Preparation method of flocculant for textile printing and dyeing wastewater decolorization

A decolorizing flocculant, textile printing and dyeing technology, applied in textile industry wastewater treatment, chemical instruments and methods, flocculation / sedimentation water / sewage treatment, etc. and other problems, to achieve high chromaticity and COD removal rate, low temperature storage stability, and the effect of reducing water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

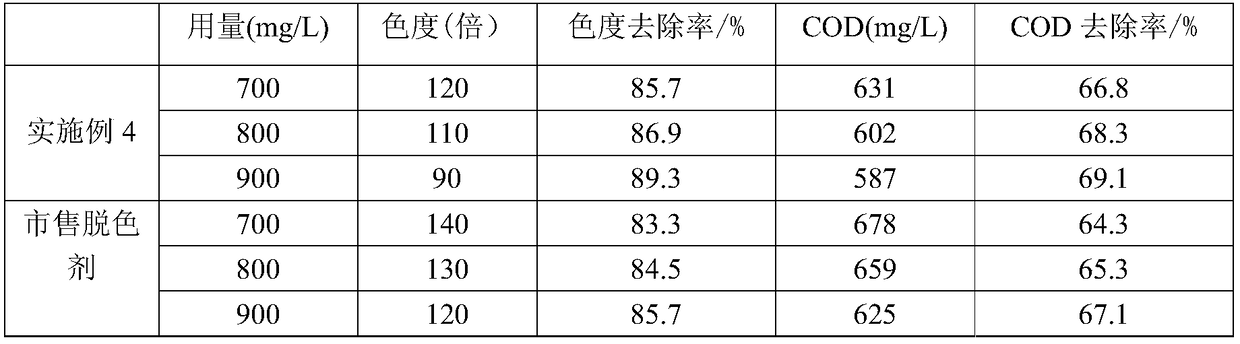

Examples

Embodiment 1

[0013] Embodiment 1, concrete steps are:

[0014] 1) Add 105 kilograms of formaldehyde solution, 66 kilograms of dicyandiamide and 6.42 kilograms of ammonium chloride with a mass concentration of 37% in turn in the enamel kettle A equipped with a reflux condenser and coil heating / cooling, heat to 50 ° C and stir 30 minutes until the solution is transparent;

[0015] 2) Dissolve 15.95 kg of paraformaldehyde in 18.52 kg of NaOH solution with a concentration of 2-4mol / L in reactor B, heat to 60°C and stir to dissolve it;

[0016] 3) Add the solution obtained in step 2) into the enamel kettle A, make the pH of the solution in the enamel kettle A be 7.5±0.2, continue heating to 80°C for 1 hour;

[0017] 4) Add 25.68 kg of ammonium chloride into the enamel kettle A, keep the reaction at 80°C for 3 hours, let it cool down to room temperature after the reaction, and obtain the decolorizing flocculant for textile printing and dyeing wastewater.

Embodiment 2

[0019] 1) Add 125 kg of formaldehyde solution with a mass concentration of 37%, 75.6 kg of dicyandiamide and 8.0 kg of ammonium chloride in sequence in the enamel kettle A equipped with a reflux condenser and coil heating / cooling, heat to 45°C and stir 30 minutes until the solution is transparent;

[0020] 2) Dissolve 20.97 kg of paraformaldehyde in 23.1 kg of NaOH solution with a concentration of 2.5 mol / L in reactor B, heat to 65°C and stir to dissolve it;

[0021] 3) Add the solution obtained in step 2) into the enamel kettle A, so that the pH of the solution in the enamel kettle A is 7.5±0.2, and continue heating to 75° C. for 2 hours;

[0022] 4) Add 32 kg of ammonium chloride into the enamel kettle A, keep it at 75° C. for 2 hours, and let it cool down to room temperature after the reaction, to obtain the decolorizing flocculant for textile printing and dyeing wastewater.

Embodiment 3

[0024] 1) Add 136 kilograms of formaldehyde solution, 80 kilograms of dicyandiamide and 11.4 kilograms of ammonium chloride successively with a mass concentration of 37% in the enamel kettle A equipped with a reflux condenser and coil heating / cooling, heat to 45 ° C and stir 25 minutes until the solution is transparent;

[0025] 2) Dissolve 23.93 kg of paraformaldehyde in 25 kg of NaOH solution with a concentration of 3 mol / L in reactor B, heat to 70°C and stir to dissolve it;

[0026] 3) Add the solution obtained in step 2) into the enamel kettle A, make the pH of the solution in the enamel kettle A be 7.7±0.2, continue heating to 70°C for 2 hours;

[0027] 4) Add 34.2 kg of ammonium chloride into the enamel kettle A, keep the reaction at 70°C for 1 hour, and let it cool down to room temperature after the reaction, to obtain the decolorizing flocculant for textile printing and dyeing wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com