Method for testing partial discharge of suspended particles in flowing transformer oil

A technology of transformer oil and partial discharge, which is applied in the direction of instruments, measuring electricity, measuring electrical variables, etc., to achieve the effect of easy promotion, speeding up the test process, and shortening time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

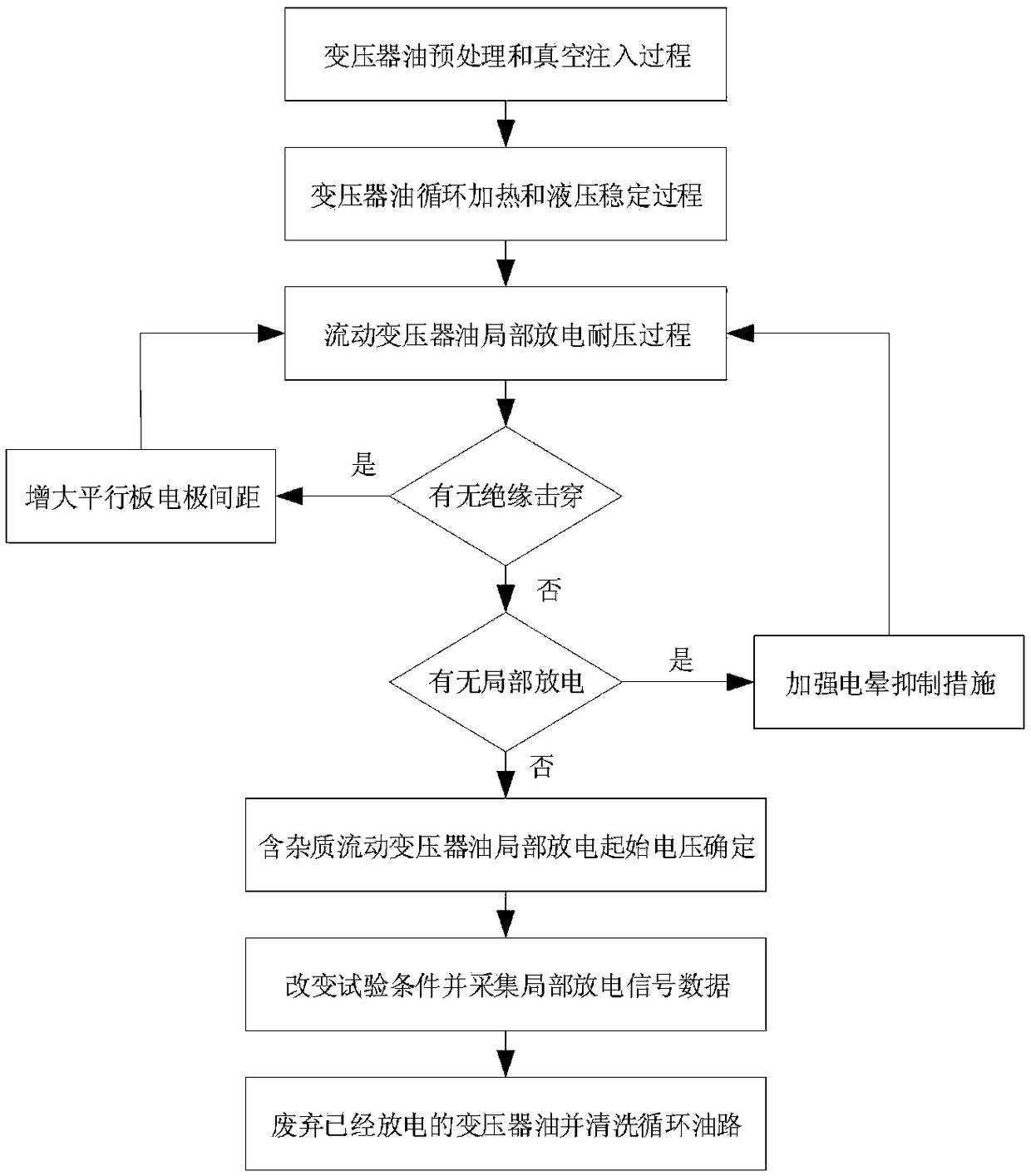

Method used

Image

Examples

Embodiment 1

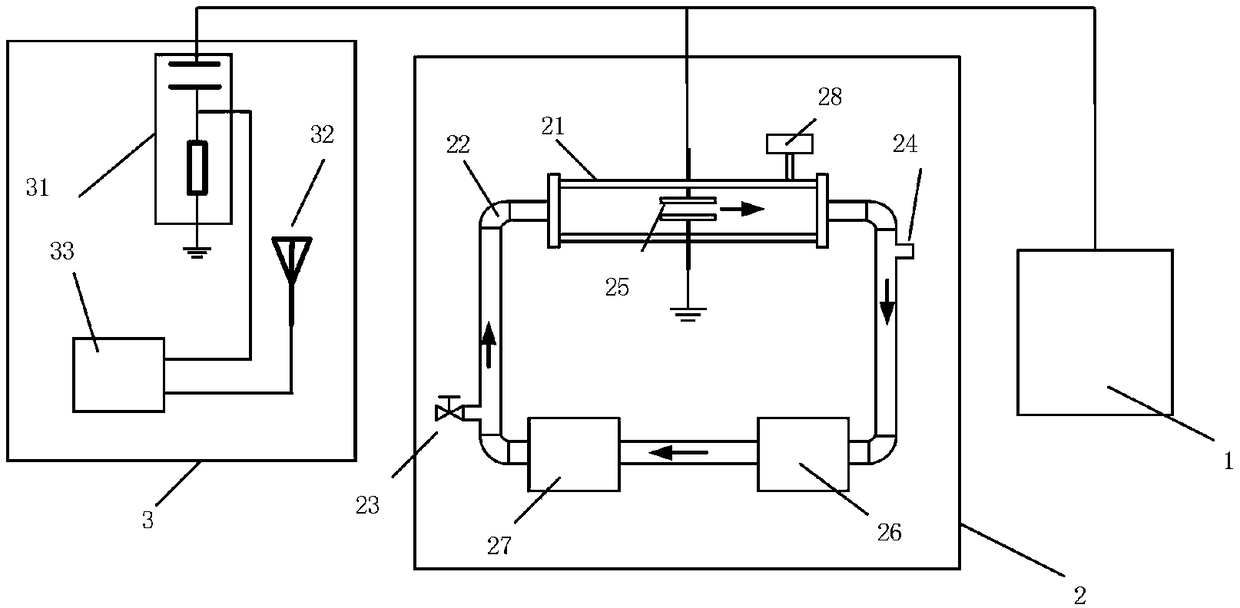

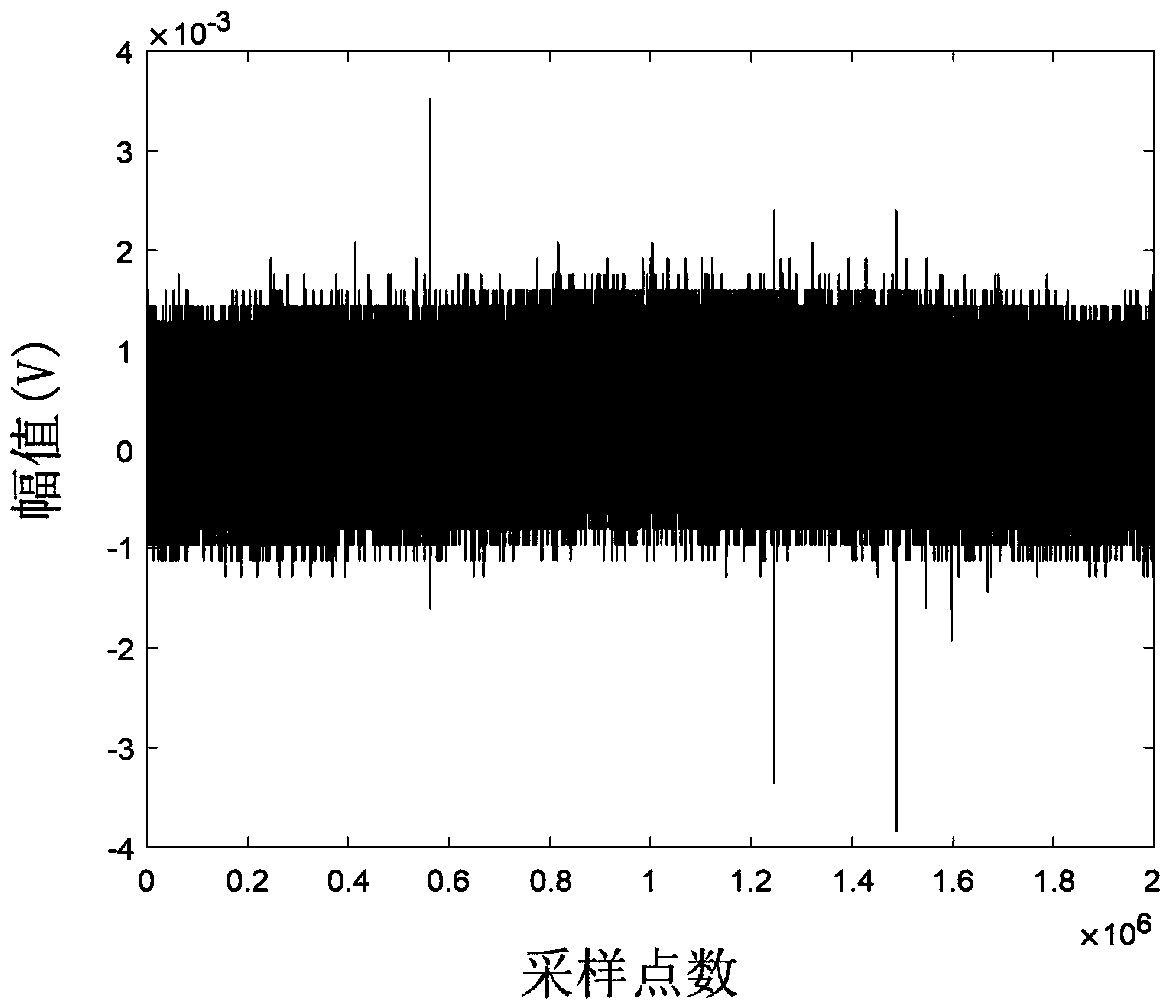

[0094] Based on attached figure 1 test method and attached figure 2 The simple mobile transformer oil suspended particle discharge generating device measures the partial discharge signal of the mobile transformer oil containing metal suspended particles within a single power frequency cycle at a flow rate of 0.06m / s.

[0095] First follow step 1);

[0096] In step 2), the temperature control component 27 heats the temperature of the transformer oil to 55° C., and the flow rate control component 26 accelerates the transformer oil to 0.06 m / s;

[0097] In step 3), no insulation breakdown occurs, and the measured maximum partial discharge amplitude is 4pC, and the partial discharge test can be carried out;

[0098] Inject spherical iron particles with a diameter of 150 μm through the suspended particle injection port 24, and the suspended particle concentration is 1.0 g / L. After waiting for 10 minutes, turn on the corona-free applied voltage pressurization device 1, and turn o...

Embodiment 2

[0101] After completing the partial discharge signal measurement of the moving transformer oil containing metal suspended particles in a single power frequency cycle in the case of a flow rate of 0.06m / s in Example 1, the transformer oil in the waste oil circulation device 2 is used Step 1) Clean the oil circulation device 2 several times with the transformer oil heated up and vacuum-dried, and repeat steps 1), 2), 4) and 5). Other conditions such as temperature and pressure remain unchanged, the difference lies in step 2) The flow rate control assembly 26 accelerates the transformer oil to 0.30 m / s. Inject spherical iron particles with a diameter of 150 μm through the suspended particle injection port 24, and the suspended particle concentration is 1.0 g / L. After waiting for 10 minutes, turn on the corona-free external voltage pressurization device 1, and turn on the partial discharge measurement device 3 to measure the local The discharge signal is gradually boosted to 18kV,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com