Automotive part transportation device capable of automatic route finding

A technology for auto parts and transportation devices, applied in the field of parts transportation, can solve the problems of slow manual handling and high intensity, and achieve the effects of reducing manual labor intensity, easy to use, and easy to automatically load and carry goods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

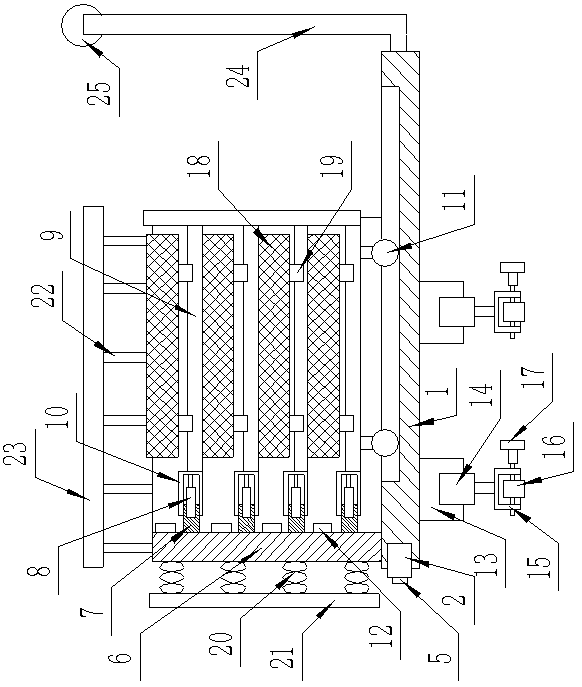

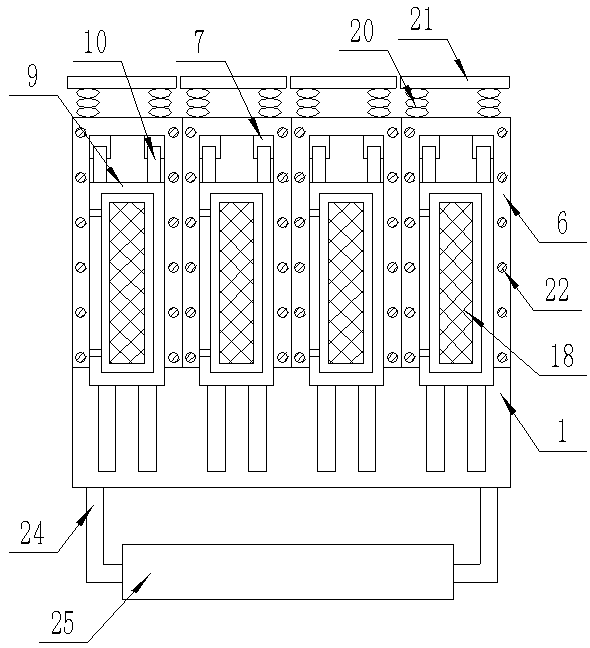

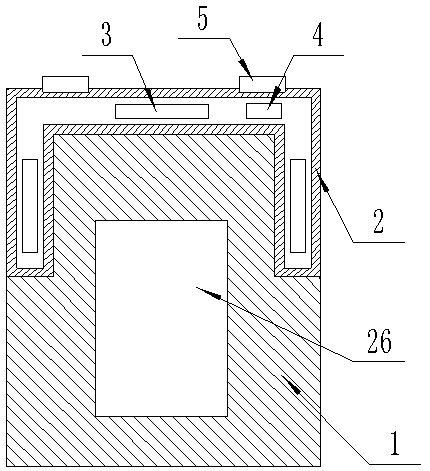

[0021] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, an auto parts transportation device capable of automatic pathfinding includes a carrying base 1, an automatic pathfinding transport mechanism is arranged on the upper surface of the carrying base 1, and an automatic pathfinding mechanism is arranged on the lower surface of the carrying base 1. The control movement mechanism connected with the transportation mechanism, the automatic pathfinding mechanism is mainly composed of folded grooves processed on the front surface of the bearing base 1 with both ends located on both sides of the bearing base 1, embedded in the folded grooves And the folding support box 2 that matches with the folding groove, the three ultrasonic emitting devices 3 that are arranged in the folding supporting box 2 and the sound wave pulse recovery device 4 that is connected with the three ultrasonic emitting devices 3, are embedde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com