Kitchen garbage processing bin

A technology of food waste and processing bins, which is applied in the direction of chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of breeding bacteria and mosquitoes, long composting treatment cycle, and difficult promotion, so as to improve the reliability of support Sexuality, easy to make full use of, avoid the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

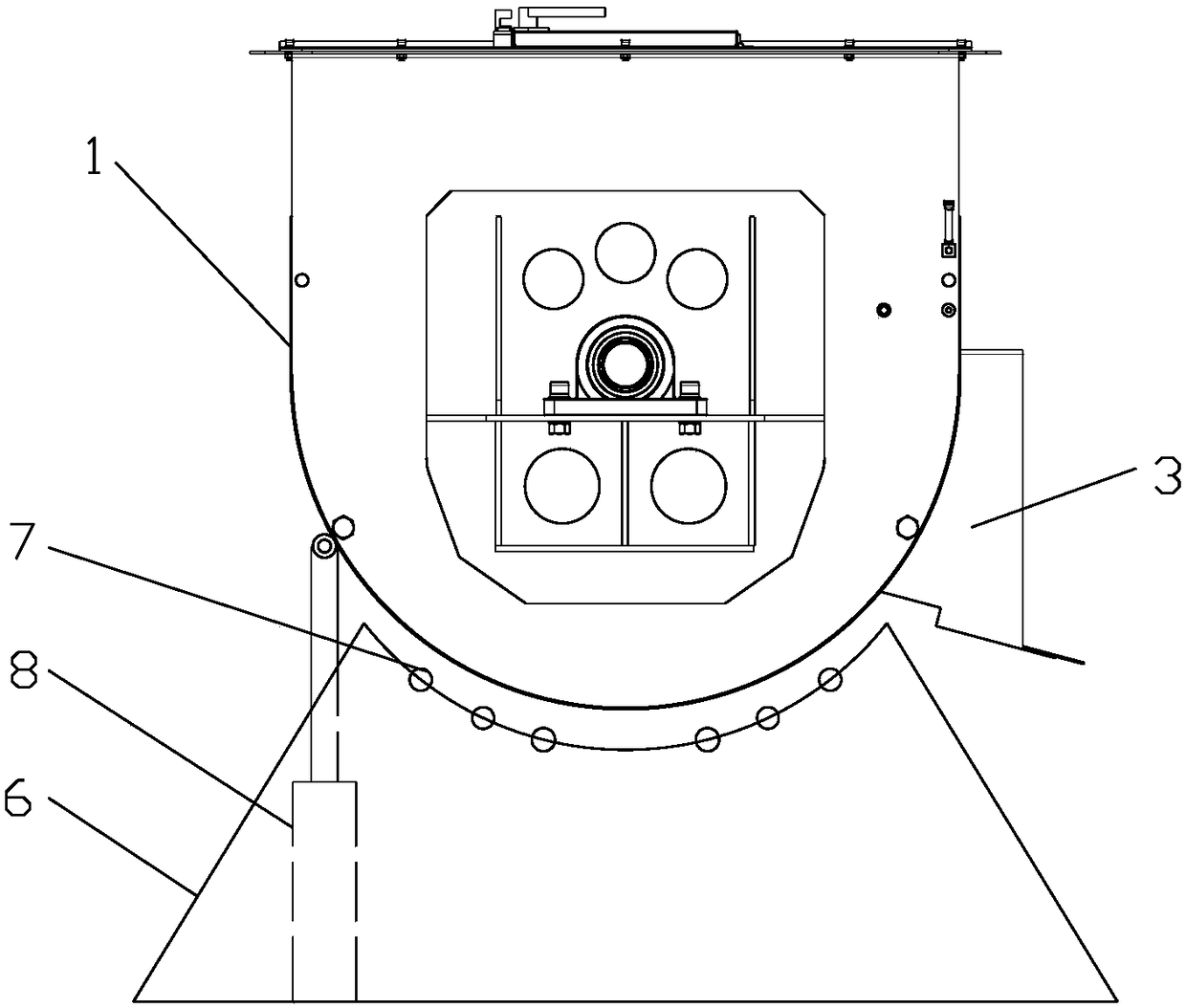

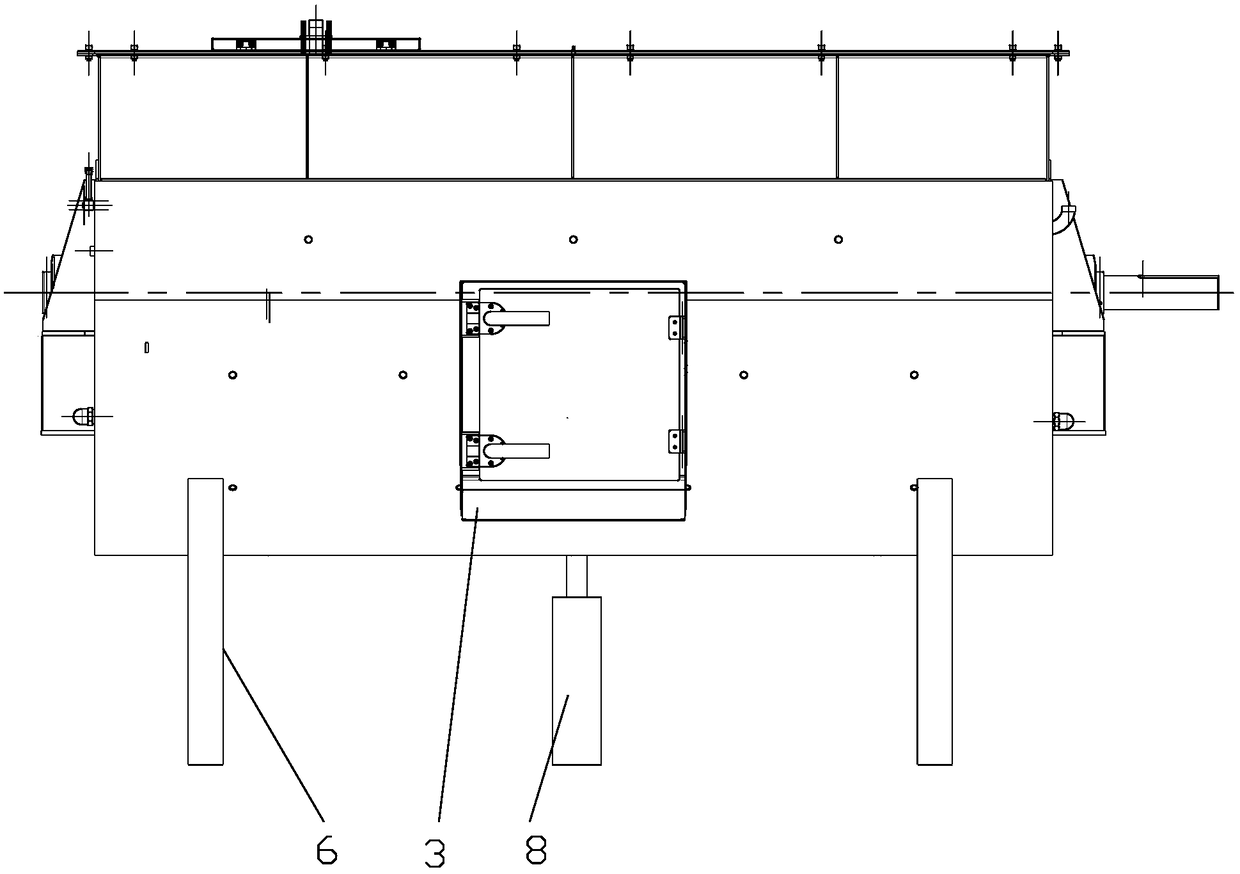

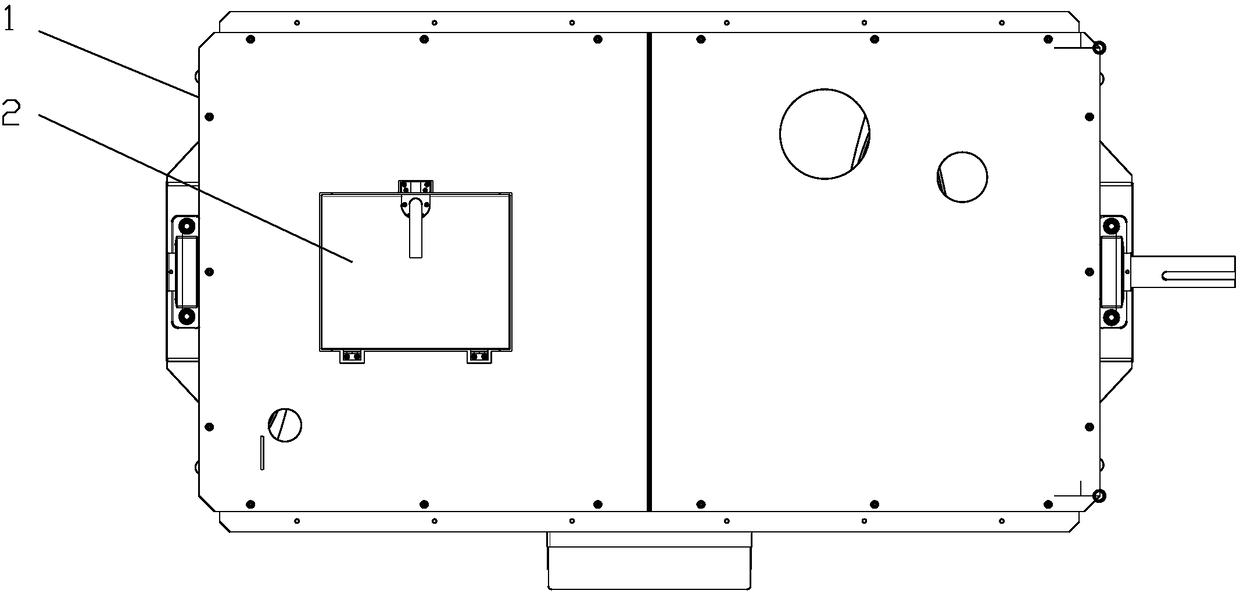

[0017] The present invention as Figure 1-5 As shown, it includes a bin body 1, the top of the bin body 1 is provided with a feed inlet 2, and the side is provided with a discharge port 3, and the bin body is provided with a stirring shaft 4, and the stirring shaft is provided with a stirring blade 5 ;

[0018] The warehouse body is arranged on a pair of parallel bases 6, the top surface of the base is arc-shaped, and the top surface of the base is provided with some balls 7;

[0019] A lifting mechanism 8 is provided below the bin body, and the lifting mechanism and the discharge port are respectively located on both sides of the bin body.

[0020] During work, food waste is put into the bin body from the feeding port, stirred by the stirring shaft, and bacteria agents can be put in for degradation and biochemical treatment, which is convenient for the full utilization of the waste and avoids polluting the environment; the bin body Placed on a pair of bases, at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com