Multifunctional semi-automatic china bottle cleaning device

A semi-automatic and multi-functional technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of operation hazards, human and equipment influence, splashing water, etc., and achieves low machine cost, Easy operation and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

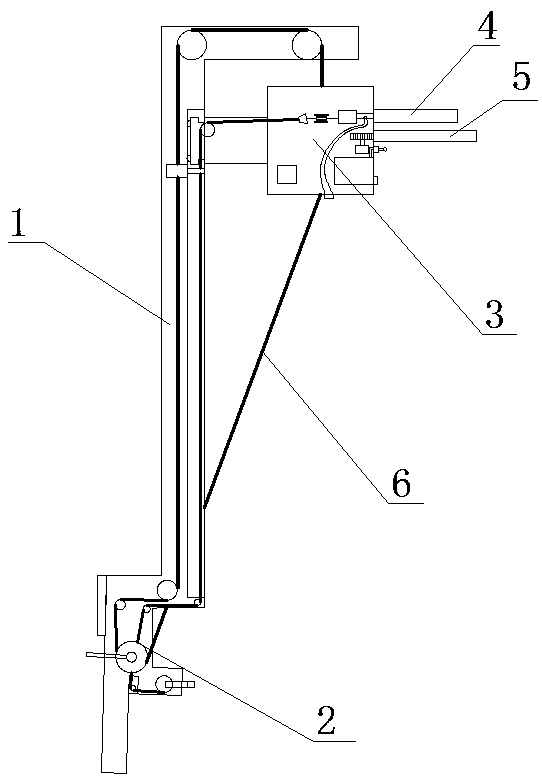

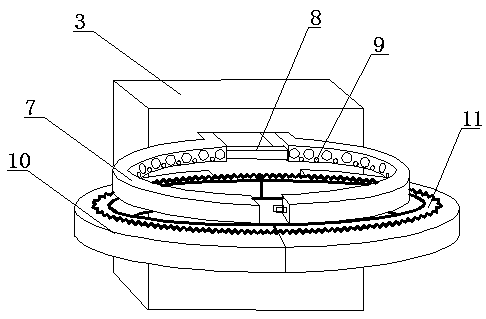

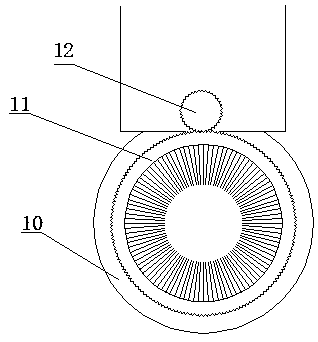

[0026] A multifunctional semi-automatic porcelain bottle cleaner, comprising an operating rod 1 and a cleaning device 3; the operating rod 1 is a bent rod, the top of the operating rod 1 is bent into a horizontal shape, and the shaft of the operating rod 1 is provided with a guide rail Groove 25, the bottom end of operating rod 1 is provided with operating handle 2 and control panel 28; Described operating handle 2 is fixed on the bottom of operating rod 1, and operating handle 2 is provided with rocking plate 30, adjusting wheel 35 and adjusting plate 34 The rocking plate 30 is provided with a rocking lever I29 and one end of the remote lever I29 protrudes from the outside of the operating handle 2; the adjusting wheel 35 is arranged below the shaking plate 30; the adjusting wheel 34 is arranged on the right side of the adjusting wheel 35 On the side, the adjusting disc 34 is also provided with a rocker II 33 and one end of the rocker II 33 protrudes from the outside of the op...

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 is that: the upper part of the guide rail groove 25 is also provided with an electric limit block 39, and the electric limit block 39 is composed of an electric push rod and a limit block.

Embodiment 3

[0032] The difference between this embodiment and Embodiment 1 is that: the rectangular opening on the connecting rod 71 of the fine cleaning ring 7 is also provided with a fixed brush 8, the fixed brush 8 is strip-shaped, and the fixed brush 8 wears The rectangular opening on the connecting rod of the fine cleaning ring 7 is fixed on the cleaning device 3 at both ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com