Optimization method for thickness uniformity of irregular planes and polygonal coating layers by electrostatic spraying robot

A technology of electrostatic spraying and coating thickness, applied in liquid spraying equipment, spraying devices, etc., can solve the problems of reducing spraying operation efficiency, paint waste, and uniformity not reaching the target.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

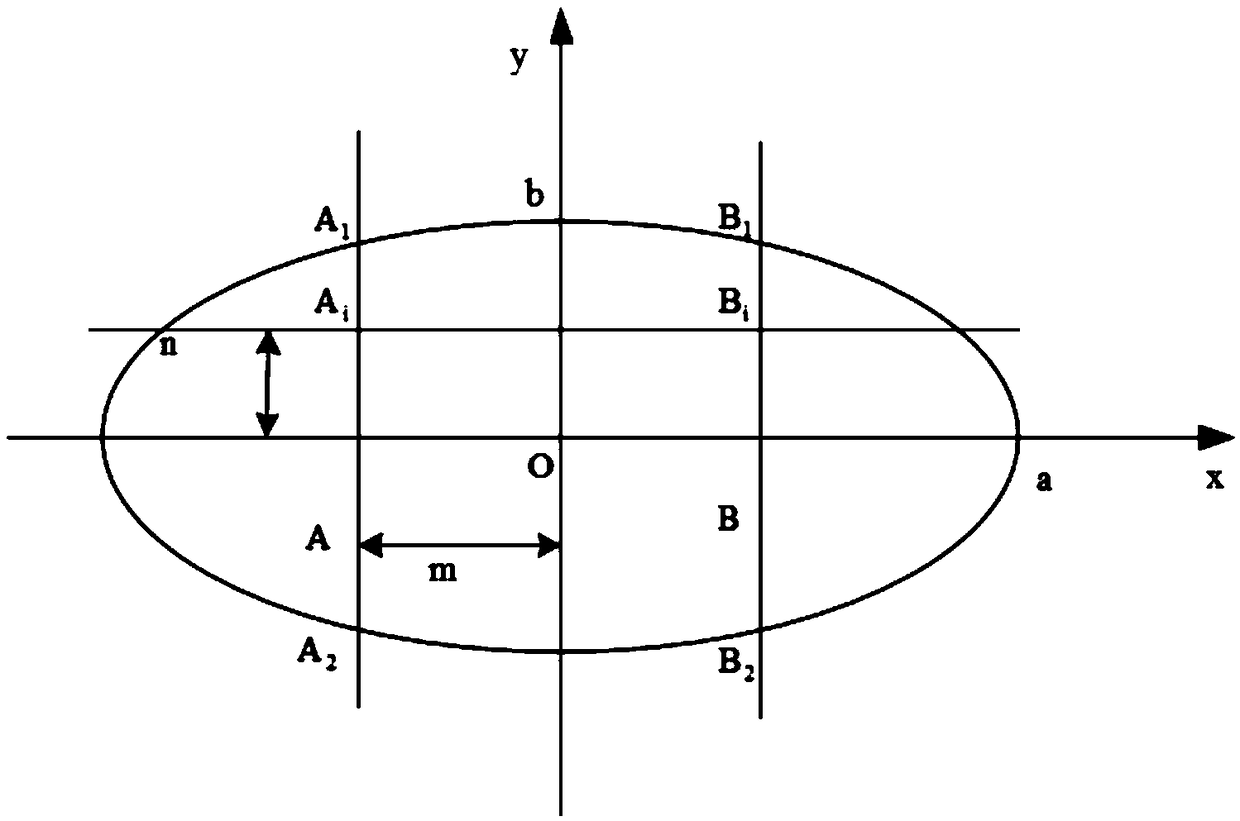

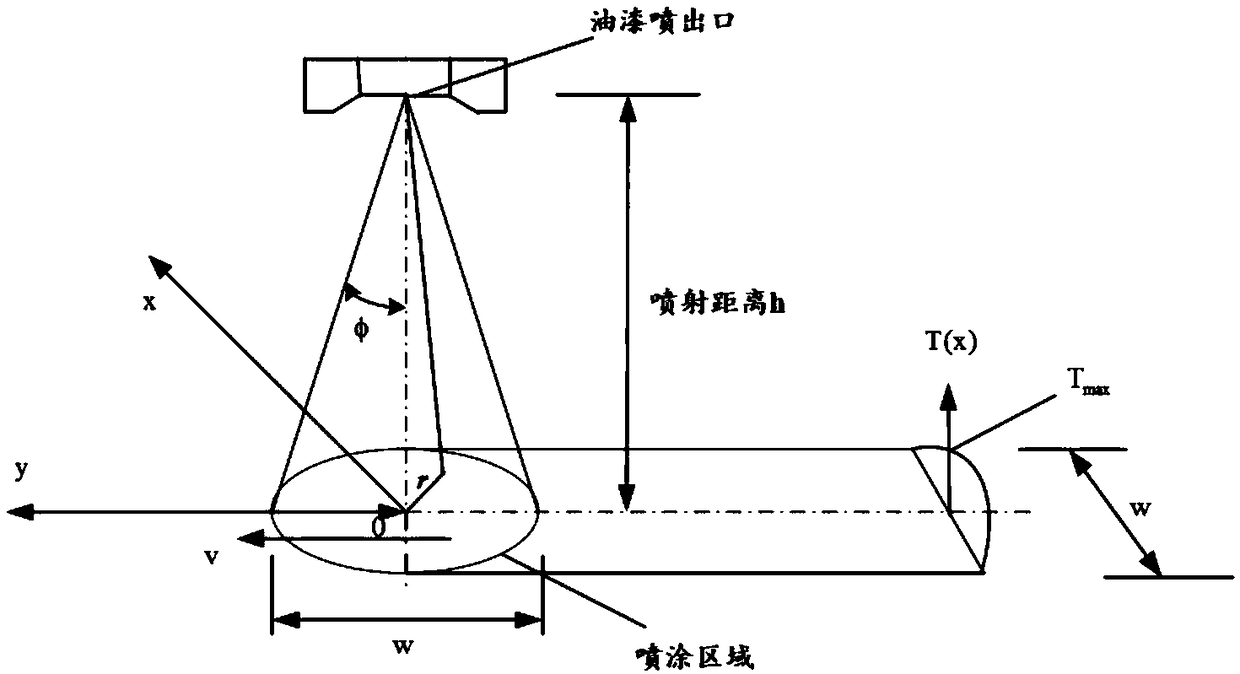

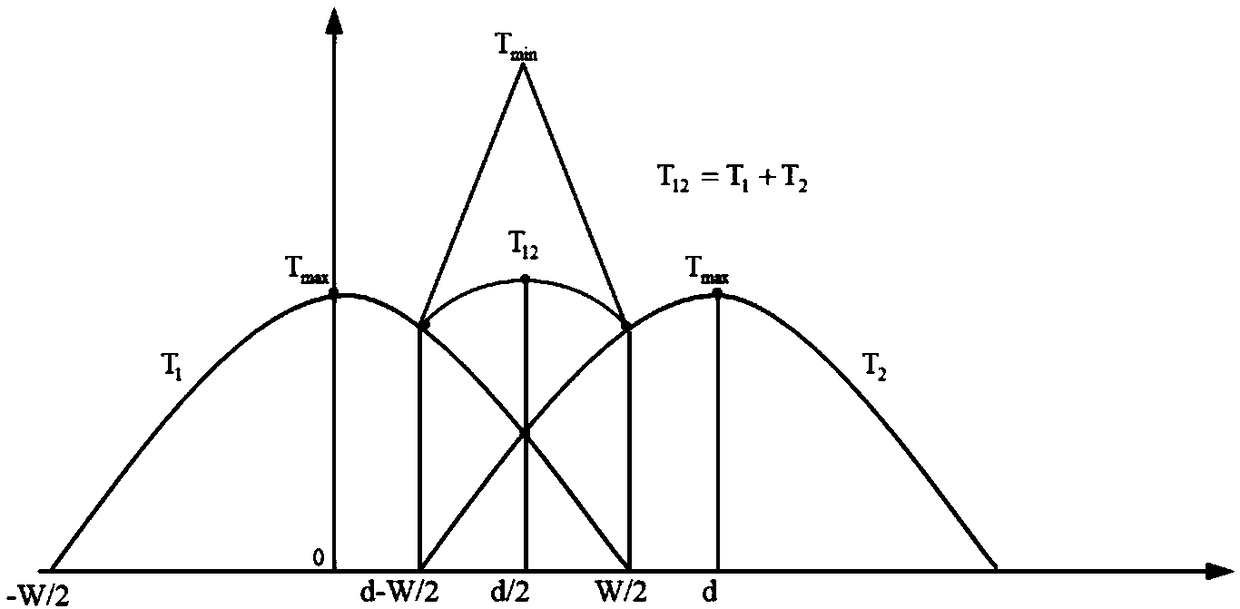

[0072] 1. Establish the mathematical model of spray gun trajectory and the spatial distribution model of paint

[0073] 1.1. Assume that the workpiece is stationary, and use the Cartesian coordinate system XYZ to describe its position and shape. Suppose the workpiece surface can be expressed as a function z=h(x, y). From the general set concept, the function expression of the workpiece surface can be defined as:

[0074] S={(x,y,z)|z=h(x,y),(x,y)∈D}

[0075] Among them, the mapping h: D→R (real number field), the domain of definition

[0076] The pose is represented by the Cartesian coordinate system XYZ, and the three-dimensional vector functions P(t) and 0(t) are respectively used to represent the position and direction of the spray gun in the fixed Cartesian coordinate system. The relationship between these two vectors and time t can be expressed as for:

[0077] P(t)=[p x (t), p y (t), p z (t)]

[0078] O(t)=[o x (t), o y (t), o z (t)]

[0079] Among them, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com