A Javelin Grinding Machine Tool

A grinding mechanism and machine tool technology, which is applied in the direction of grinding machines, grinding frames, grinding bed, etc., can solve the problems of poor standardization, high labor costs, and low production efficiency, so as to reduce stress, shorten the grinding process, and improve the quality of finished products. rate-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

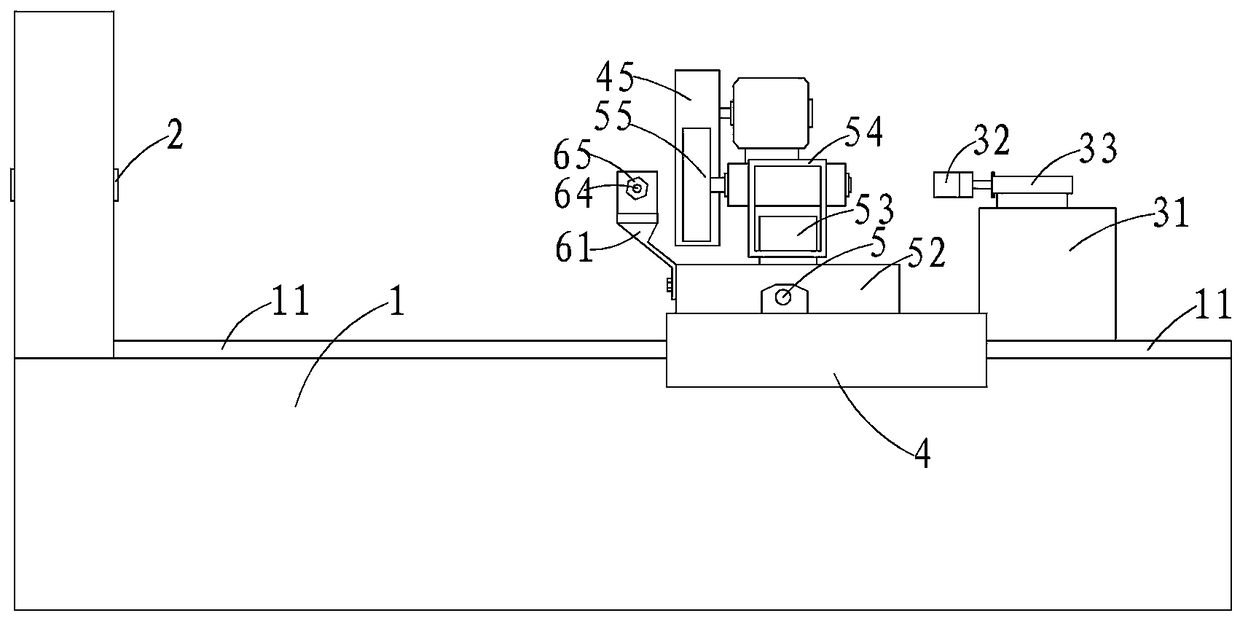

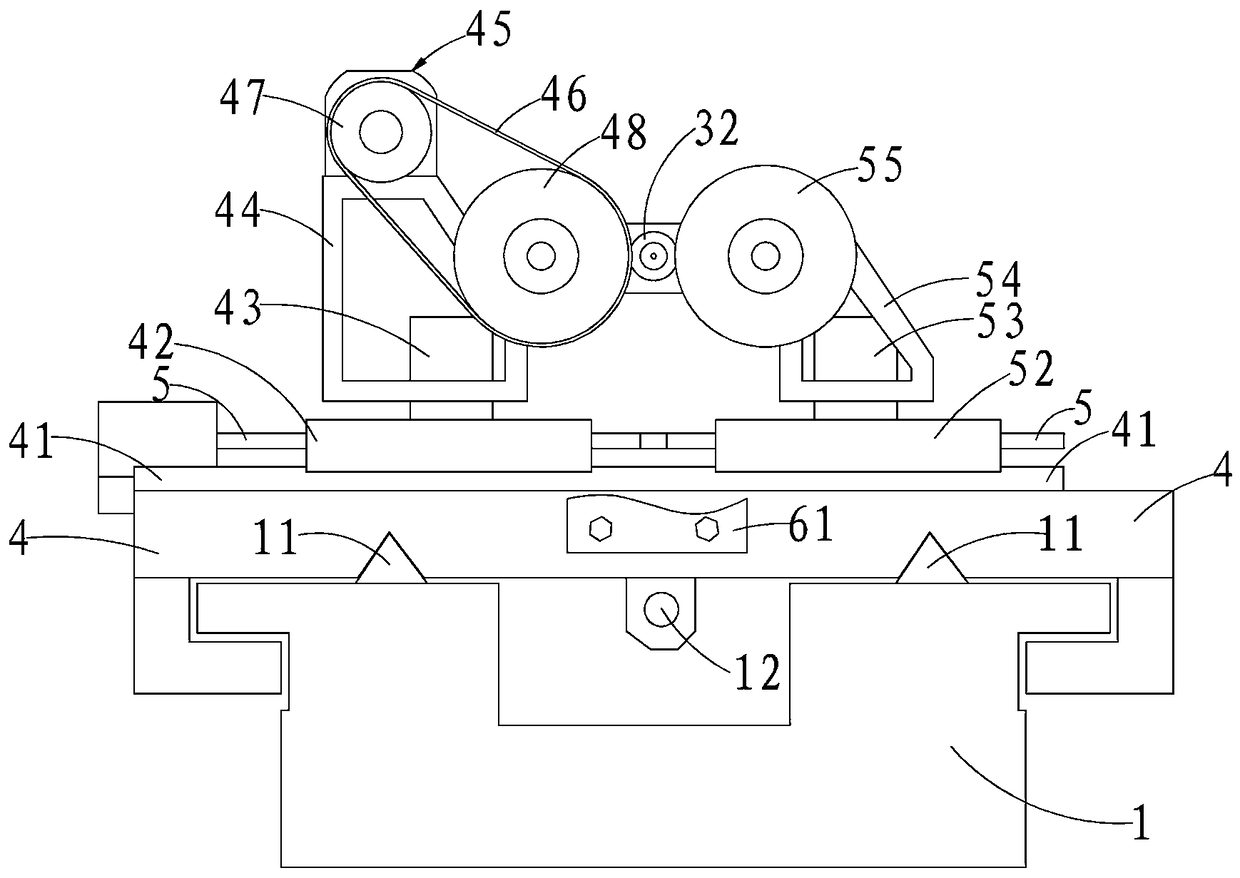

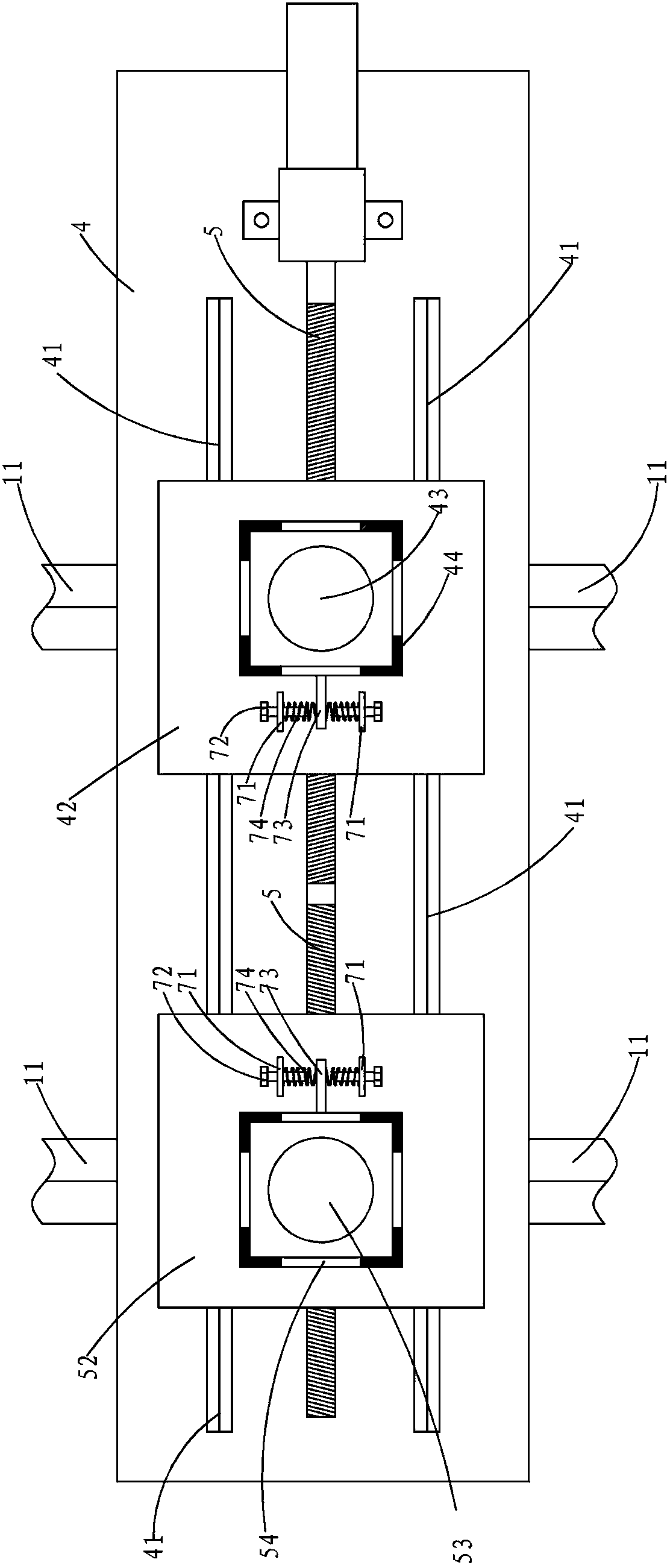

[0032] The following is attached Figure 1-5 The present invention is further described in detail.

[0033] as attached Figure 1-5 As shown, a javelin grinding machine tool includes a bed body 1, a rotating shaft 2 arranged at one end of the bed body 1, a jacking mechanism arranged at the other end of the bed body 1 corresponding to the rotating shaft 2 and arranged on the bed body through a slide rail 11. The grinding mechanism on the body 1, the grinding mechanism is located between the rotating shaft 2 and the clamping mechanism; a locking mechanism is arranged between the clamping mechanism and the bed body 1, and a There is an adjusting lead screw 12 that promotes the reciprocating movement of the grinding mechanism; the grinding mechanism includes a supporting plate 4 placed horizontally on the slide rail 11 and a grinding head and a tightening head that are arranged on the supporting plate 4 through the auxiliary slide rail 41, The grinding head and the top tightenin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com