A continuous preparation method of high-density polystyrene-based cation-exchange membrane

A cation exchange membrane, polystyrene technology, applied in chemical instruments and methods, membrane, membrane technology and other directions, can solve the problems of equipment, high technical requirements, high resistance, long production cycle, etc., to reduce adverse effects, shorten the process process, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

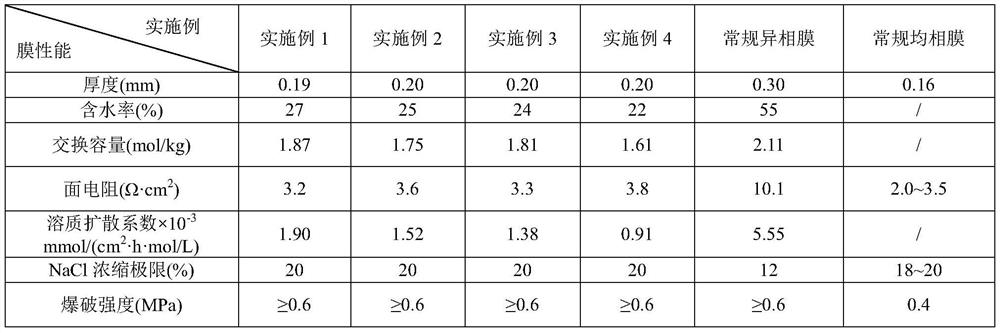

Examples

Embodiment 1

[0025] A method for continuously preparing high-density polystyrene-based cation-exchange membranes, comprising the following steps:

[0026] (1) At room temperature, add styrene, crosslinking agent divinylbenzene, initiator dibenzoyl peroxide and solvent N,N-dimethylformamide (2 times the quality of polyvinylidene fluoride) into the reactor, After stirring evenly, add polyvinylidene fluoride, and stir at 65°C until it dissolves into a homogeneous transparent styrene / polyvinylidene fluoride mixed solution, wherein the mass ratio of styrene to polyvinylidene fluoride is 1.0, and the mass of the crosslinking agent is 1% of the mass of styrene. 8%, the initiator mass is 1.5% of the styrene mass.

[0027](2) The mixed solution initiates polymerization at 80°C for 8 to 20 hours to obtain polystyrene / polyvinylidene fluoride jelly; extrude the jelly, precipitate and solidify, granulate, and dry to obtain polystyrene / polyvinylidene fluoride Ethylene white ball particles;

[0028] (3...

Embodiment 2

[0031] A method for continuously preparing high-density polystyrene-based cation-exchange membranes, comprising the following steps:

[0032] (1) At room temperature, add styrene, crosslinking agent divinylbenzene, initiator azobisisobutyronitrile and solvent N,N-dimethylacetamide (4 times the mass of polyvinylidene fluoride) into the reactor, After stirring evenly, add polyvinylidene fluoride, and stir at 65°C until it dissolves into a homogeneous transparent styrene / polyvinylidene fluoride mixed solution, wherein the mass ratio of styrene to polyvinylidene fluoride is 0.8, and the mass of the crosslinking agent is 1% of the mass of styrene. 10%, the initiator mass is 2.0% of the styrene mass.

[0033] (2) The mixed solution initiates polymerization at 85°C for 8-20 hours to obtain polystyrene / polyvinylidene fluoride jelly; extrude the jelly, precipitate and solidify, granulate, and dry to obtain polystyrene / polyvinylidene fluoride Ethylene white ball particles;

[0034] (3...

Embodiment 3

[0037] A method for continuously preparing high-density polystyrene-based cation-exchange membranes, comprising the following steps:

[0038] (1) At room temperature, mix styrene, crosslinking agent ethylene glycol dimethacrylate, initiator dibenzoyl peroxide and solvent N,N-dimethylformamide (6 times the quality of polyvinylidene fluoride) Add it into the reaction kettle, stir evenly, add polyvinylidene fluoride, stir at 70°C until it dissolves into a homogeneous transparent styrene / polyvinylidene fluoride mixed solution, wherein the mass ratio of styrene to polyvinylidene fluoride is 1.0, and the mass of crosslinking agent It is 11% of the mass of styrene, and the mass of the initiator is 3.0% of the mass of styrene.

[0039] (2) The mixed solution initiates polymerization at 90°C for 8-20 hours to obtain polystyrene / polyvinylidene fluoride jelly; extrude the jelly, precipitate and solidify, then granulate and dry to obtain polystyrene / polyvinylidene fluoride Ethylene white...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com