Dryer Control Method

A control method and technology for clothes dryers, which are applied to household clothes dryers, textiles, papermaking, washing devices, etc., and can solve problems affecting the working performance of clothes dryers and measurement deviations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

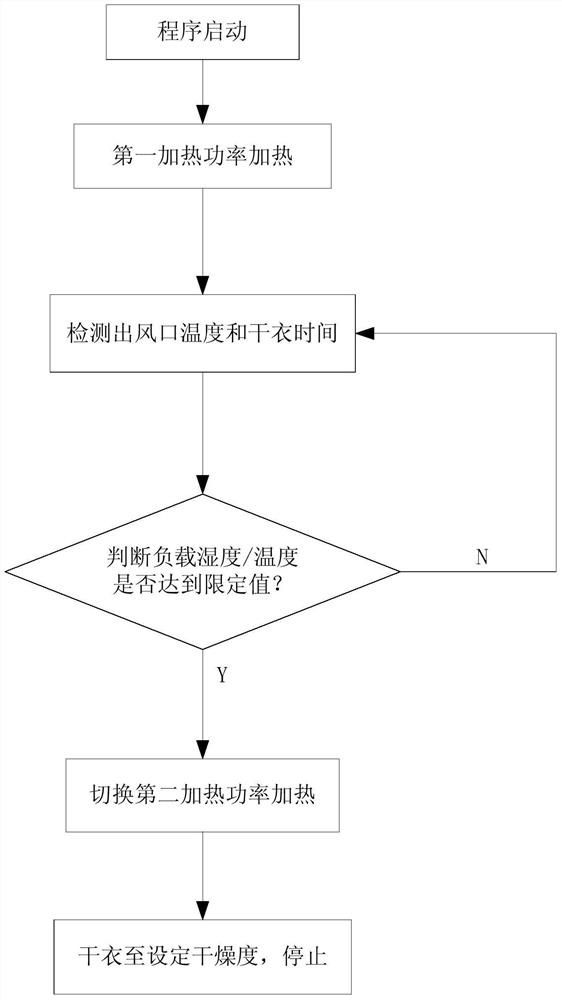

[0039] like figure 2 As shown, in the dryer control method of the present invention, the dryer heating device is provided with a first heating power and a second heating power, the first heating power is greater than the second heating power, and the wet clothes are put into the dryer , select the drying grade, start the program, and start drying. The heating device first heats with the first heating power, detects the temperature of the air outlet and the drying time in real time, and judges whether the moisture content of the load reaches the preset value according to the detected temperature of the air outlet and the drying time. The set limit value, when the limit value is reached, the control heating device is switched to the second heating power to continue heating for the set time, and then the clothes drying is completed.

[0040] Or, the difference from the above solution is: judge whether the load temperature reaches the preset limit value according to the detected ...

Embodiment 2

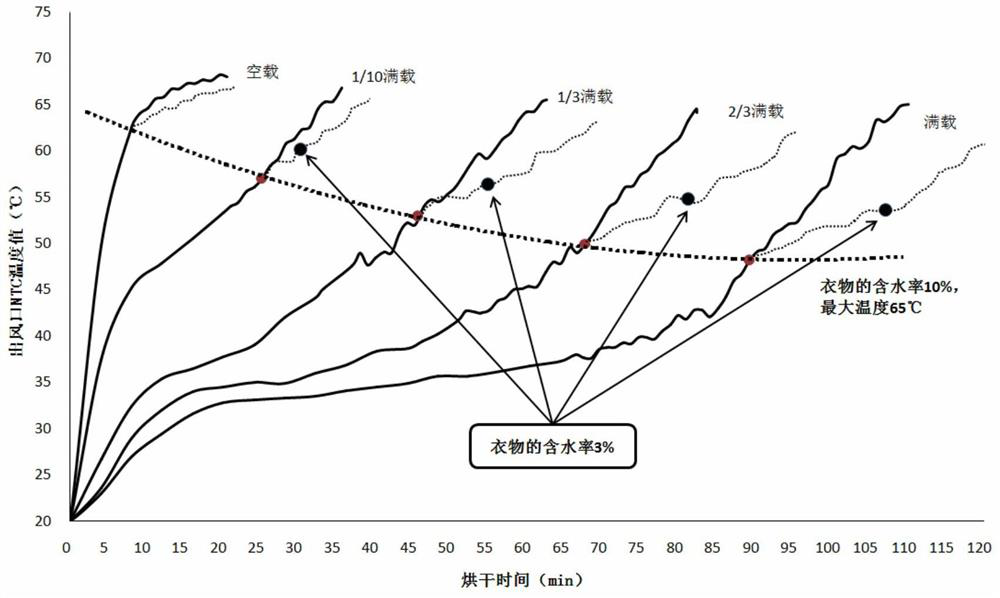

[0042] figure 1 In order to obtain the fitting function curve of the moisture content of the clothes and the maximum temperature of the corresponding clothes through data analysis, the fitting function is T=At 2 +Bt+C, T is the temperature value of the air outlet, t is the drying time, and A, B, and C are constants. For example, when the moisture content of the load is 10%, the fitting function is T=A 1 t 2 +B 1 t+C 1 , the corresponding maximum load temperature is 65°C. During the drying process, when the detected temperature value of the air outlet and the drying time satisfy the fitting function T=A 1 t 2 +B 1 t+C 1 At this time, control the heating power of the heating device to reduce from 1600W to 1200W, and then continue to dry for a period of time. 1 t, D 1 is a constant, and t is the running time when the moisture content of the clothes reaches 10%, that is, the working time when the heating power is 1600W, until the final moisture content of the clothes reac...

Embodiment 3

[0045] This embodiment is different from the above-mentioned embodiment 2. Different drying grades of clothes dryers are equipped with a fitting function T=At with the same load moisture content of 40%. 2 +Bt+C, when the temperature value of the detected air outlet and the drying time satisfy the fitting function T=At 2 When +Bt+C, control the heating power of the heating device to reduce from 1600W to 1400W, and then continue to dry for a period of time D 3 t, t is the running time when the moisture content of the clothes reaches 40%, reaching the set drying level, the final moisture content of the clothes is 25%, or drying for a period of time with a heating power of 1400W D 4 t, to reach another set drying level, the final moisture content of the clothes is 15%, or, the heating power is 1400W to dry for a period of time D 4 t, reaching another set drying level, the final moisture content of the clothes is 10%. The way is to adjust the working time of the second heating po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com