Universal low-temperature constant-humidity thermal refining unit for granary

An all-round, granary technology, applied in air humidification systems, high-efficiency regulation technology, agricultural machinery and implements, etc., can solve the problems of large repeated investment in low-temperature grain storage equipment, insufficient equipment functional compatibility, and different temperature and humidity requirements, and achieve The effect of good energy saving, stable humidity and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

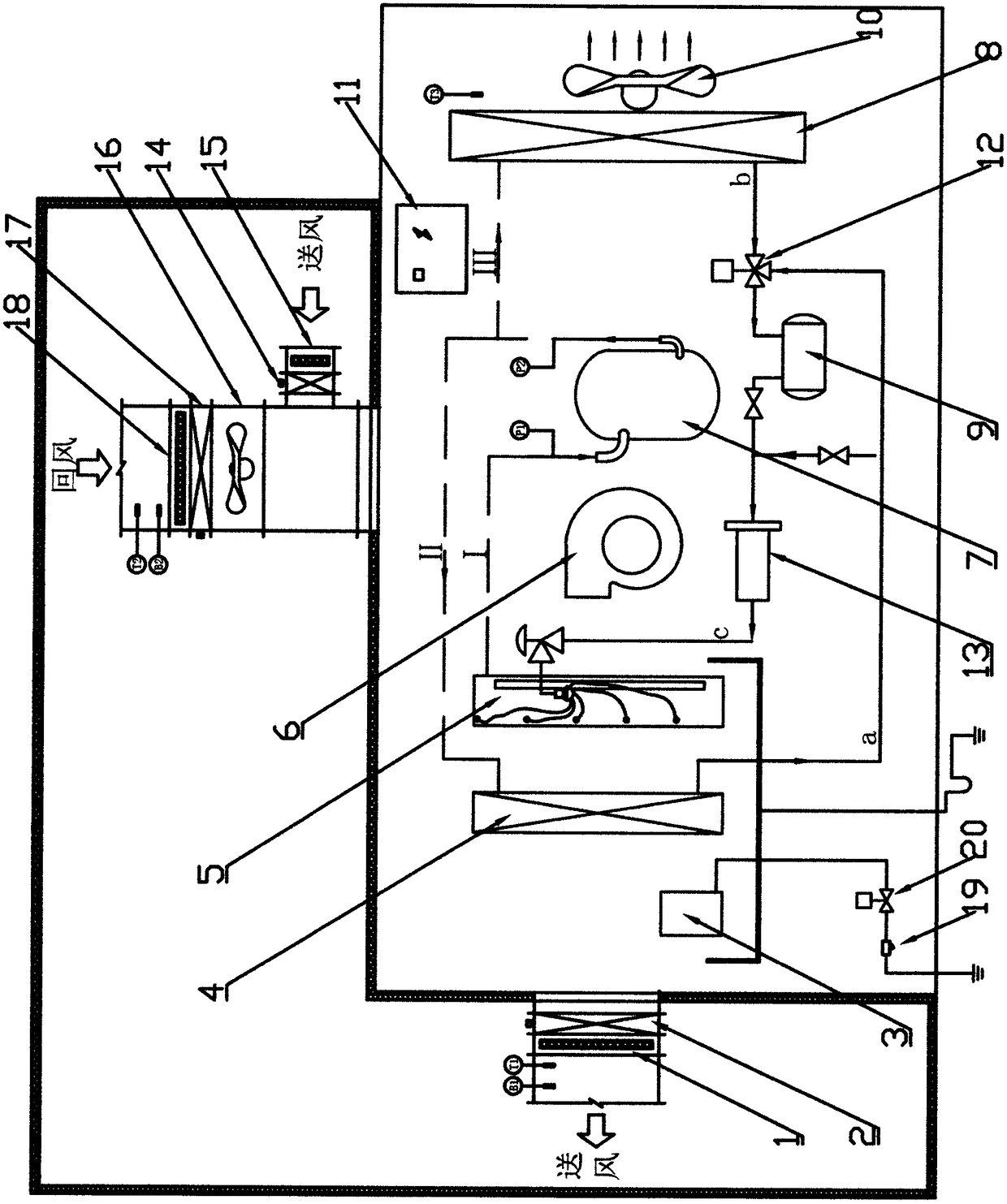

[0048] As an implementation, the sensors include 2 humidity sensors (B1, B2), 3 temperature sensors (T1, T2, T3) and 2 pressure sensors (P1, P2), all of which are electrically connected to the PLC electrical control box (11) connect. Humidity sensors (B1, B2) are installed outside the first air filter (1) and outside the third air filter (18). The temperature sensors (T1, T2, T3) are installed outside the first air filter (1), outside the third air filter (18) and at the condenser (8). Pressure sensors (P1, P2) are installed at both ends of the inlet and outlet of the compressor (7).

[0049] As an implementation, the PLC electrical control box (11) is provided with a remote control unit, which can be controlled by the remote information terminal of the granary or the remote control terminal is controlled by a mobile phone.

[0050] The unit of the present invention can set four working conditions:

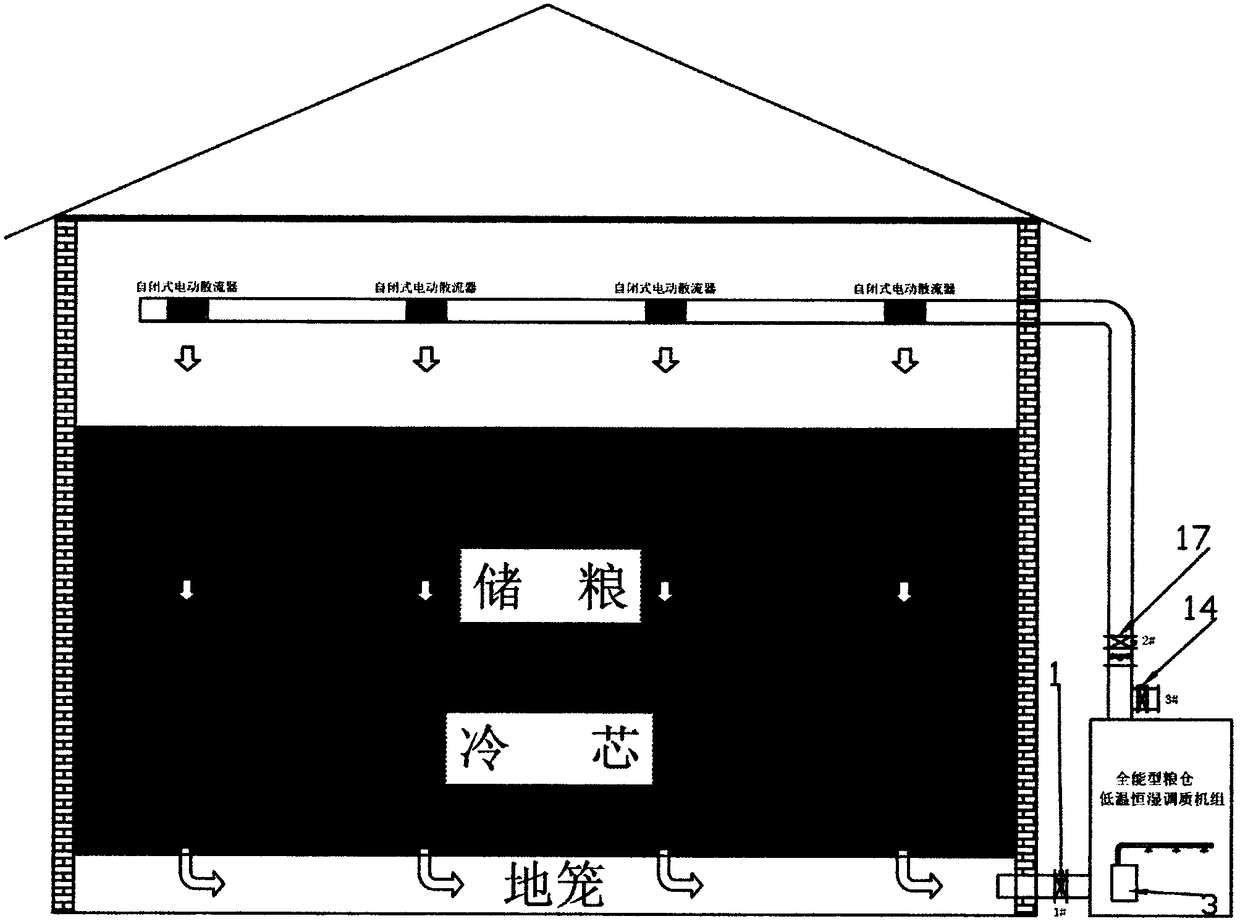

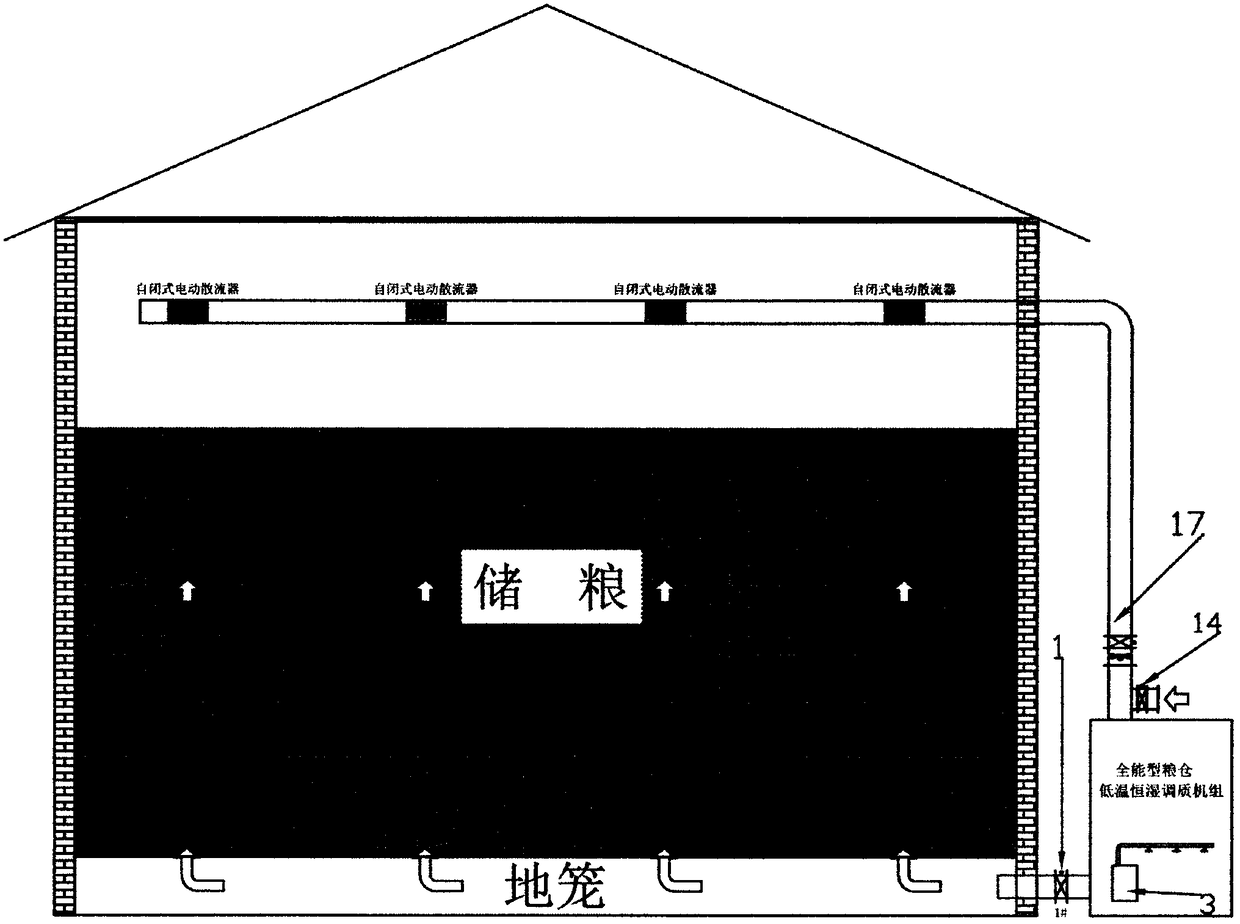

[0051] 1) Internal circulation ventilation mode; such as figure 2 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com