Method for detecting adhesive force of coating solution

A detection method and adhesion technology, which are applied in the measurement device, preparation and sampling of samples for testing, etc., to achieve the effect of accurate judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

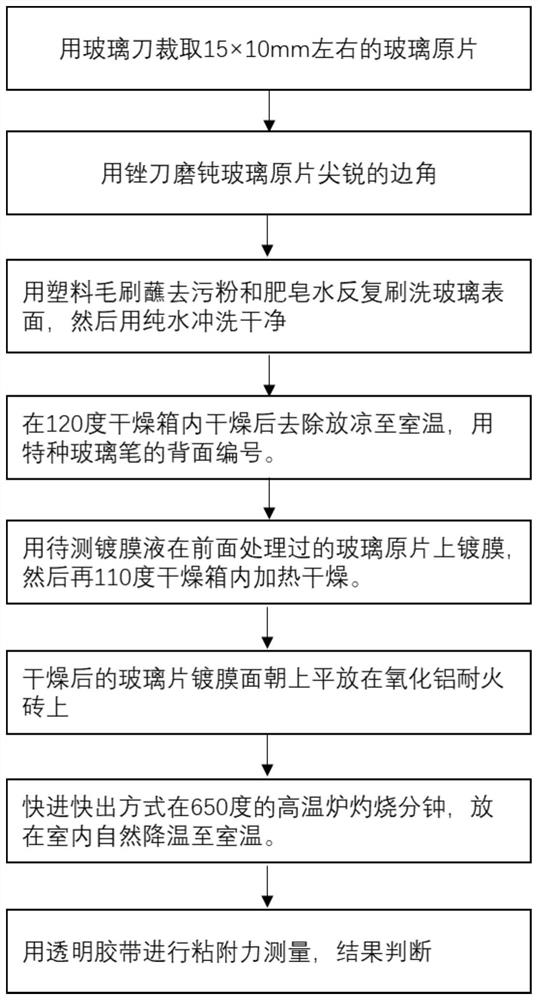

Image

Examples

Embodiment

[0024] S1) Processing of the original glass sheet:

[0025] First, use a glass knife to cut the original glass piece of 15×10mm, then use a file to blunt the sharp corners, use a plastic brush dipped in decontamination powder and soapy water to repeatedly rinse the glass surface, and then rinse it with pure water. After drying in a drying oven at ℃, take it out and let it cool to room temperature, and use a special glass pen to number the back.

[0026] S2) Coating of glass samples:

[0027] Use the coating solution to be tested to coat the previously treated original glass, and then dry it at 110°C

[0028] Heat and dry in the box, place the dried glass sheet (coated side up) on the alumina refractory brick (length, width, height 22×11.5×2.2mm), and use a long-handled shovel to scoop up the refractory brick and the glass on it The slices are quickly put into a high-temperature furnace set and heated to 650°C for 5 minutes, and then the alumina refractory bricks and the glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com