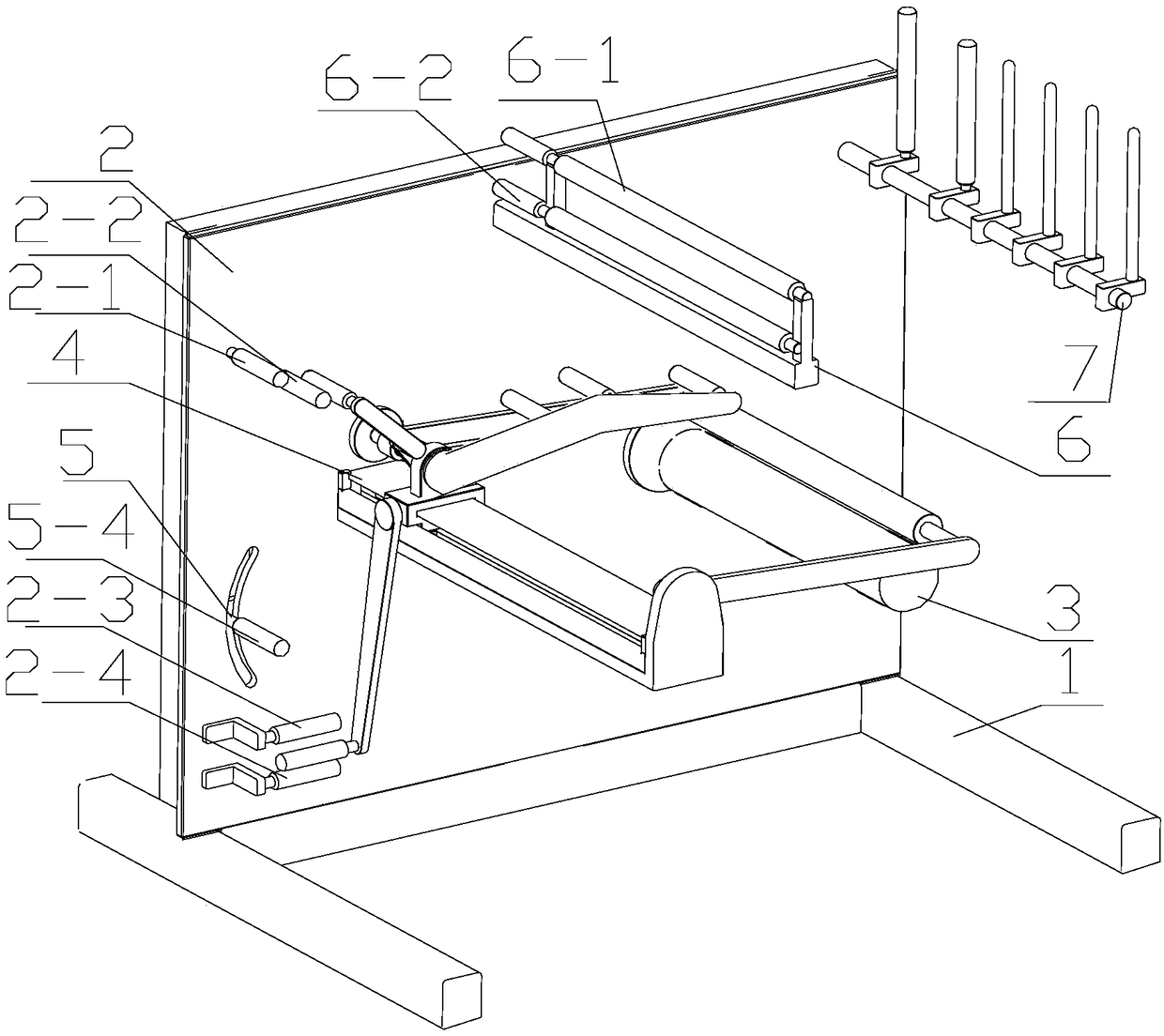

[0030] Such as Figure 1~3 . A rewinding mechanism for raw materials, including a main frame 1, a mounting panel 2 is fixed on the main frame 1, a rewinding device 3 is rotatably connected to the mounting panel 2, and a reciprocating The moving reciprocating swing rod assembly 4 includes a swing arm and a material wheel assembly mounted on the swing arm for guiding the material to the winding device 3, and the reciprocating swing rod assembly 4 is mounted on the installation panel. There is also a guide wheel assembly upstream.

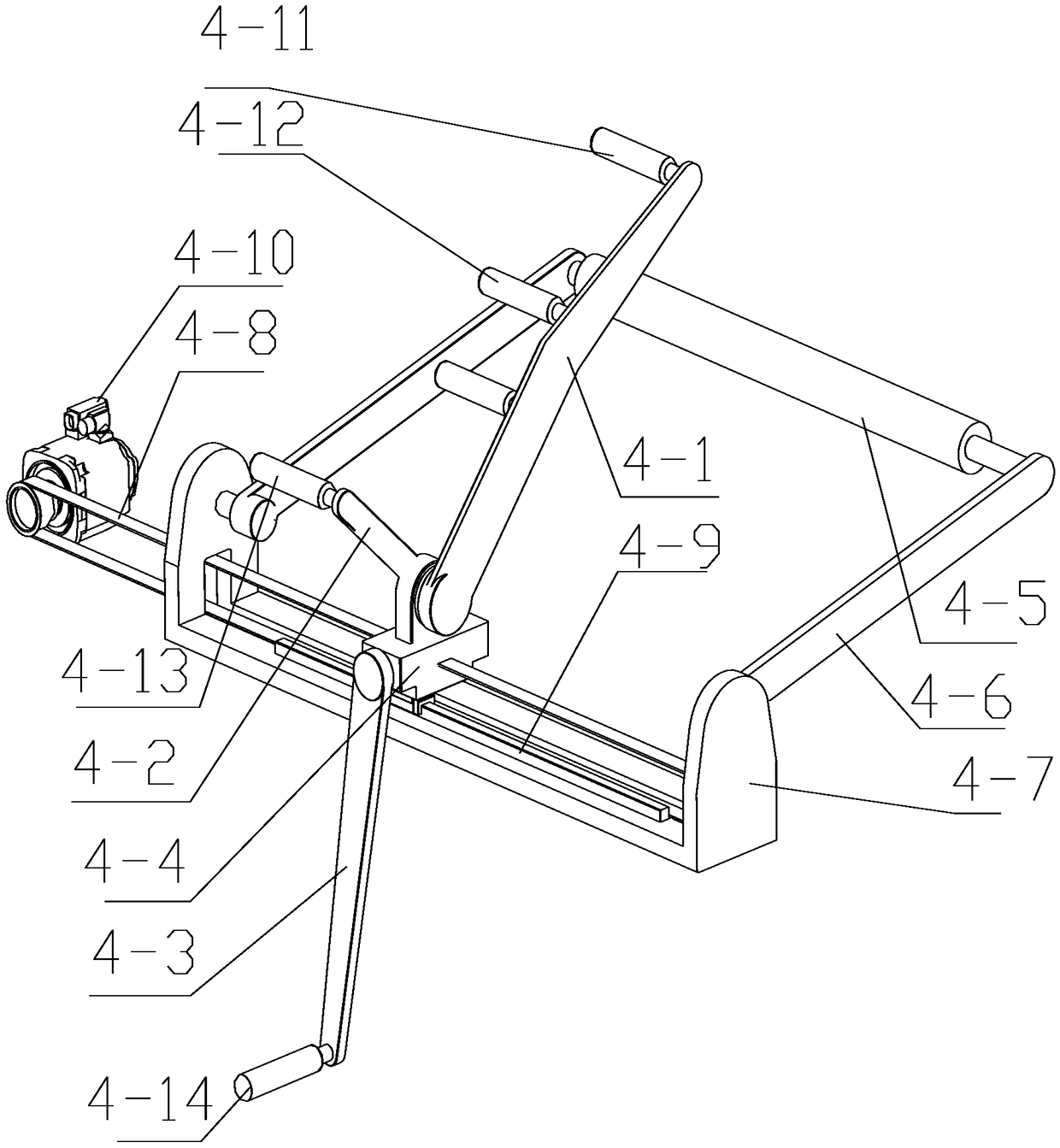

[0031] The mounting panel 2 is fixed with a swing arm fixed base 4-7, and the swing arm fixed base 4-7 is rotated to be provided with a winding material pinch wheel swing arm 4-6, and the winding material pinch wheel swing arm 4-6 ends Rolling material pressure wheels 4-5 for guiding the material to the winding device 3 are connected in rotation;

[0032] The swing arm fixed base 4-7 is fixed with a precision guide rail 4-9, and the slide table base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com