Insulation and heat conduction heat radiation structure based on ceramic chip

A technology of insulating heat conduction and heat dissipation structure, which is applied in the direction of semiconductor devices, semiconductor/solid-state device components, electrical components, etc., can solve the problems of low dielectric strength, IGBT enhanced dielectric strength, etc., and achieve the effect of enhancing insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

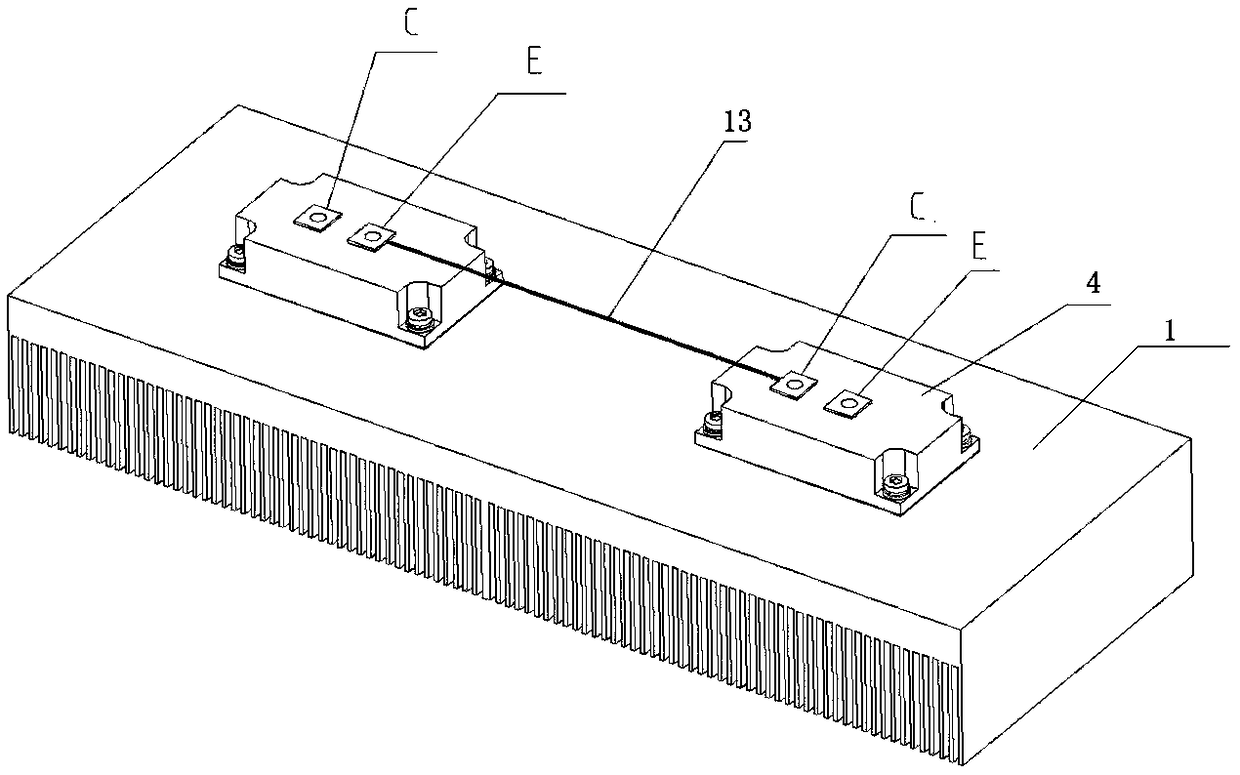

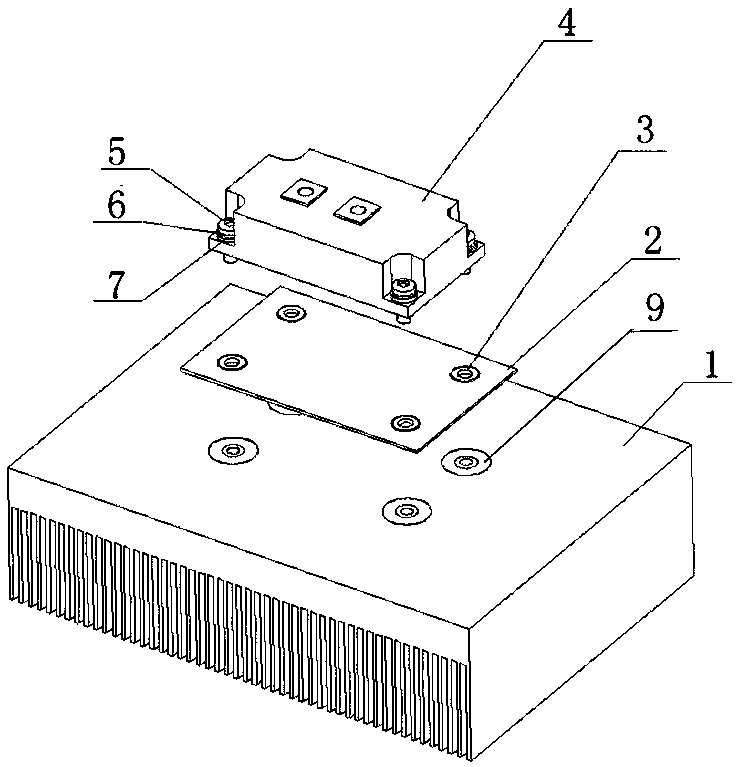

[0032] Such as Figure 3-Figure 6 As shown, an insulating, heat-conducting and heat-dissipating structure based on a ceramic sheet includes a radiator 1, on which an IGBT package 4 is fixed, and an insulating fixture 9; There is a ceramic sheet 2; the insulating fixing member 9 fixes the IGBT package 4 and the ceramic sheet 2 to the heat sink 1 in sequence.

[0033] The IGBT package 4 includes an IGBT substrate 10 disposed at the bottom. The surface of the IGBT substrate 10 in contact with the ceramic sheet 2 is an arcuate surface 14 , and the middle of the arcuate surface 14 protrudes toward the ceramic sheet 2 . In order to increase heat transfer efficiency, a thermally conductive silica gel layer 8 is provided between the IGBT substrate 10 and the ceramic sheet 2 , and between the ceramic sheet 2 and the heat sink 1 .

[0034] The insulating fixing part 9 includes a groove provided on the radiator 1, and a metal screw sleeve 1-3 is arranged in the groove, and a structural ...

Embodiment 3

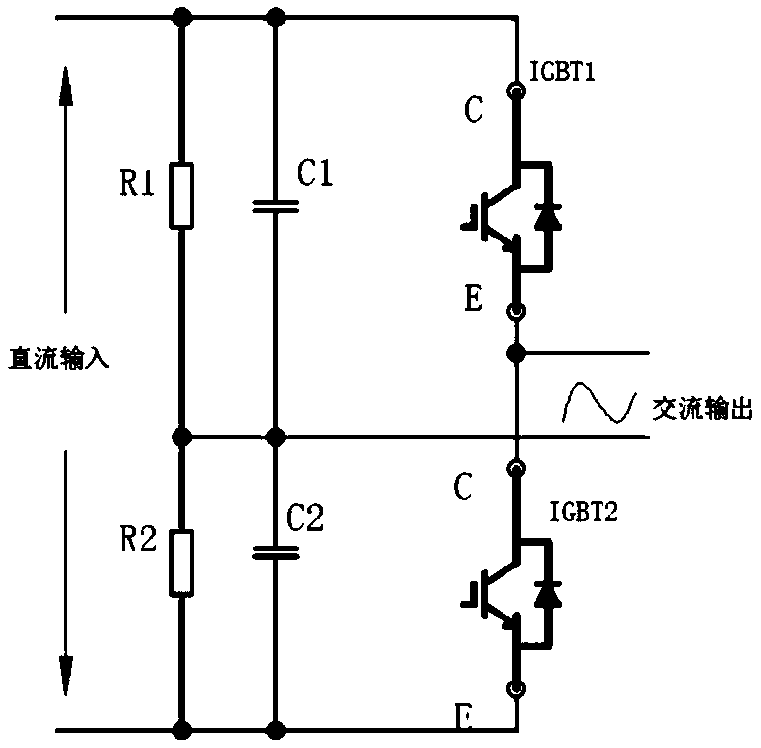

[0041] On the basis of Example 2, the IGBT with a dielectric strength of 1700V is refitted and used, and the dielectric strength between its electrodes (C pole and E pole) and the radiator is determined by the structure of the device itself, that is to say, the electrodes ( The dielectric strength between C pole and E pole) and the radiator is equal to the dielectric strength between the electrodes (C pole and E pole) and the IGBT substrate, and its dielectric strength is generally 4kV. If it is applied to the dielectric strength requirement For lower occasions, there is no problem. However, for some occasions that require high dielectric strength, such as subway charger equipment, the dielectric strength is required to be 5.5kV, which will not be applicable.

[0042] In order to ensure that the IGBT with a dielectric strength of 1700V can meet the higher-level dielectric strength requirements, this solution adds a thermally conductive and insulating ceramic sheet between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com