Cross-shaped shaft grinding and clamping device

A technology of clamping device and cross shaft, applied in the direction of grinding drive device, grinding/polishing safety device, grinding frame, etc., can solve the problems of time-consuming and laborious, affecting work efficiency, etc., and achieve good cleaning effect and positioning effect. Good, the effect of improving the utilization rate of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is further described in detail through specific implementation methods:

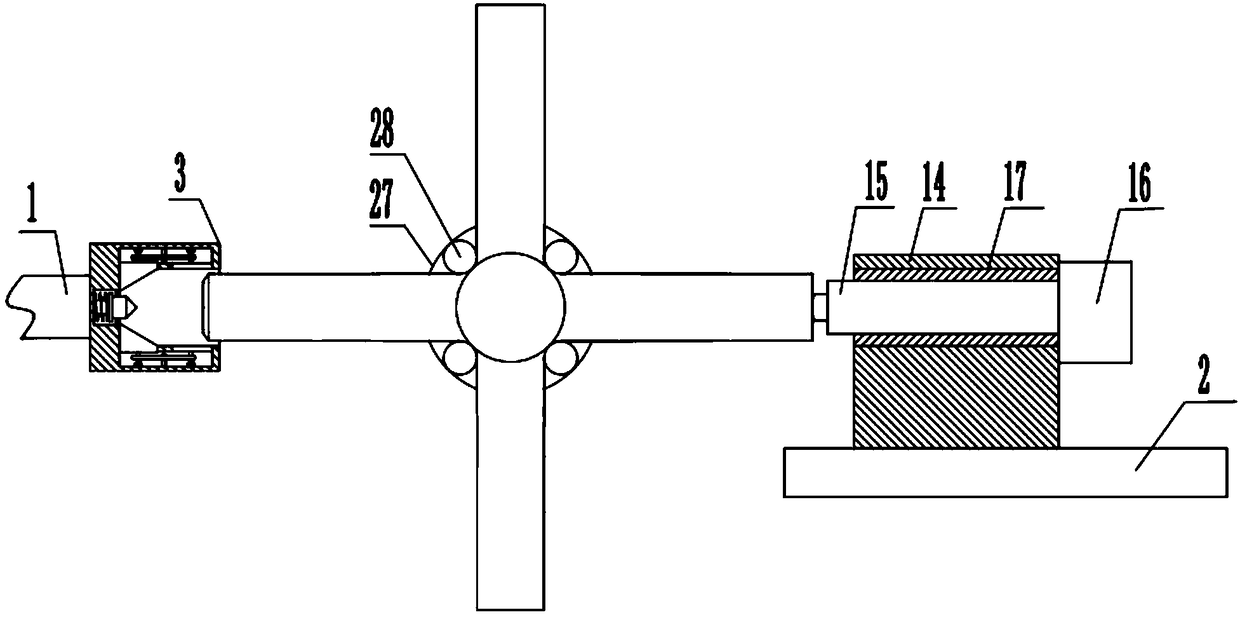

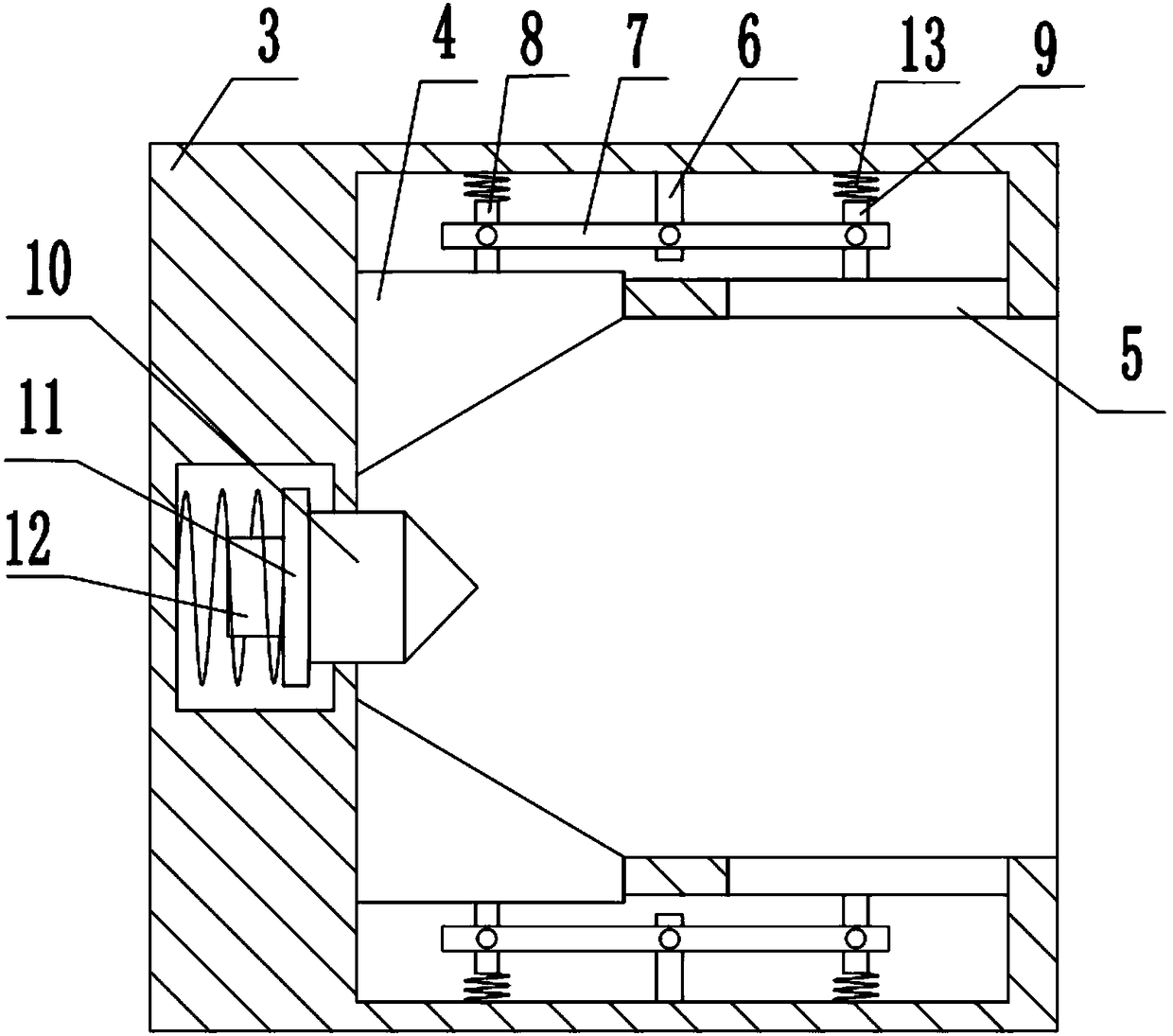

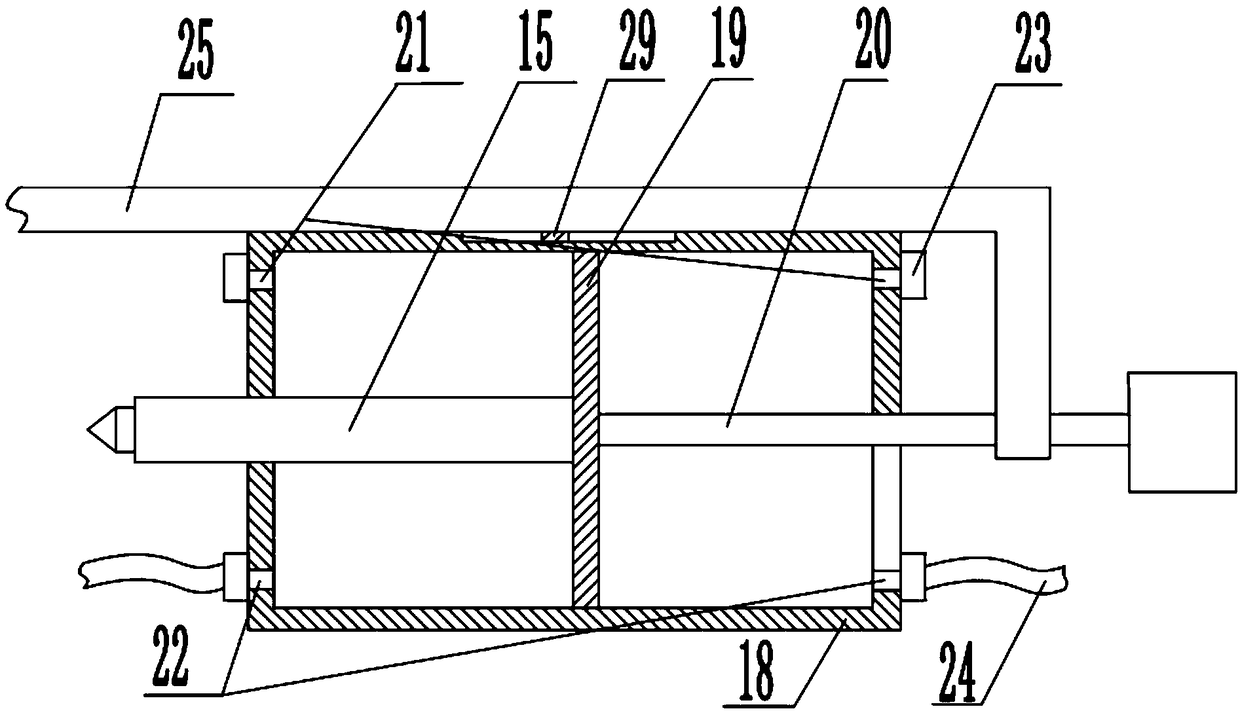

[0025] The reference signs in the drawings of the description include: machine tool spindle 1, machine tool guide rail 2, mounting seat 3, wedge block 4, clamping block 5, fixed rod 6, swing rod 7, first movable rod 8, second movable rod 9 , top 10, limit plate 11, positioning column 12, return spring 13, tailstock 14, pneumatic top 15, drive assembly 16, sliding sleeve 17, cylinder 18, piston plate 19, piston rod 20, air inlet 21, outlet Air port 22, one-way valve 23, air guide pipe 24, push rod 25, blade 26, rotating disk 27, fixed block 28, slide block 29, breach disc 30, rotating arm 31, cylindrical pin 32, sheave 33.

[0026] The embodiment is basically as attached figure 1 Shown: a cross-axis grinding and clamping device, including a machine tool spindle 1 and a machine tool guide rail 2, the machine tool spindle 1 is fixedly connected with a cross-axis clamping structure, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com