LED (Light Emitting Diode) lens design method for non-planar uniform illumination

A LED lens and uniform lighting technology, which is applied in lighting and heating equipment, parts of lighting devices, lighting devices, etc., can solve problems such as inability to uniform lighting, and achieve design time saving, high energy utilization, and easy processing and manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the embodiments and drawings.

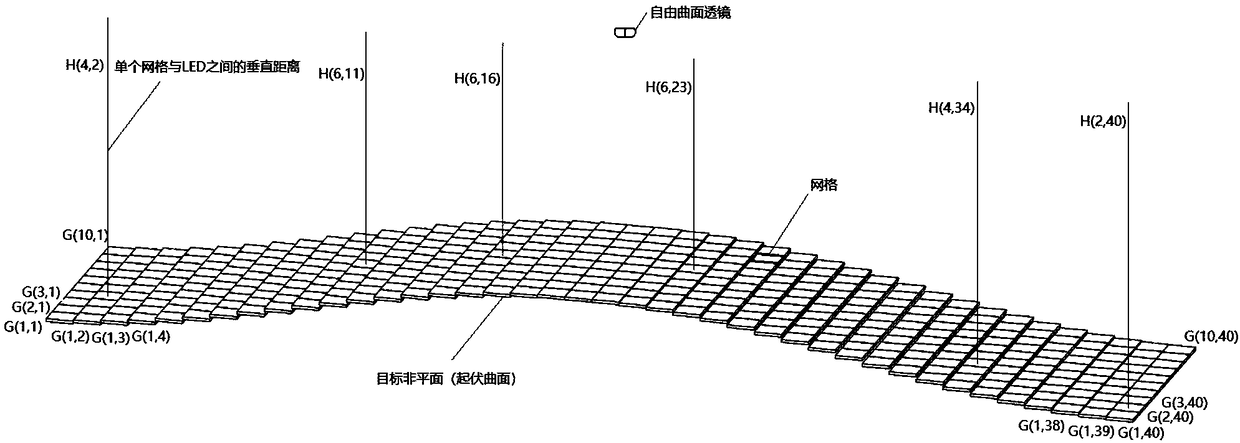

[0032] The LED lens design method for non-planar uniform illumination of the present invention specifically includes the following steps:

[0033] (1) Determine the light intensity distribution of the LED.

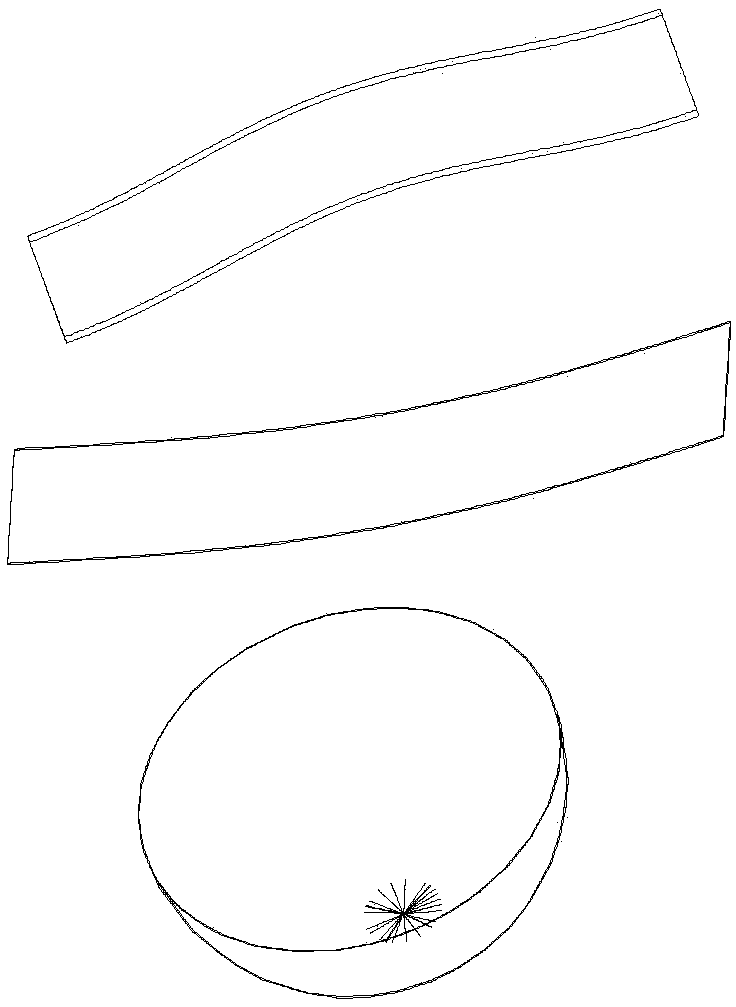

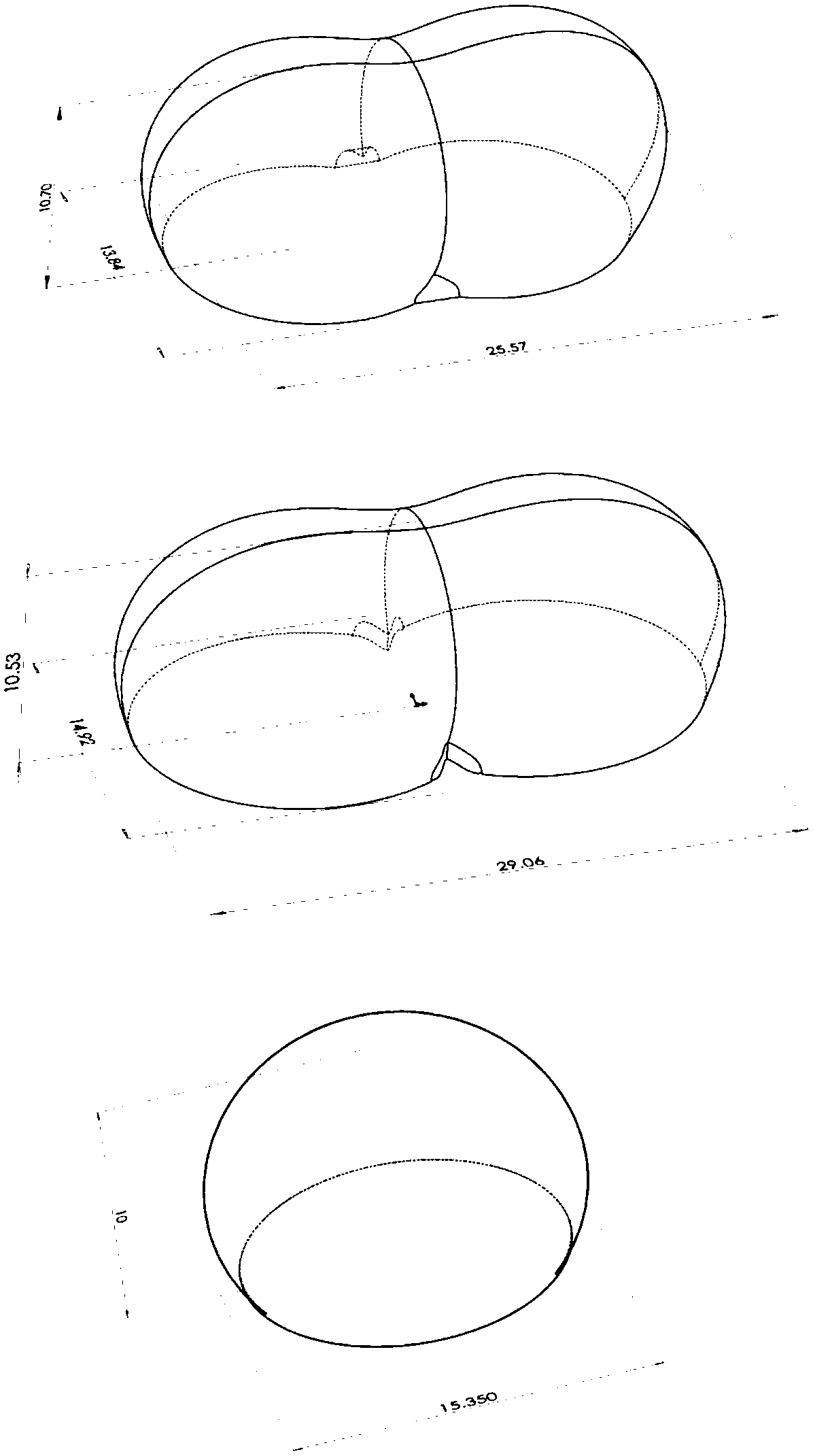

[0034] (2) In space rectangular coordinates, establish a free-form lens mathematical model based on the light intensity distribution of the LED, take the position of the LED as the origin of the coordinate, and place the target non-planar directly above the XOY plane, and the free-form lens is located between the LED and the target non-planar Between, the Z coordinate of each component should be greater than zero, the specific method is as follows:

[0035] Set the refractive index of the free-form surface material to n A , The LED is located at the origin of the Cartesian coordinate system, under normal temperature conditions, the refractive index of air is set to n B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com