Piezoresistive type flexible tactile sensor with double-layer fastener type micro-bosses

A technology of tactile sensor and micro-protrusion, which is applied in the field of tactile sensor, can solve the problem of low flexibility and achieve the effect of improving sensitivity, improving flexibility and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings and embodiments.

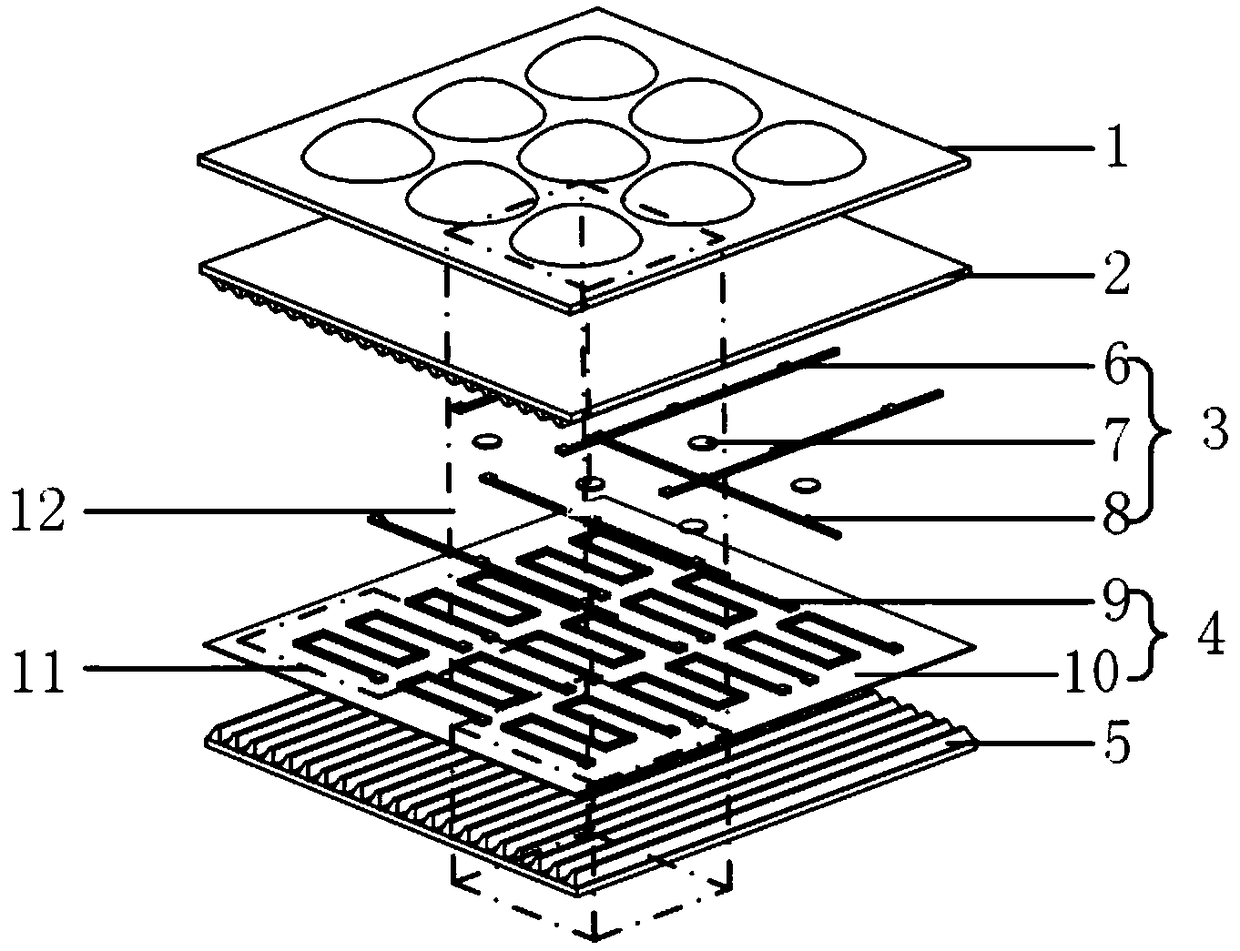

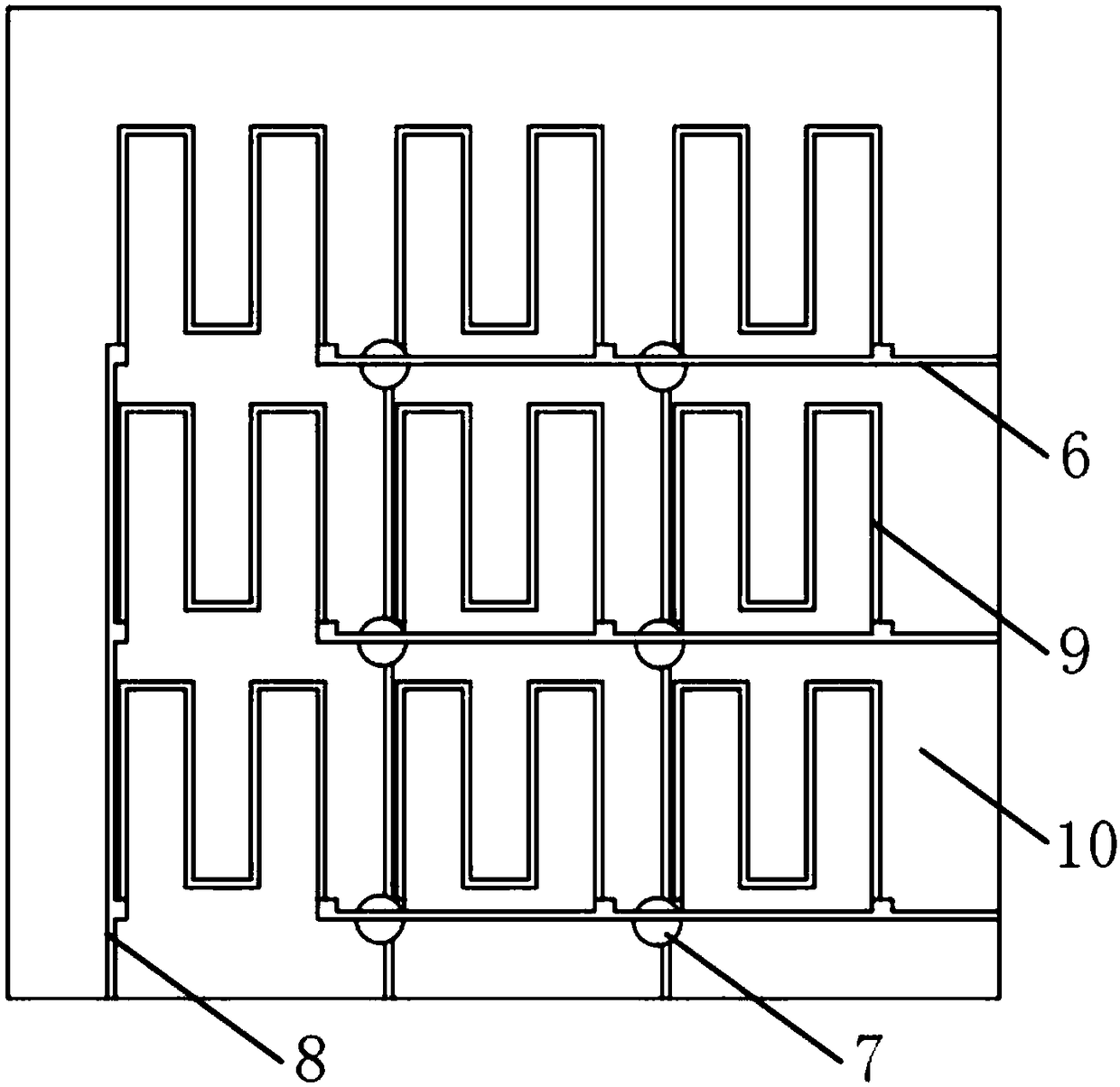

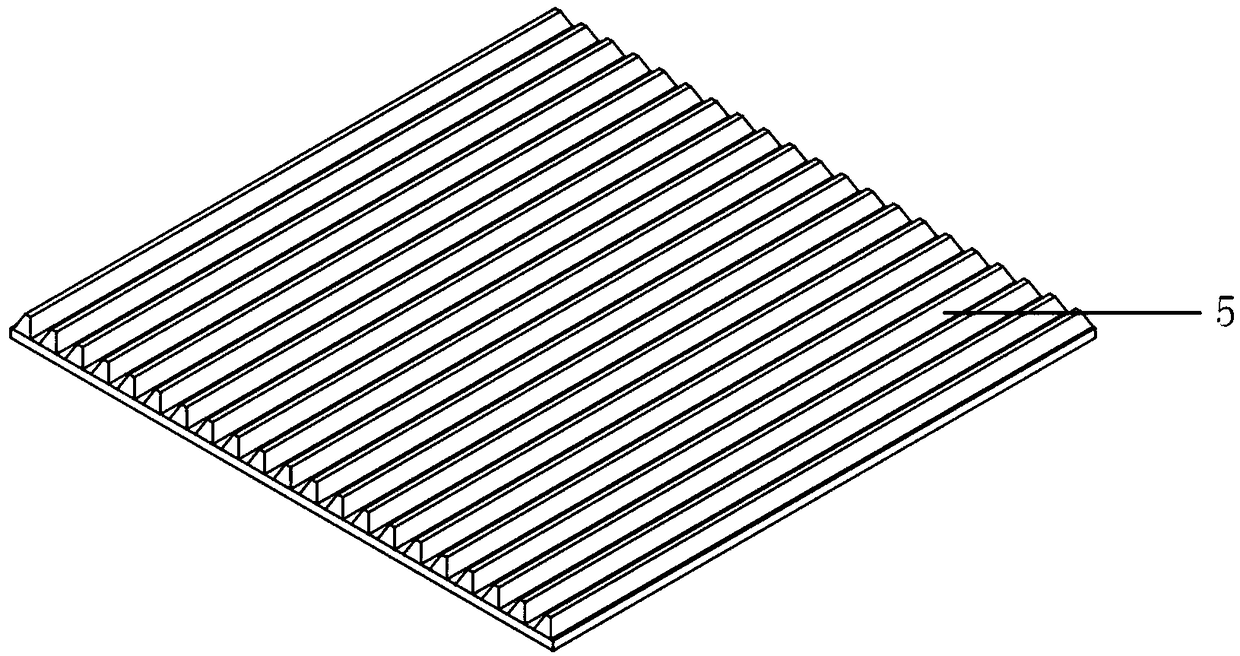

[0042] like figure 1As shown, the present invention is mainly composed of hemispherical protrusions 1, upper micro-protrusion array 2, stretchable electrode array 3, flexible pressure-sensitive array 4 and lower micro-protrusion array 5 sequentially stacked from top to bottom; The platform array 5 is used as the bottom support to form a double-layer buckle structure together with the upper micro-projection array 2 . The flexible pressure-sensitive array 4 is mainly composed of a linear graphene pattern array 9 and a flexible film substrate 10 . The hemispherical protrusion array 1 is mainly composed of a silicone rubber membrane and an array of hemispherical protrusions on the surface of the membrane. The height of a single hemispherical protrusion is 500 μm, the diameter of the bottom is 2000 μm, and the total height of the silicone rubber membrane and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

| Line spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com