Steam Turbine Fault Diagnosis Method Based on Feature Selection of Stationary and Nonstationary Vibration Signals

A technology of non-stationary signals and vibration signals, which is applied in pattern recognition in signals, engine testing, computer components, etc., can solve problems that have not yet been reported in research, to avoid interference, accurately locate and repair faults, and ensure The effect of safe and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples.

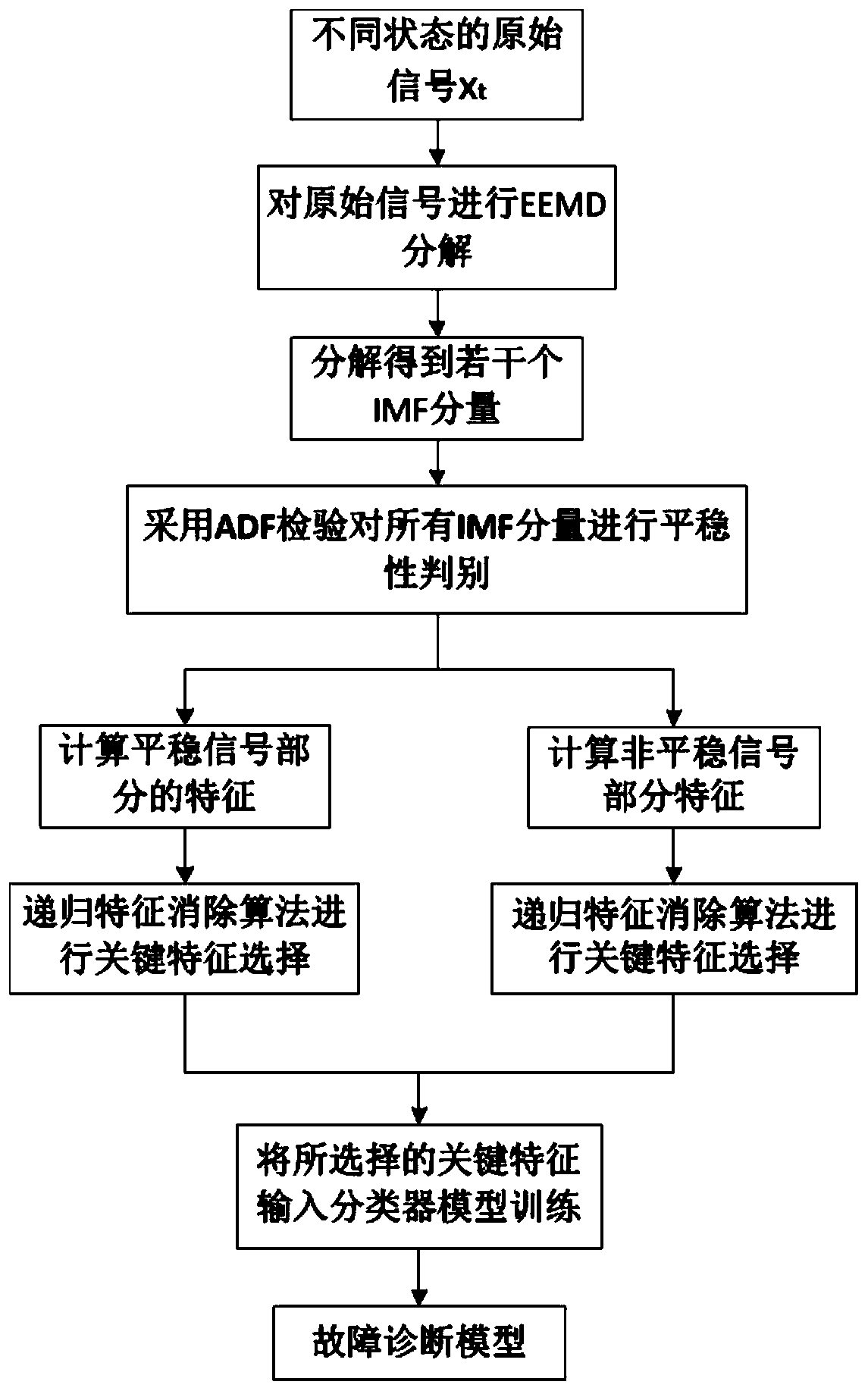

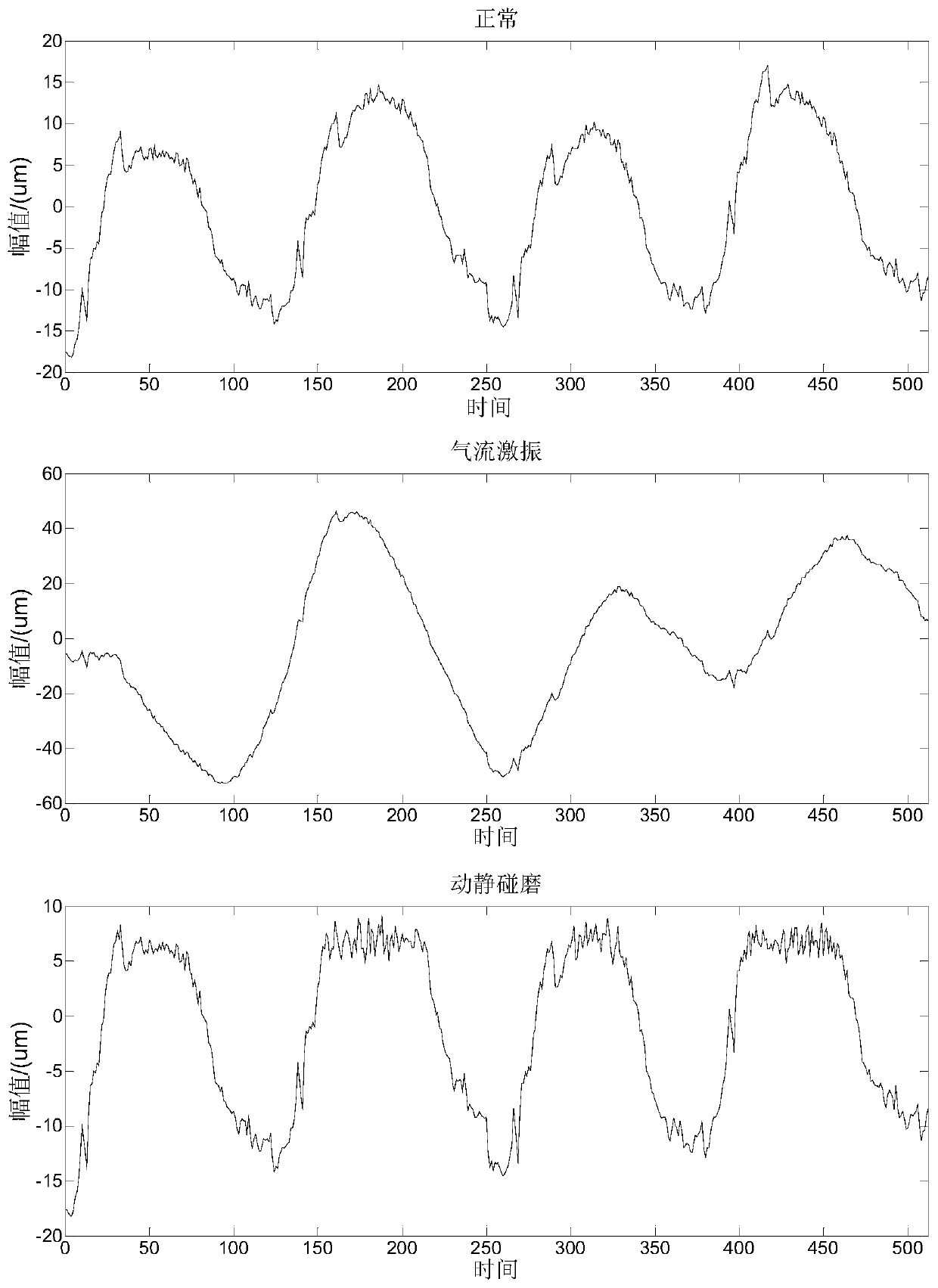

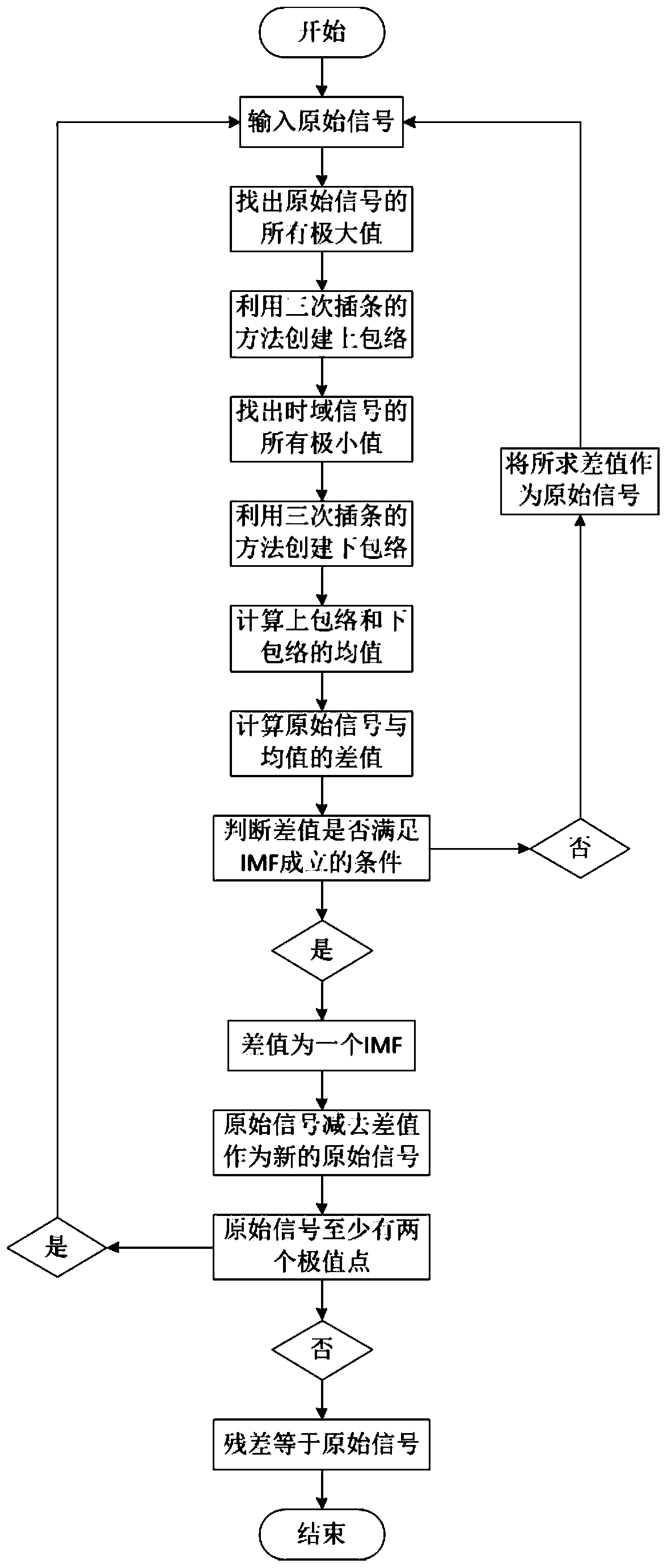

[0041] The vibration signal of the main engine of the steam turbine unit in thermal power generation is nonlinear and non-stationary. The original signal contains a lot of noise. It is difficult to directly extract information from the original signal. The present invention takes the two typical faults of the airflow excitation fault and the dynamic and static friction fault that occur in the main engine of a steam turbine unit in a thermal power plant as examples, as shown in figure 1 As shown, the method of the present invention is described in detail. Such as figure 2 As shown, the airflow excitation fault is specifically manifested as the vibration of the shaft system increases, and the low-frequency component of the signal increases; the dynamic and static friction friction fault specifically manifests as the "peak" of the vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com