Seasoning bag raw material film and production method

A raw material film and seasoning bag technology, which is applied to chemical instruments and methods, bags, sacks, etc., can solve the problems of poor heat insulation effect and poor safety of plastic films, so as to improve food safety, increase moisture-proof function, and reduce damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is further described in detail through specific implementation methods:

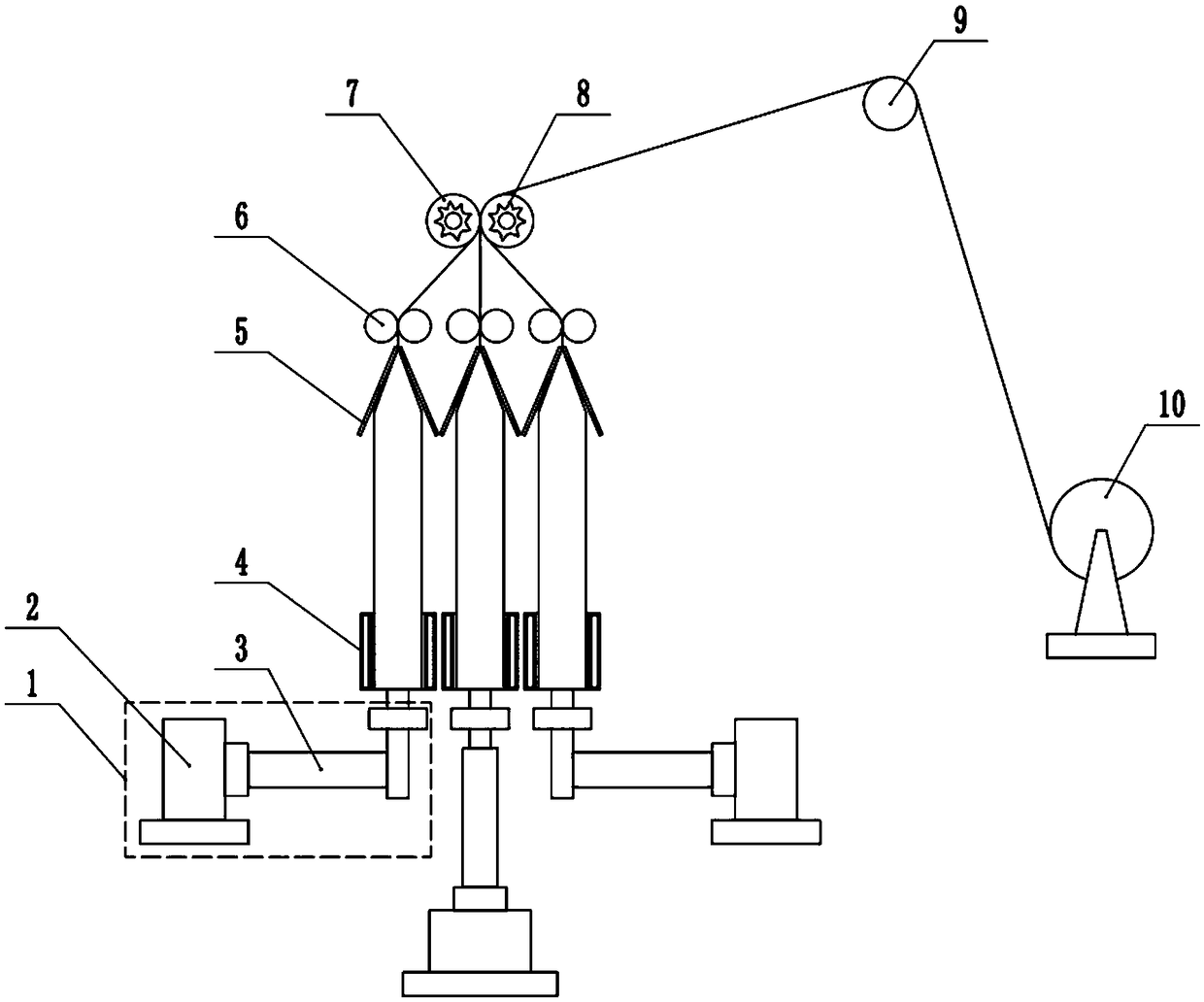

[0019] Instructions attached figure 1 The reference signs in include: extrusion device 1, material box 2, screw feeding pipe 3, cooling jacket 4, herringbone plate 5, traction roller 6, counter roller 7, heating wire 8, guide roller 9, receiving roller 10.

[0020] One, embodiment data are as shown in table 1:

[0021] Table 1

[0022] Example

filler

Antibacterial agents

Antioxidants

1

15

42

5

2

1

2

17

38

6

2

1

3

19

35

7

3

2

4

21

33

9

4

3

5

23

30

10

5

3

[0023] Taking Example 1 as an example, the seasoning bag raw material film formed in Table 1 is specifically described, including a base layer, a heat insulating layer and a moisture-proof layer, and a heat-insulating layer and a moisture-proof layer are arranged suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com