Low-density material perspective imaging method and system

A technology of low-density materials and imaging methods, which is applied in the field of low-density material perspective imaging methods and systems, and can solve problems such as multiple output, wire evaluation, and qualitative accuracy of product failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

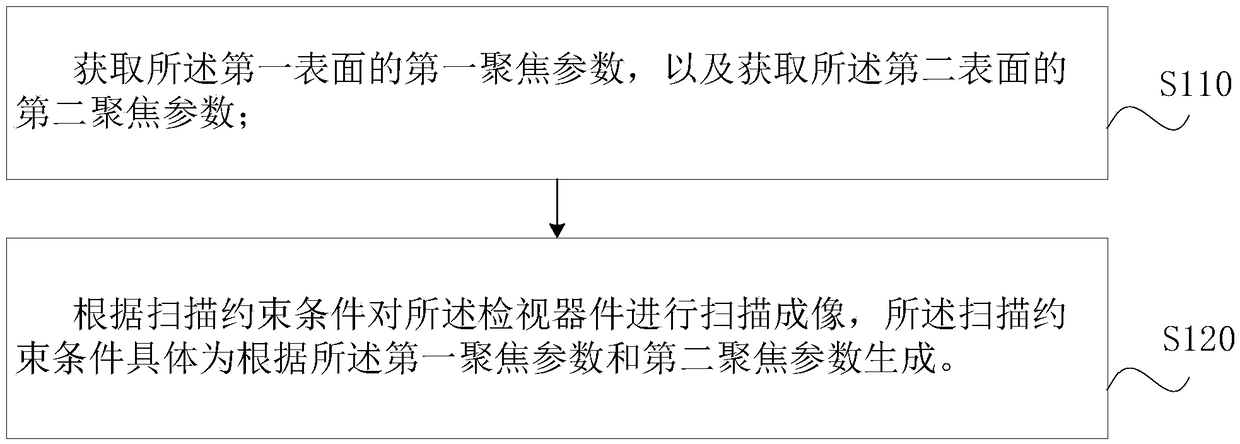

[0071] Such as image 3 It is a schematic flow chart of a low-density material perspective imaging method.

[0072] Exemplary, low-density material fluoroscopy imaging method can be used for such as Figure 4 , Figure 5 The inspection device 120 within the package body 110 of the illustrated component 100 is imaged.

[0073] The viewing device 120 includes a first element 121 having a first surface 101 , a second element 122 having a second surface 102 , and a wire 123 connecting the first surface 101 and the second surface 102 .

[0074] Such as Figure 4 and Figure 5 As shown, the first surface 101 and the second surface 102 are located on different planes. In practice, the wires 123 inside the component 100 , especially the two ends of the wires 123 are usually not on the same plane, and there is a certain height difference. Exemplary, such as Figure 4 and Figure 5 As shown, the first element 121 is the chip portion of the inspection device 120, the second eleme...

Embodiment 2

[0146] Such as Figure 16 The low-density material perspective imaging method shown is used for imaging the inspection device 120 inside the package body 110 of several components and devices 100 .

[0147] The low-density material perspective imaging method of this embodiment includes the following steps:

[0148] Step S210, arranging several components 100 in a preset manner.

[0149] Each component 100 must be free from surface defects and dirt. If there is serious dirt and highly absorbent trace contamination, such as pencil marks, etc., it needs to be cleaned.

[0150] Exemplarily, several components 100 of the same structure or type are arranged in a row, or arranged in a rectangular array, and a preset manner of arrangement can be established according to the scanning characteristics of the ultrasonic scanning device.

[0151] Step S220, scanning and imaging one of the several components 100 according to the low-density material perspective imaging method according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com