Braking cooling system of main airplane wheel of multi-wheel-train airplane

A technology of cooling system and main engine wheel, applied in the direction of mechanical equipment, slack adjuster, brake type, etc., can solve the problems of low cooling efficiency, inability to meet the cooling requirements of multi-wheel train aircraft, and high maintenance cost, so as to reduce the aging speed and improve The effect of improving the overall service life and economic indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

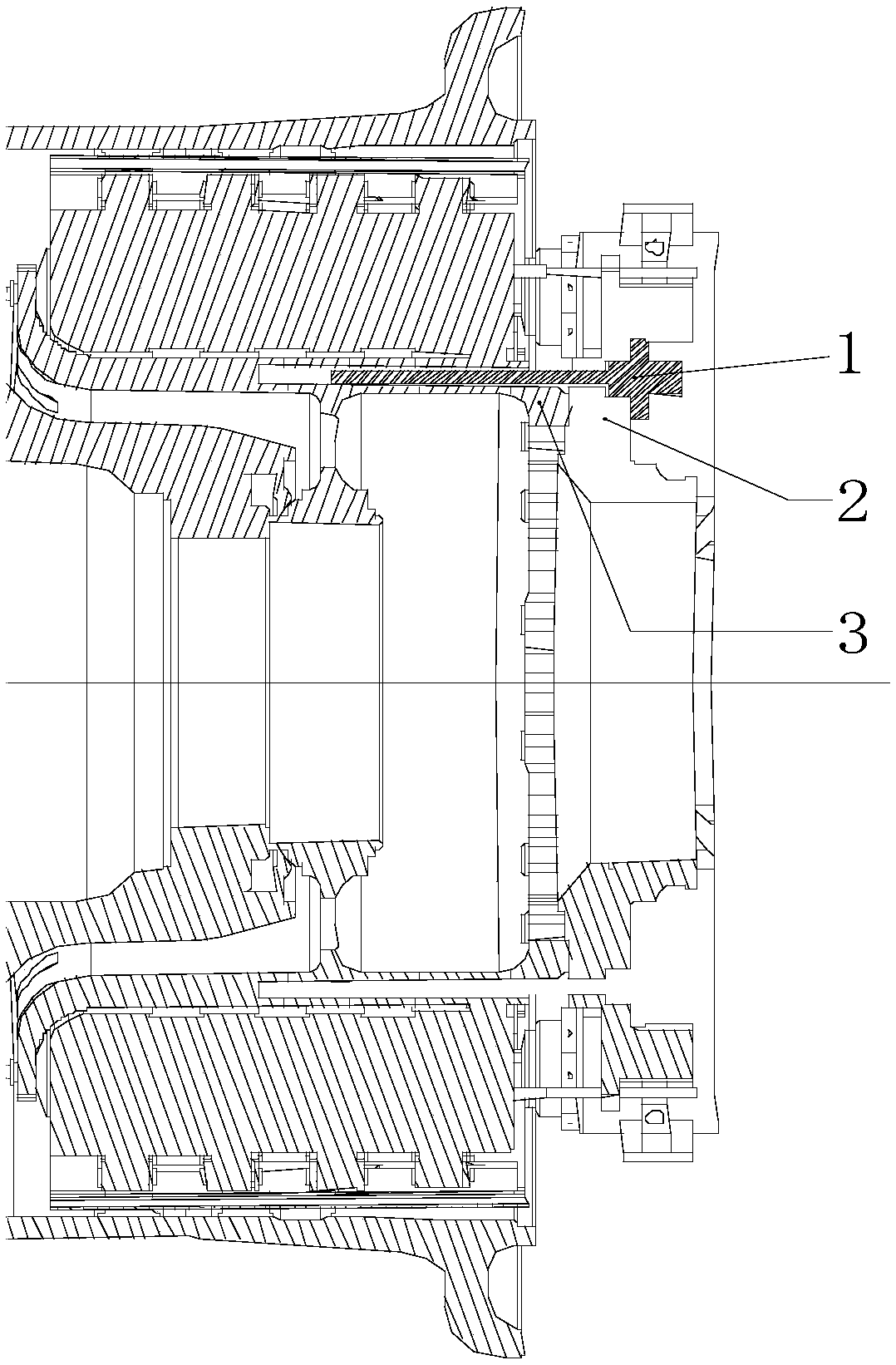

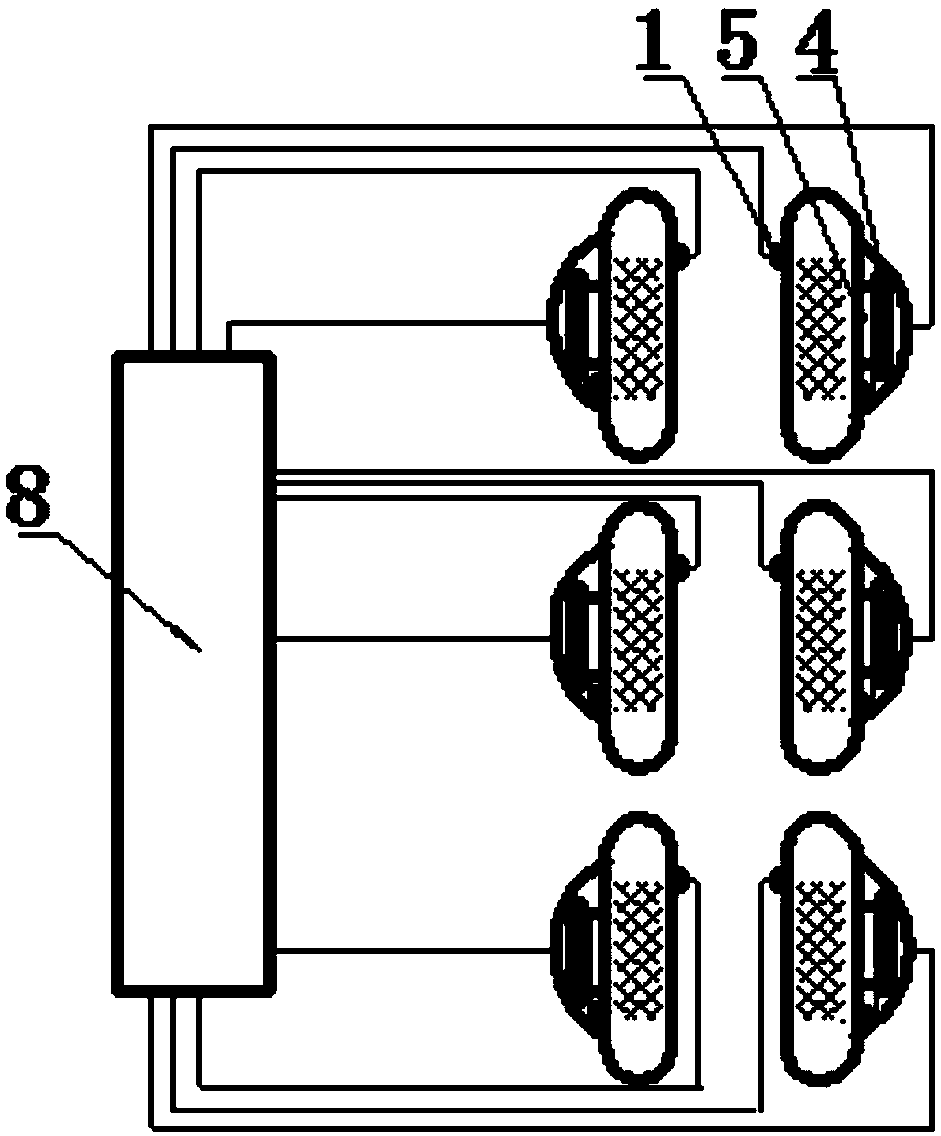

[0032] This embodiment is used for the brake cooling system of the main wheel of a certain type of six-wheel train aircraft.

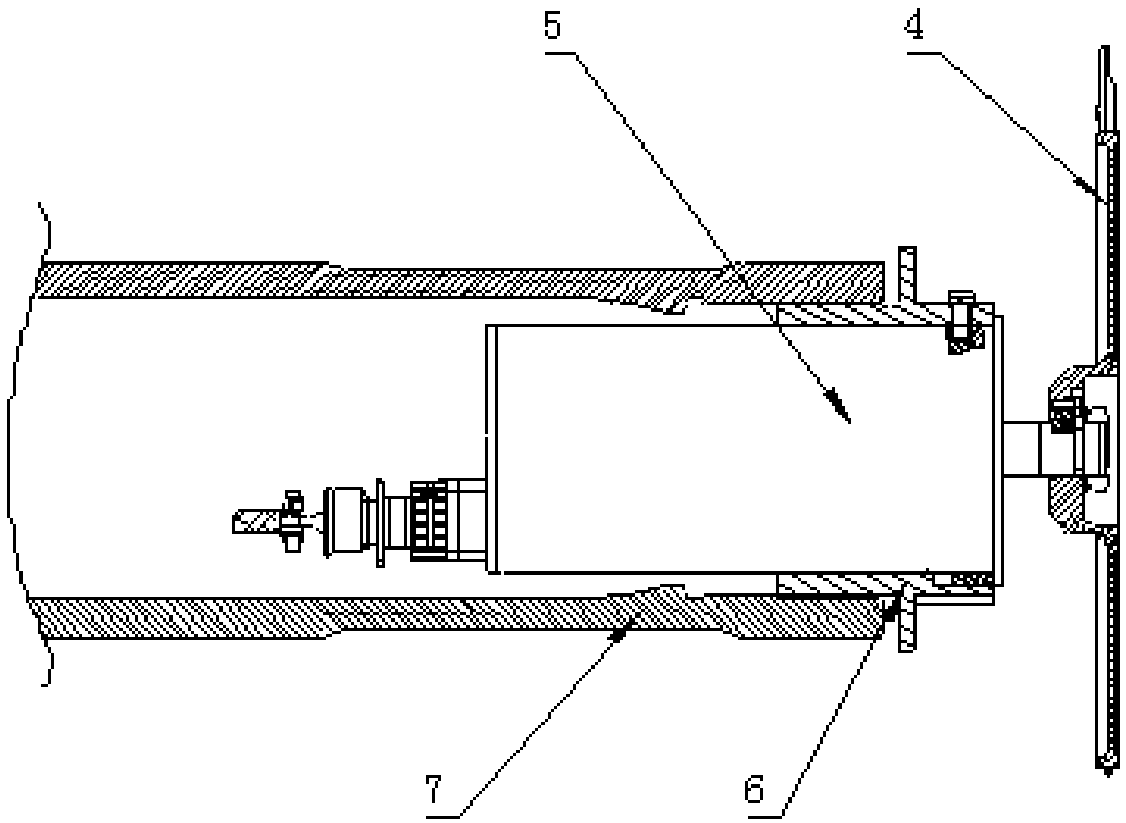

[0033] The brake cooling system is composed of six brake cooling assemblies and a temperature monitoring control box 8 . The brake cooling assembly includes a temperature sensor 1 , a fan 4 and a brake cooling motor 5 . Connect the signal input ends of the temperature sensors in the six brake cooling components to the temperature socket of the temperature monitoring control box through data cables, and connect the power input ends of the six brake cooling motors to the temperature detection through cables. The motor socket of the unit is connected.

[0034] In this embodiment, a set of brake cooling assemblies is taken as an example to describe its technical features in detail.

[0035] The brake cooling assembly includes a temperature sensor 1, a fan 4 and a brake cooling motor 5, wherein: the mounting plate of the temperature sensor 1 is packed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com