Waste processing device based on two-sided micro-duct dielectric barrier discharge

A technology for dielectric barrier discharge and waste treatment, applied in gas treatment, light water/sewage treatment, membrane technology, etc. It can avoid the problems of slow mass transfer with the liquid phase, and achieve the effect of avoiding spark discharge, low cost and rapid diffusion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

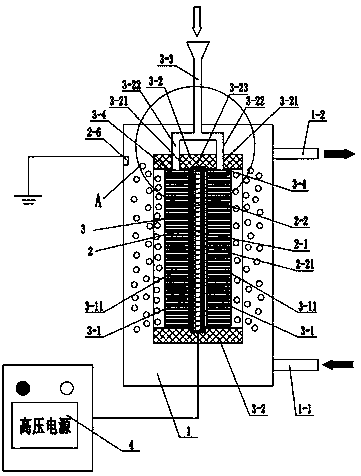

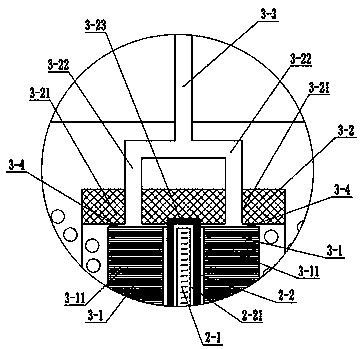

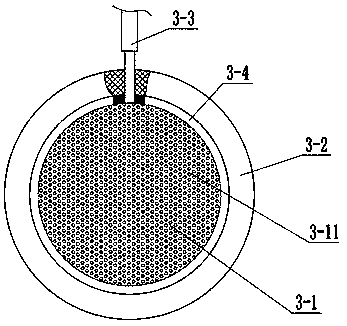

[0032] Example: see Figure 1-3 : A waste treatment device based on double-sided microchannel dielectric barrier discharge, which includes a water tank 1, a discharge assembly 2 and a microchannel assembly 3.

[0033] The water inlet of the water tank 1 is connected to the water inlet pipe 1-1, and the water outlet of the water tank 1 is connected to the water outlet pipe 1-2.

[0034] The water tank 1 is grounded or a ground electrode 2-6 is arranged in the water tank 1 . Specifically, when the water tank 1 is made of conductive material, the water tank 1 may be grounded. And when the water tank 1 is non-conductive, the ground electrode 2-6 is arranged in the water tank 1.

[0035]The water tank 1 is grounded or a ground electrode 2-6 is arranged in the water tank 1; the discharge assembly 2 includes a high voltage electrode 2-1 and an insulating medium 2-2, and the insulating medium 2-2 is arranged in the water tank 1, The insulating medium 2-2 has a high-voltage electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com