Drainage pipe

A drainage tube and tube body technology, applied in the field of drainage tubes, can solve problems such as cumbersome operation and blockage, and achieve the effects of reducing manual operation, maintaining smoothness and improving use efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

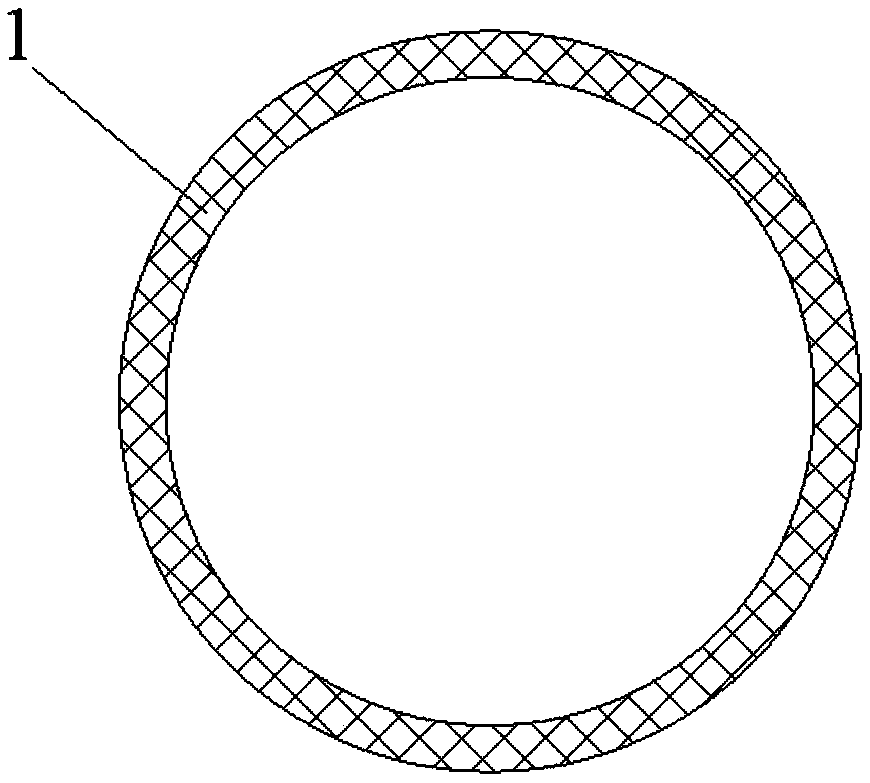

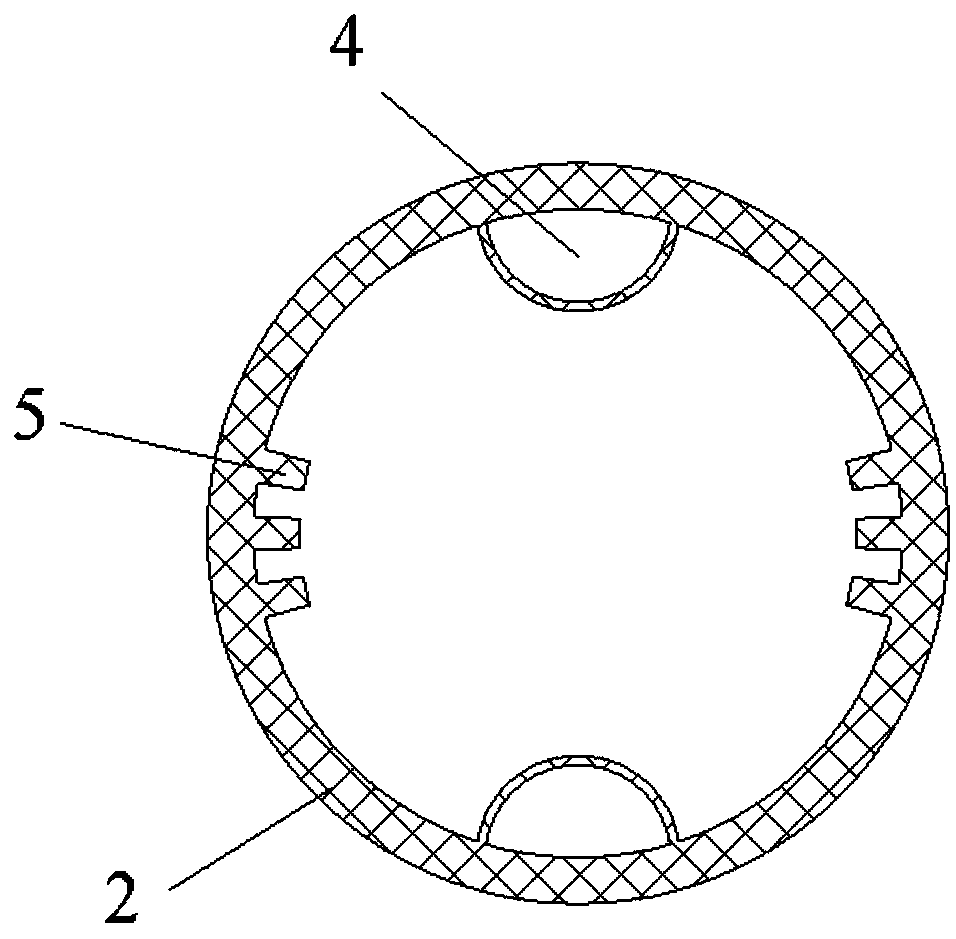

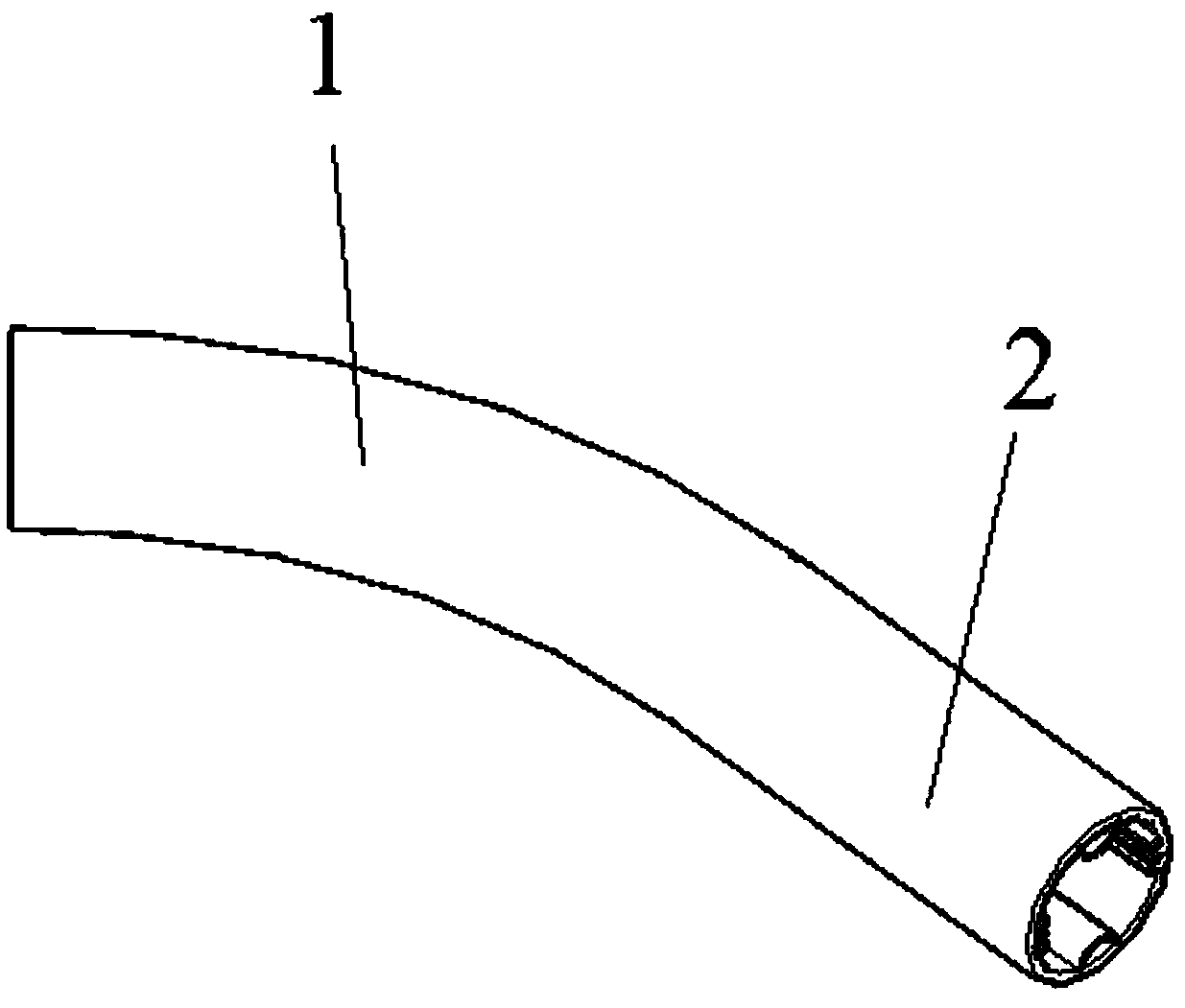

[0052] An exemplary embodiment of the present invention, such as Figure 1~3 As shown, a drainage tube includes a first tube body 1 and a second tube body 2, the second end of the first tube body 1 is connected to the first end of the second tube body 2, the first tube body 1 and the second tube body The pipe body 2 is integrally formed.

[0053] The first tube body 1 is a hollow tube made of transparent silica gel.

[0054] The inner diameter of the first pipe body 1 is equal to the inner diameter of the second pipe body 2 , and the outer diameter of the first pipe body 1 is equal to the outer diameter of the second pipe body 2 .

[0055] The length of the first pipe body 1 is greater than or equal to the length of the second pipe body 2 .

[0056] In this embodiment, preferably, the length of the first pipe body 1 is greater than the length of the second pipe body 2 , and the ratio of the length of the first pipe body 1 to the length of the second pipe body 2 is greater th...

Embodiment 2

[0072] This embodiment is a preferred embodiment of the present invention. The difference between this embodiment and Embodiment 1 lies in that the second pipe body 2 has a different structure and includes a third pipe body 3 .

[0073] A drainage tube in this embodiment includes a first tube body 1, a second tube body 2 and a third tube body 3, the second end of the first tube body 1 is connected to the first end of the second tube body 2, the second tube body 2 The first end of the three pipe bodies 3 is connected to the second end of the second pipe body 2 , and the first pipe body 1 , the second pipe body 2 and the third pipe body 3 are integrally formed.

[0074] Wherein, the structure of the first pipe body 1 is the same as that of Embodiment 1, and will not be repeated here.

[0075] The inner diameter of the first pipe body 1, the inner diameter of the second pipe body 2 and the inner diameter of the third pipe body 3 are equal, the outer diameter of the first pipe bod...

Embodiment 3

[0100] This embodiment is a preferred embodiment of the present invention, and the difference between this embodiment and Embodiment 2 lies in that the structures of the second pipe body 2 and the third pipe body 3 are different.

[0101] A drainage tube in this embodiment includes a first tube body 1, a second tube body 2 and a third tube body 3, the second end of the first tube body 1 is connected to the first end of the second tube body 2, the second tube body 2 The second end of the second pipe body 2 is connected to the first end of the third pipe body 3 , and the first pipe body 1 , the second pipe body 2 and the third pipe body 3 are integrally formed.

[0102] Further, in this embodiment, the ratio of the length of the first pipe body 1 to the length of the second pipe body 2 is 10:1, and the ratio of the length of the second pipe body 2 to the length of the third pipe body 3 is 2 :1.

[0103] Wherein, the structure of the first pipe body 1 is the same as that of Embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com