A dual-stroke reciprocating mixing process with instant instructions

A mixing process and reciprocating technology, which is applied to mixer accessories, mixers with rotating stirring devices, manufacturing tools, etc., can solve problems such as low work efficiency, poor product quality, and weak operation prompting effect, and achieve high work efficiency. Good product quality and strong operation prompt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

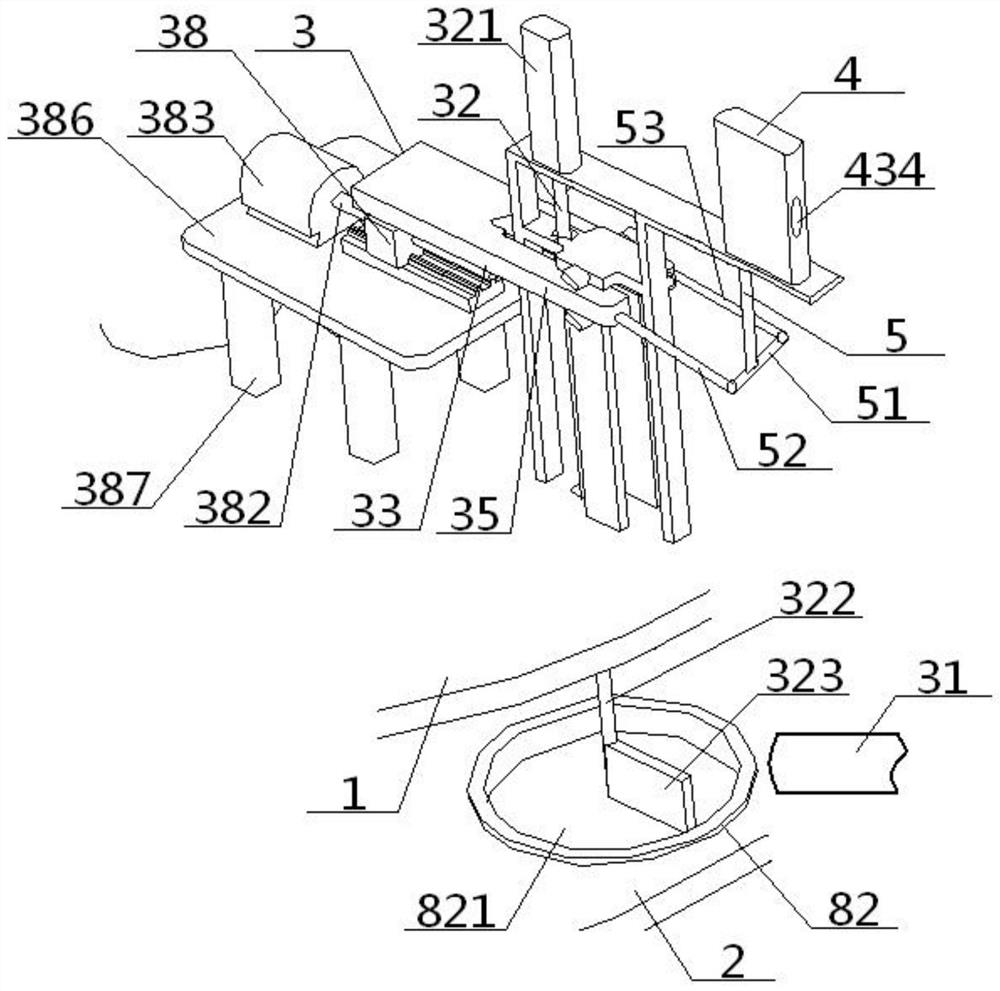

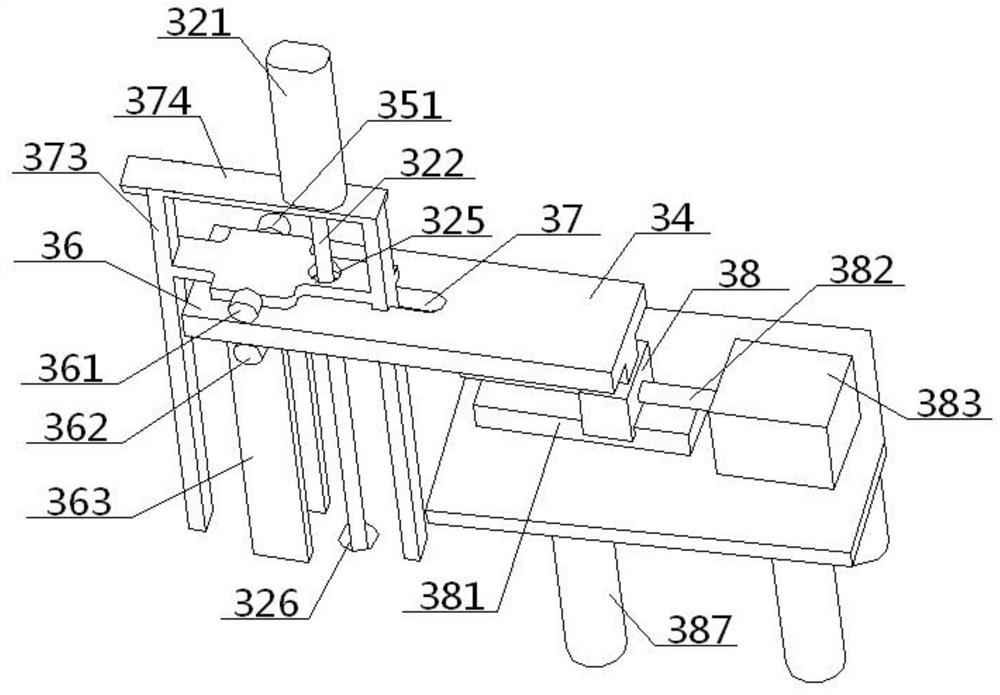

[0053] see Figure 1 to Figure 8 , a two-stroke reciprocating mixing process with instant instructions, including a sequential feeding step and a mixing step, the feeding step refers to adding particles from the external adding unit 31 to the mixing chamber 821, and the mixing step refers to first The lifting motor 321 in the lifting unit 32 drives the stirring member 323 down through the lifting rod 322 until the stirring member 323 falls into the inside of the particles accumulated in the stirring chamber 821, and then the middle part of the horizontal drive unit 33 is set on the middle part of the lifting rod 322 The horizontal driving platform 324 that is provided carries out the horizontal driving operation so that the elevating rod 322 and the stirring member 323 are rotated together, and then the particles in the stirring chamber 821 are stirred by the rotating stirring member 323; the horizontal driving operation includes moving forward Steps and return steps, the forw...

Embodiment 2

[0055] Basic content is the same as embodiment 1, the difference is:

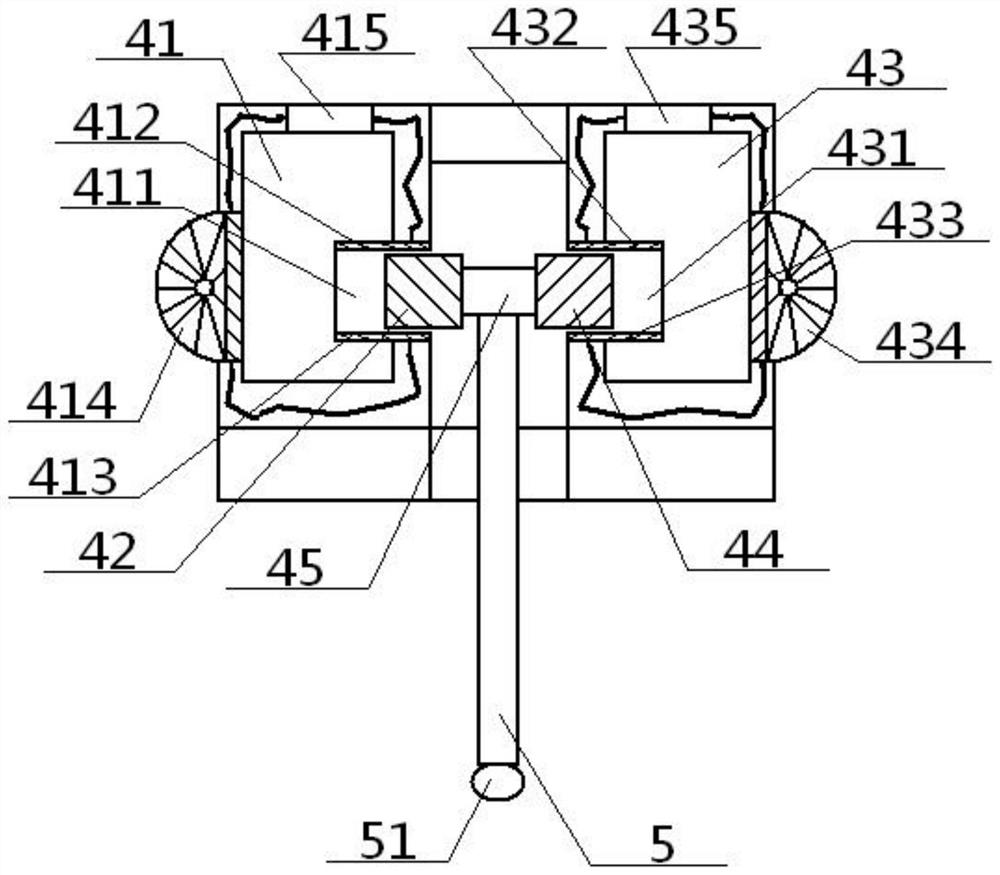

[0056] The return indication unit 41 includes a return indicator light 414, a left power supply box 415, an upper left power supply piece 412 and a lower left power supply piece 413. Carry out circuit connection, upper left energizing sheet 412, left lower energizing sheet 413 clamp up and down to become return energizing groove 411, this return energizing groove 411 and the outer end of the left switching sheet 42 sandwiched therebetween carry out insertion fit; Including the forward indicator light 434, the right power supply box 435, the upper right energizing sheet 432 and the lower right energizing sheet 433, the upper right energizing sheet 432 is connected to the lower right energizing sheet 433 through the right power supply box 435, the forward indicator light 434, and the lower right energizing sheet 433 successively. Connect, the upper right energizing sheet 432, the lower right energizing sheet ...

Embodiment 3

[0059] Basic content is the same as embodiment 1, the difference is:

[0060] The stirring chamber 821 is set inside the No. 2 groove 82, the outside of the No. 2 groove 82 is embedded on the disk surface of the rotating flat disk 2, and the fixed flat disk 1 parallel to it is arranged above the rotating flat disk 2. A lifting unit 32 and a horizontal driving unit 33 are arranged on the disk surface of the flat disk 1. The lifting unit 32, the horizontal driving unit 33, and the external adding unit 31 constitute the particle adding device 3 together. The lifting unit 32 includes a lifting motor 321 and a lifting rod 322. With the stirring member 323, the lifting motor 321 is set higher than the fixed flat plate 1, the output end of the lifting motor 321 is connected with the top of the lifting rod 322, and the bottom end of the lifting rod 322 is connected with the stirring member 323 after passing through the fixed flat plate 1 , the stirring member 323 is located directly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com