Wind power driving type salt field bittern evaporation system and method

An evaporation system and driving technology, applied in the field of wind-driven salt field brine evaporation system, can solve the problems of restricting the increase of production capacity of salt-making enterprises, large salt field area, slow evaporation rate, etc. The effect of salt efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

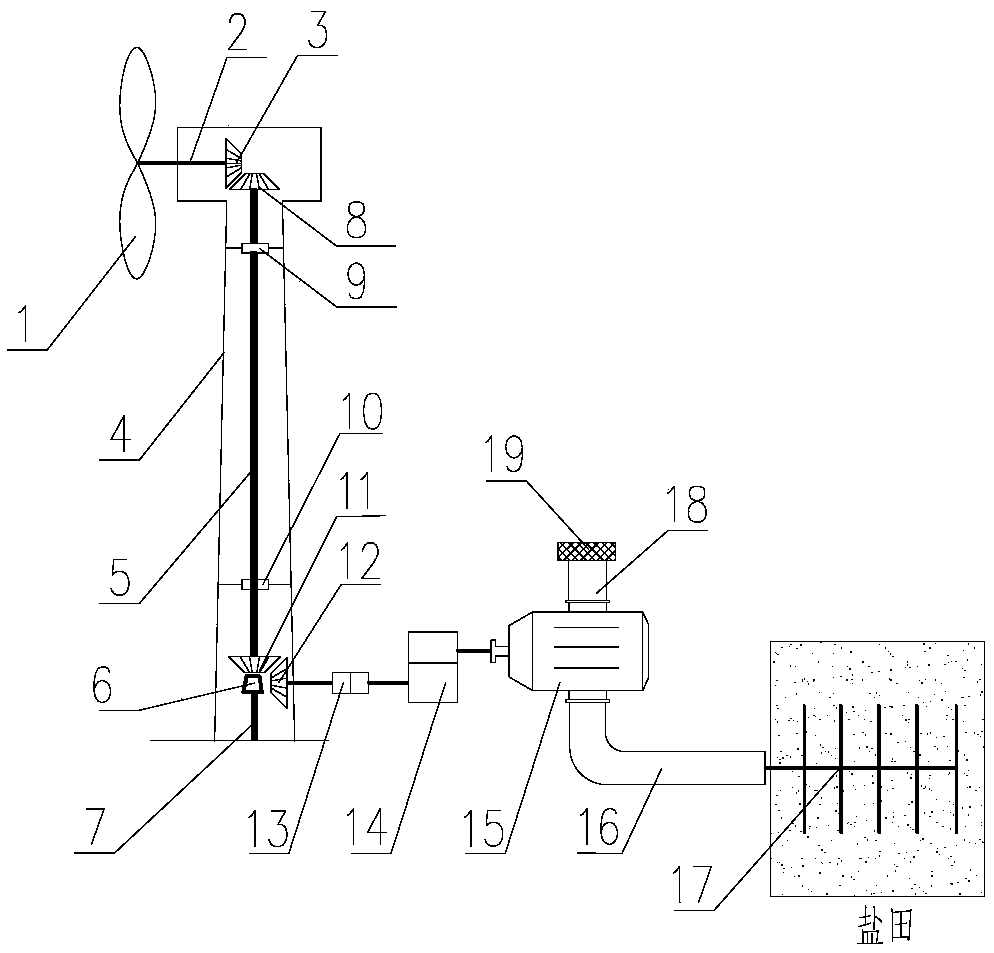

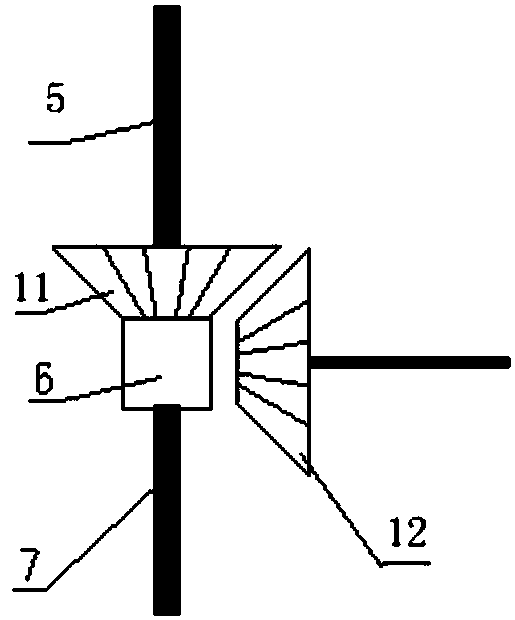

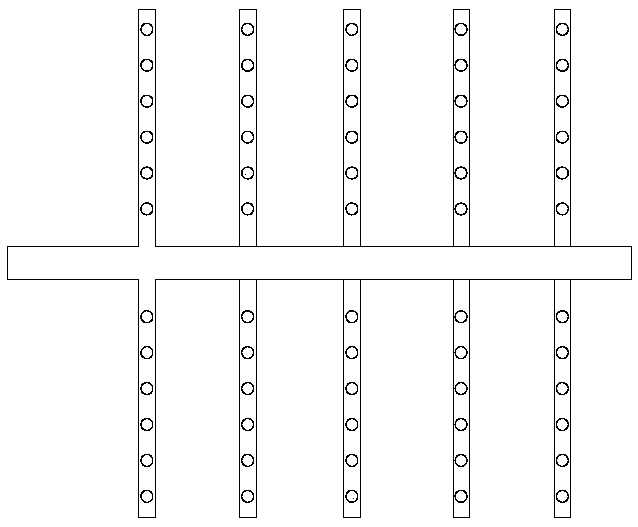

[0023] Such as figure 1 As shown, a wind-driven salt field brine evaporation system and method include a fan blade 1, a fan shaft 2, a first bevel gear 3, a tower 4, a transmission shaft 5, a thrust bearing 6, a support rod 7, a second Bevel gear 8, upper bearing 9, lower bearing 10, third bevel gear 11, fourth bevel gear 12, clutch 13, transmission gearbox 14, compressor 15, exhaust pipe 16, aeration pipe 17, inlet Air pipe 18, intake pipe filter 19. The fan blade 1 adopts a three-leaf blade, and the fan blade is installed on one end of the fan shaft 2, and the other end of the fan shaft is equipped with a first bevel gear 3; the tower 4 is a hollow cone structure, and the fan blade and the fan shaft The drive shaft is mounted on the top of the tower. The transmission shaft 5 is built inside the tower along the direction of the central axis of the tower, and the second bevel gear 8 is installed on the upper end of the transmission shaft, and the first bevel gear and the sec...

Embodiment 2

[0026] Such as Figure 4 As shown, a wind-driven salt field brine evaporation system and method include a fan blade 1, a tower frame 4, a transmission shaft 5, a thrust bearing 6, a support rod 7, an upper bearing 9, a lower bearing 10, and a third bevel gear 11. The fourth bevel gear 12, the clutch 13, the transmission gearbox 14, the compressor 15, the exhaust pipe 16, the aeration pipe 17, the intake pipe 18, and the intake pipe filter 19 are composed. The fan blade 1 adopts a spiral ribbon blade and is installed on the top of the transmission shaft; the tower 4 is a hollow cone structure, and the fan blade and the fan transmission shaft are installed on the top of the tower. The transmission shaft 5 is built inside the tower along the central axis of the tower; the upper bearing 9 is coaxially installed with the transmission shaft and fixed at the upper position of the tower; the lower bearing 10 is coaxially installed with the transmission shaft , and fixed at the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com