A kind of high-efficiency electrocatalyst composite material and its preparation method and application

An electrocatalyst and composite material technology, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve problems such as unsatisfactory catalytic activity, loss of electrocatalytic activity of support materials, uniform dispersion of nano-alloy particles, etc., to avoid rapid attenuation, High stability, stable dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

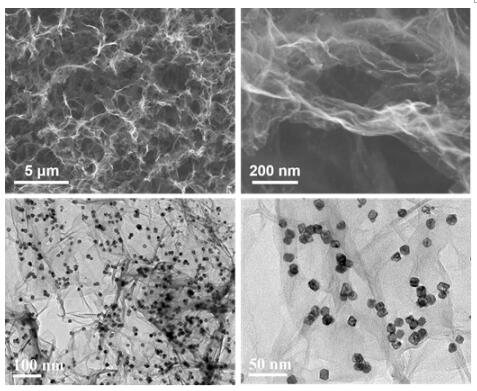

[0059] Example 1 Synthesis of Hierarchically Porous Noble Metal Nanoalloy / Graphene Airgel Composite Catalyst

[0060] 1. Prepare the multi-level porous noble metal pore nano-alloy / graphene airgel composite catalyst by the following method, comprising the following steps:

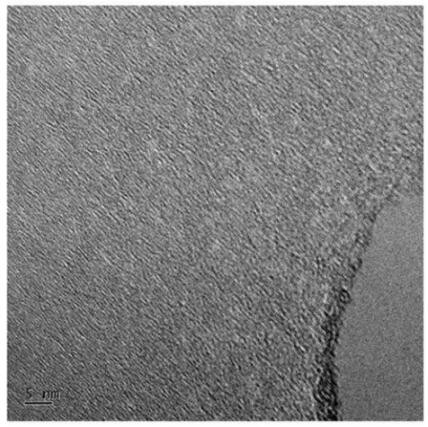

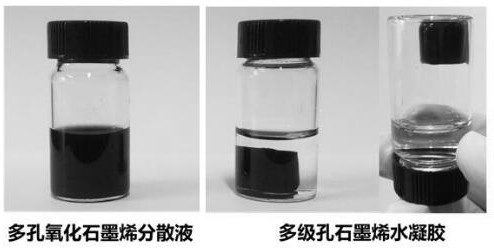

[0061] (1) Synthesis of graphene oxide lamellar dispersion with rich mesoporous structure on the surface:

[0062] Synthesis of graphene oxide dispersion: Disperse 5 g of natural flake graphite, 5 g of sodium nitrate and 15 g of potassium permanganate in 150 mL of concentrated sulfuric acid, stir and react for 10 h, heat up to 95 °C for 0.5 h, then let stand , pour off the supernatant, centrifuge and wash the precipitate several times until it becomes neutral, and then peel it off into solvent water by ultrasonic dispersion for 15 min, and a uniformly dispersed graphene oxide dispersion can be obtained;

[0063] Etching and pore forming treatment: take 100 mL of 5 mg / mL graphene oxide solution, add 2.5 g of...

Embodiment 2

[0076] Example 2 Synthesis of Hierarchically Porous Noble Metal Nanoalloy / Graphene Airgel Composite Catalyst

[0077] 1. Preparation method

[0078] Other conditions of the preparation method of present embodiment catalyst are with embodiment 1, and difference is:

[0079] (1) The reducing agent is sodium borohydride;

[0080] (2) The condition of hydrothermal reaction is: 180℃ hydrothermal reaction for 6 h.

[0081] 2. Results

[0082] (1) In this example, a metal nanoparticle alloy / graphene composite airgel with a hierarchical porous structure was obtained, and its specific surface area was as high as 510 m 2 / g, has a rich pore structure, and the loading of porous noble metal nanoalloys is as high as 20 wt%.

[0083] (3) In this example, a metal nanoalloy / graphene composite airgel with a hierarchical porous structure was obtained. Taking the decomposition of formic acid as an example, its catalytic activity per unit mass and unit area is as high as 520 mA / mg and 3.55 mA...

Embodiment 3

[0085] Example 3 Synthesis of Hierarchically Porous Noble Metal Nanoalloy / Graphene Airgel Composite Catalyst

[0086] 1. Preparation method

[0087] Other conditions of the preparation method of present embodiment catalyst are with embodiment 2, and difference is:

[0088] (1) The reducing agent is ascorbic acid;

[0089] (2) The condition of hydrothermal reaction is: 180℃ hydrothermal reaction for 12 h.

[0090] 2. Results

[0091] (1) In this example, a metal nanoparticle alloy / graphene composite airgel with a hierarchical porous structure was obtained, and its specific surface area was as high as 450 m 2 / g, has a rich pore structure, and the loading of porous noble metal nanoalloys is as high as 20 wt%.

[0092] (3) In this example, a metal nanoalloy / graphene composite airgel with a hierarchical porous structure was obtained. Taking the decomposition of formic acid as an example, its catalytic activity per unit mass and unit area is as high as 510 mA / mg and 3.55 mA / cm re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com