Inspection method of streamline of blade of stainless steel die forging and preparation method of corrosive solution

A stainless steel mold and inspection method technology, applied in the field of physical and chemical inspection, can solve the problems of streamline corrosion, difficulty in judging product quality, and inability to determine the streamline, and achieve the effect of determining the service life of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

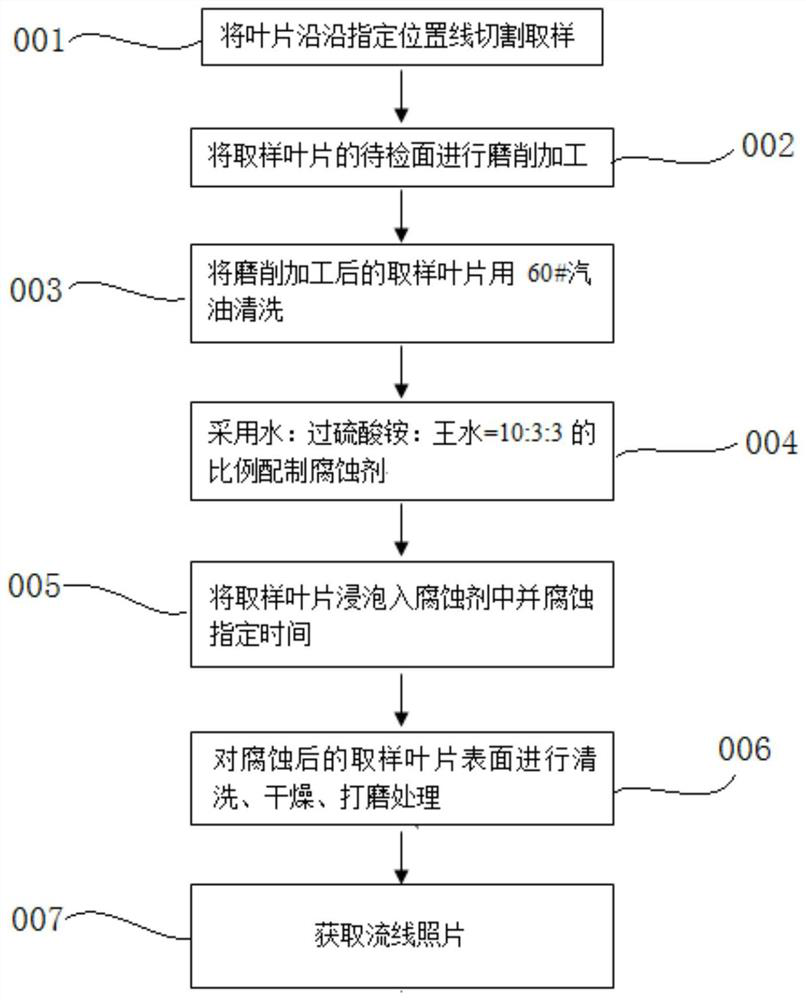

[0035] Embodiment 1: as figure 1 As shown, this embodiment provides a method for inspecting the streamline of a stainless steel die forging blade, which includes the following steps:

[0036] S001: Cut and sample the blade along the line at the specified position, which is usually selected according to the technical requirements of the blade.

[0037] S002: Grinding the surface of the sampling blade to be inspected; specifically, in the step of grinding the surface of the sampling blade to be inspected, the wet grinding method with cooling liquid is adopted. The finish needs to be 0.8.

[0038] S003: Clean the sampling blade after grinding with 60# gasoline.

[0039] S004: Use water: ammonium persulfate: aqua regia = 10:3:3 to prepare the etchant; it should be noted that there is no sequence restriction on this step and the above three steps. In some cases, this step can be carried out completely. The first step is to mix the corrosive agent well, and then sample and grind ...

Embodiment 2

[0043] Embodiment 2: This embodiment provides a method for making a corrosion solution for streamline inspection of blades of stainless steel die forgings. The corrosion agent is prepared in a ratio of water: ammonium persulfate: aqua regia=10:3:3. The specific process for configuring the corrosion agent is as follows:

[0044] Pour the specified volume of water into the test container first;

[0045] Add ammonium persulfate in proportion according to the water capacity, and stir with a glass rod while adding;

[0046] After the ammonium persulfate is completely dissolved in the water, add aqua regia in proportion according to the water capacity, and stir with a glass rod while adding.

[0047] Specifically, for example, 2000ml of water + 600g of ammonium persulfate + 600ml of aqua regia can be used to prepare the corrosion solution. First pour 2000ml of water into the test container, then slowly add the weighed ammonium persulfate, and stir with a glass rod while adding. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com