Pollutant treatment device utilizing foam dielectric barrier discharge plasma

A technology of dielectric barrier discharge and pollutant treatment, which is applied in the field of pollutant treatment, can solve problems such as differences in application effects, achieve low operating costs, avoid spark discharge, and improve energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

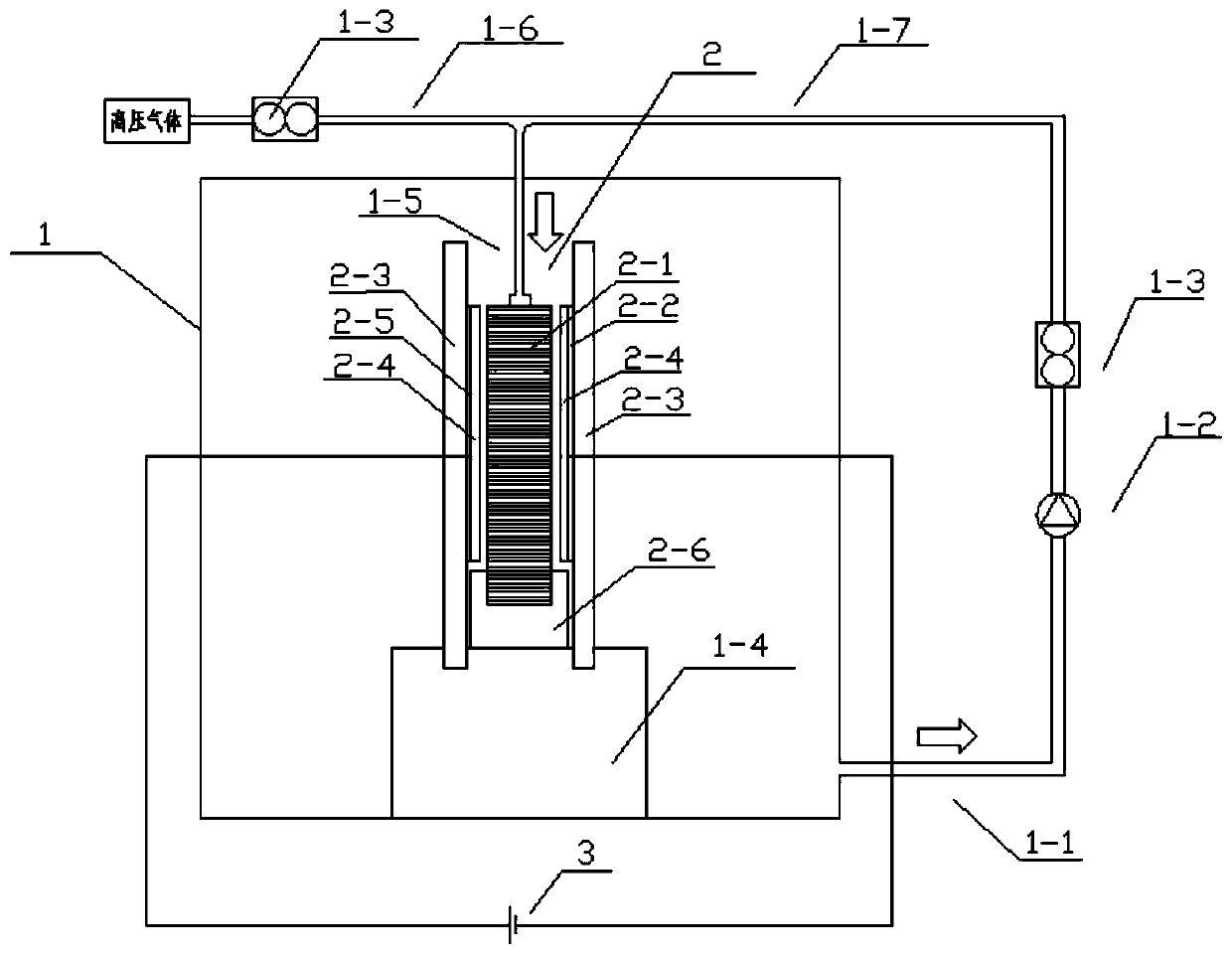

[0029] Example: see Figure 1-2 , a foam type dielectric barrier discharge plasma pollutant treatment device, which includes a water tank 1, a discharge assembly 2 and a high voltage power supply 3.

[0030] The water inlet (1-5) of the water tank 1 is connected with the water inlet pipe (1-7) and the air inlet pipe (1-6), and the water outlet of the water tank 1 is connected with the water outlet pipe (1-1).

[0031] The discharge assembly 2 includes a high-voltage electrode (2-2), an insulating medium 1 (2-3), an insulating medium 2 (2-4), an aeration disc (2-1) and a grounding electrode (2-5).

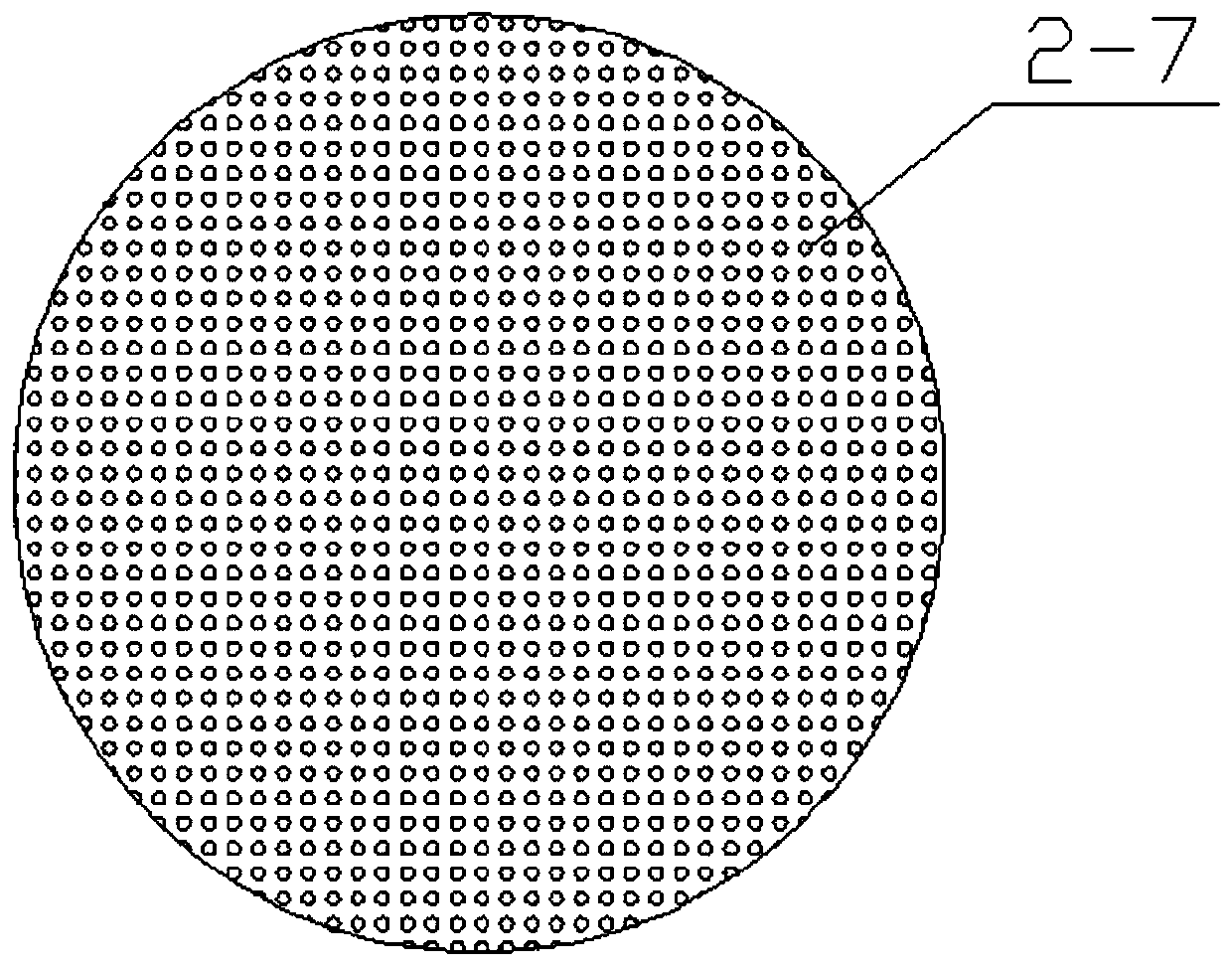

[0032] The high-voltage electrode (2-2) is closely attached between the insulating medium 1 (2-3) and the insulating medium 2 (2-4), and the ground electrode (2-5) is closely attached to the insulating medium 1 ( 2-3) and the insulating medium 2 (2-4), between the two electrode assemblies, place an aeration disc, the surface of which is about 2mm away from the insulating medium 2 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com