Automatic inclined lifting tea cooling device

A cooling device and lifting technology, applied in the direction of tea processing before extraction, can solve the problems of not reaching the appropriate temperature, occupying plant area, energy consumption of cooling equipment, etc., achieving better tea quality, reducing construction and maintenance costs, maintenance handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

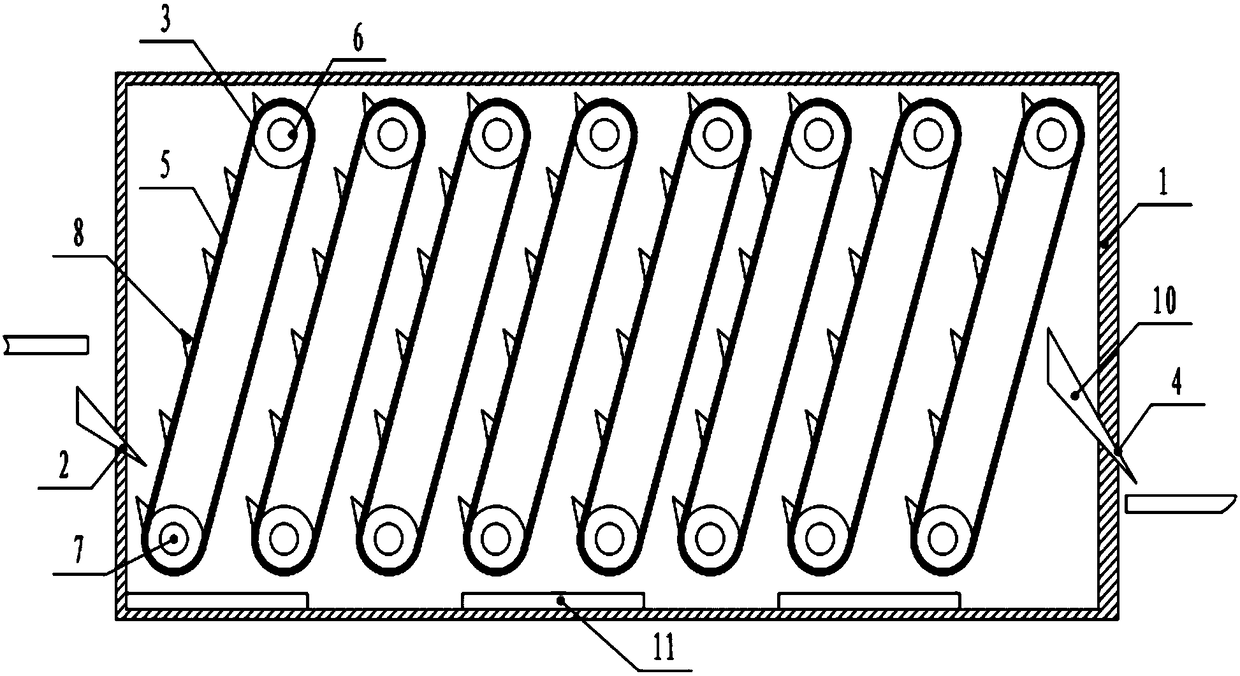

[0018] Embodiment 1: as figure 1 As shown, an automatic inclined lifting type tea cooling device includes a cooling chamber 1 connected with a cooling device 11, a feeding port 2 is provided on one side of the cooling chamber 1, and a plurality of lifting chambers arranged in sequence from left to right are arranged inside the cooling chamber 1. The machine 3 is provided with a discharge port 4 on the other side opposite to the feed port 2, and a plurality of elevators 3 can send the tea leaves transported by the feed port 2 out of the discharge port 4. The cooling device 11 includes a fan, a variable frequency motor and its controller.

[0019] Preferably, each hoist 3 is inclined to the right, and its structure includes a conveyor belt 5, a driving wheel 6 and a driven wheel 7, and the conveyor belt 5 is sleeved on the driving wheel 6 and the driven wheel 7, and a conveying hopper 8 is provided on its surface , the driving wheel 6 is installed on the top of the cooling cavi...

Embodiment 2

[0029] Embodiment 2: as figure 1 As shown, an automatic inclined lifting type tea cooling device includes a cooling chamber 1 connected with a cooling device 11, a feeding port 2 is provided on one side of the cooling chamber 1, and a plurality of lifting chambers arranged in sequence from left to right are arranged inside the cooling chamber 1. The machine 3 is provided with a discharge port 4 on the other side opposite to the feed port 2, and a plurality of elevators 3 can send the tea leaves transported by the feed port 2 out of the discharge port 4. The cooling device 11 includes a fan, a variable frequency motor and its controller.

[0030] Preferably, each hoist 3 is inclined to the right, and its structure includes a conveyor belt 5, a driving wheel 6 and a driven wheel 7, and the conveyor belt 5 is sleeved on the driving wheel 6 and the driven wheel 7, and a conveying hopper 8 is provided on its surface , the driving wheel 6 is installed on the top of the cooling cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com