Hydration heat suppression type expansion fiber composite anti-cracking agent and preparation method thereof

A heat-of-hydration suppression and fiber-expanding technology, which is applied in the field of building materials, can solve problems such as unfavorable prevention of early cracks in concrete, low early effective compensation of concrete, and reduction of peak hydration heat release rates, so as to increase crack resistance and improve Anti-cracking performance, the effect of reducing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

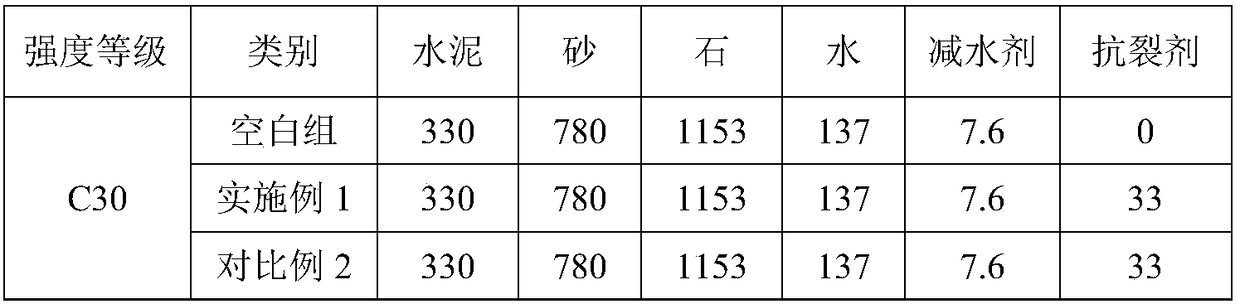

Embodiment 1

[0036] A hydration heat-inhibiting expansion fiber composite anti-cracking agent comprises: 95% of an expansion component; 3.5% of a hydration heat-inhibiting component; and 1.5% of a basalt fiber.

[0037] Among them, the expansion component is composed of a light-burned magnesia expansion agent and a calcium expansion agent at a mass ratio of 10:1. The MgO content in the light-burnt magnesia expansion agent is 82.7wt%, and the hydration activity value t is 60s, which is relatively Surface area is 320m 2 / kg, the 1.18mm sieve residue is 0.3%; the calcium expansion agent is a calcium oxide-calcium sulfoaluminate composite expansion agent, and the content of free calcium oxide (f-CaO) in the calcium expansion agent is 47.72wt%, and the specific surface area is 265m 2 / kg, 1.18mm sieve is 0.6%.

[0038]The heat of hydration inhibitor component is composed of methyl stearate and sodium hexametaphosphate in a mass ratio of 3:1.

[0039] The nominal diameter of monofilament of ba...

Embodiment 2

[0045] This example is basically the same as Example 1, except that the expansion component is composed of a light-burned magnesia expansion agent and a calcium expansion agent at a mass ratio of 3:1, and the MgO content in the light-burned magnesia expansion agent 82.2wt%, the hydration activity value t is 100s, and the specific surface area is 340m 2 / kg, 1.18mm sieve is 0.2%.

Embodiment 3

[0047] This example is basically the same as Example 1, except that the expansion component is composed of a light-burned magnesia expansion agent and a calcium expansion agent at a mass ratio of 1:3, and the MgO content in the light-burned magnesia expansion agent 80.2wt%, the hydration activity value t is 160s, and the specific surface area is 330m 2 / kg, 1.18mm sieve is 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com