Ball screw drive of an electromechanical servo-assisted power steering system having integrated angular ball bearing and compensation for differing thermal expansion

An electromechanical servo and auxiliary power technology, which is applied in the transmission device, electric steering mechanism, power steering mechanism, etc., can solve problems such as inability to perform proper thermal compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

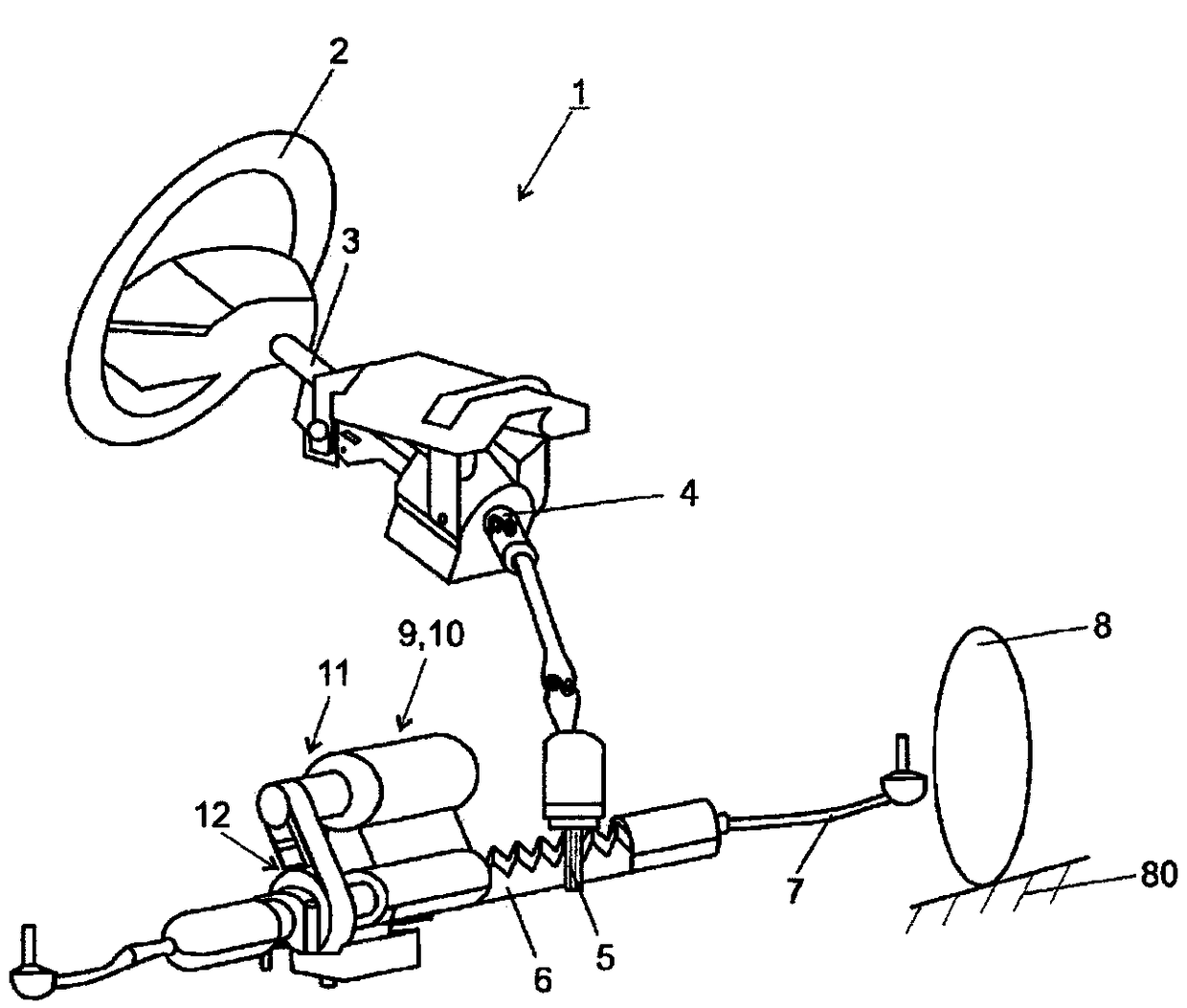

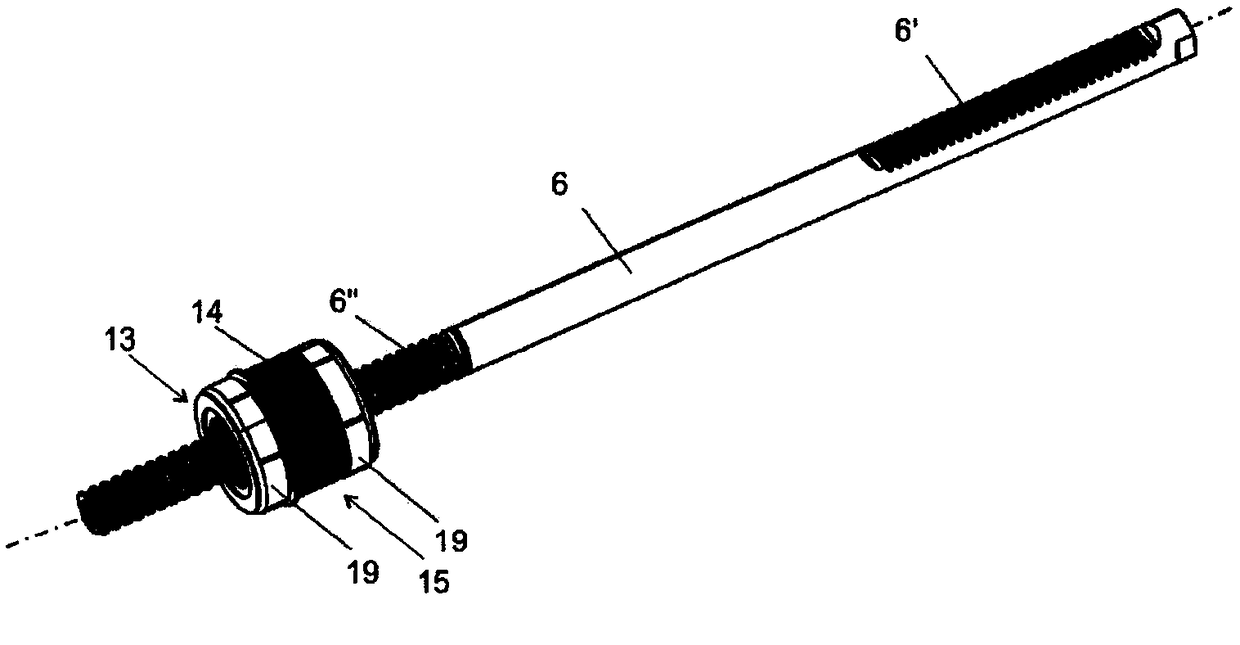

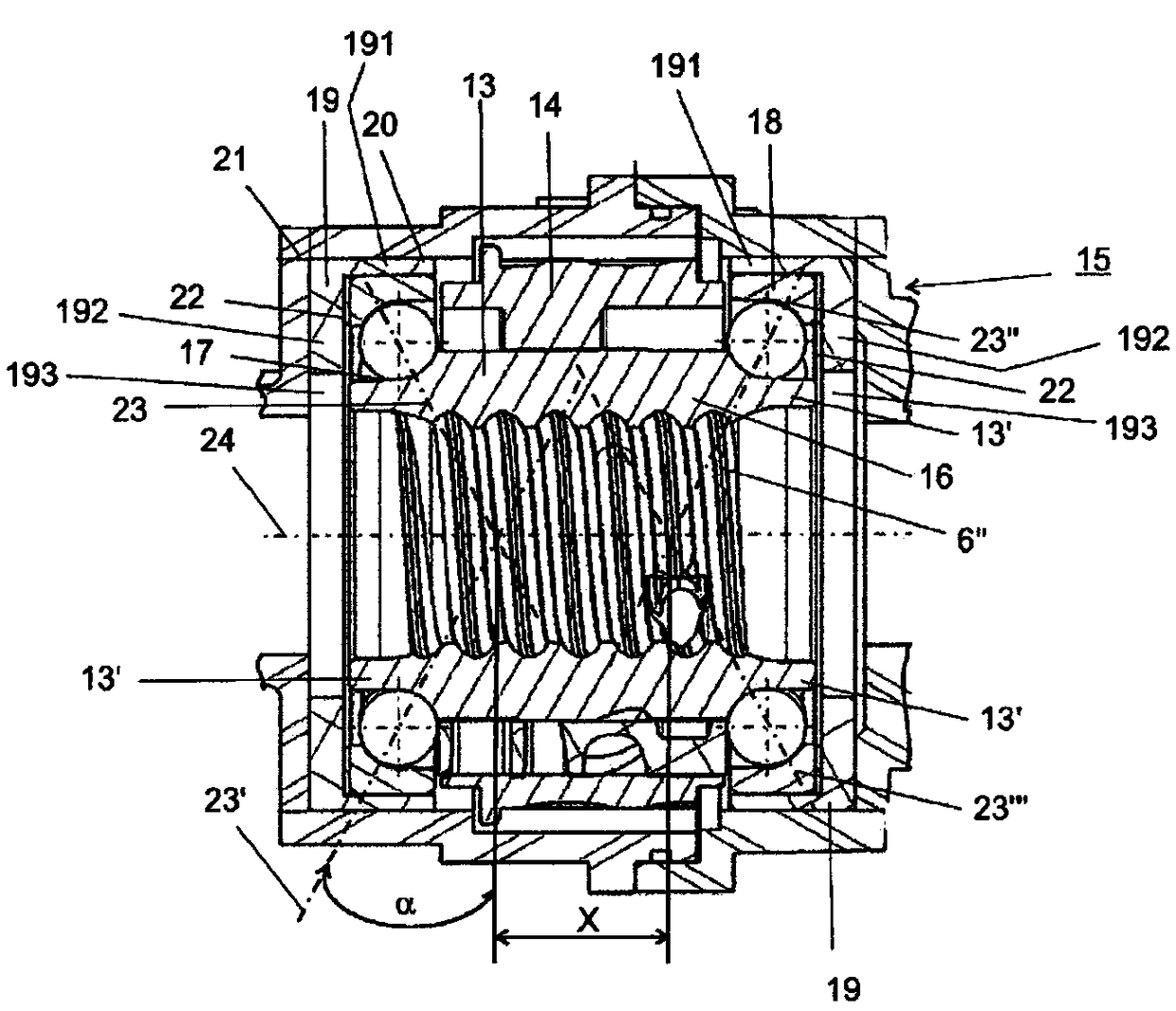

[0022] figure 1 The electromechanical motor vehicle steering system 1 is schematically shown with a steering wheel 2 coupled to the upper steering shaft 3 and the lower steering shaft 4 in a non-rotating manner. The upper steering shaft 3 is functionally connected to the lower steering shaft 4 by means of a torsion bar. The lower steering shaft 4 is connected to the pinion gear 5 in a non-rotating manner. The pinion 5 meshes with the toothed section 6'of the toothed rack 6 in a known manner. The toothed rack 6 is supported in the steering gear housing so as to be displaceable in the direction of its longitudinal axis. The toothed rack 6 is connected to the pull rod 7 at the free end of the toothed rack by means of a ball joint not shown. In each case, the tie rod 7 itself is connected to the articulated wheel 8 of the motor vehicle in a known manner by means of axle members. The rotation of the steering wheel 2 causes the longitudinal displacement of the toothed rack 6 via t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com